Load maintaining valve

A technology of load holding valve and holding valve, applied in the field of hydraulic valves, which can solve the problems of low pressure loss of balance valves, unadjustable oil pipes or shutting down flow of oil cylinders, etc., to achieve stable and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

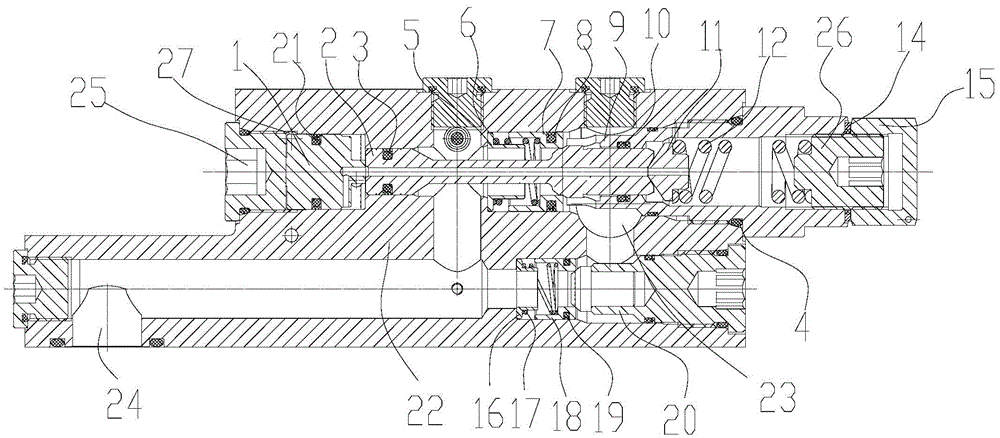

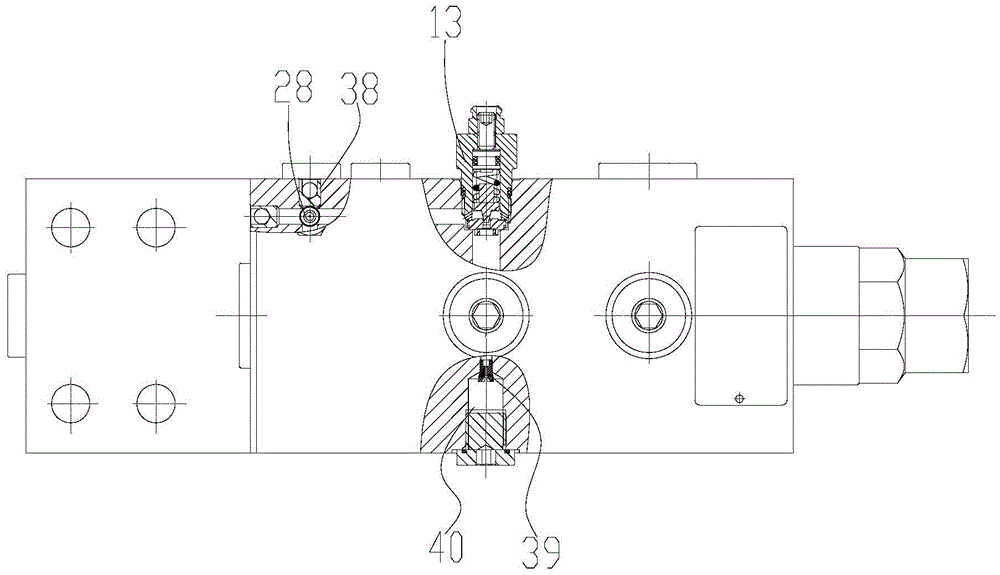

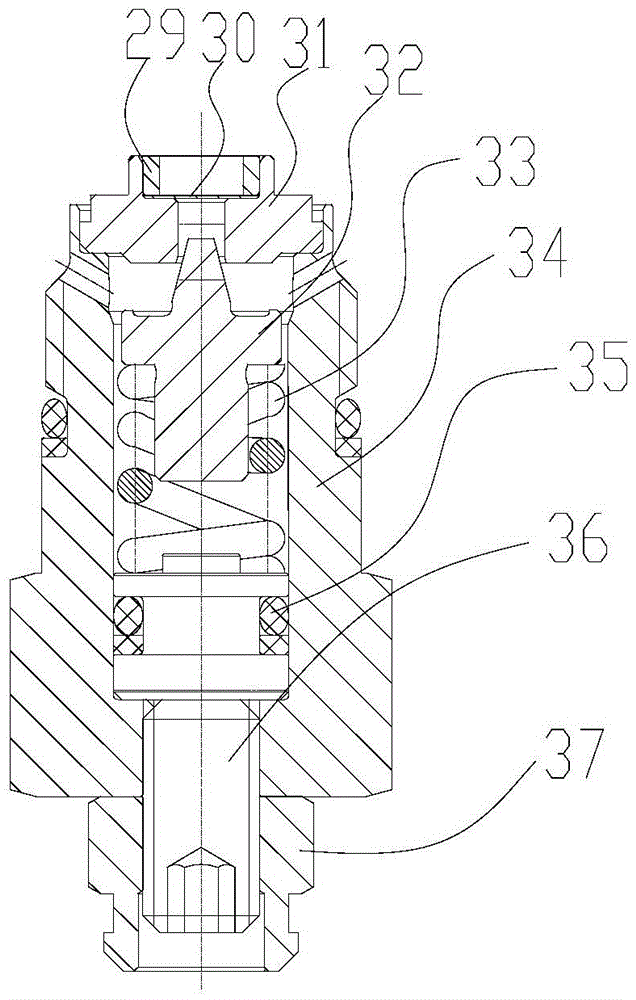

[0035] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

[0036] For the load holding valve in this solution, by opening two one-way valve ports, the load chamber is pressurized and the load is pushed, so that the pressure caused by the load acts on the one-way valve core and pushes it to the main valve core. Therefore, the oil is blocked in the oil cylinder and becomes a non-leakage state; when it is necessary to unload, the main valve core is pushed away from the one-way valve core by a sufficiently high control pressure.

[0037] At the same time, the load holding valve also has a plug-in safety valve, which can be opened when overload or vibration occurs, so that the load can be unloaded without controlling oil when overload or vibration occurs.

[0038] In addition, in actual implementation, the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com