Online analysis system of ship exhaust emission

A waste gas emission and analysis system technology, applied in the direction of material analysis, material analysis by optical means, sampling, etc., can solve the problems of expensive equipment, low measurement accuracy of NO2 gas, and large volume, so as to achieve small maintenance workload and reliable Good maintainability and stability, simple system structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

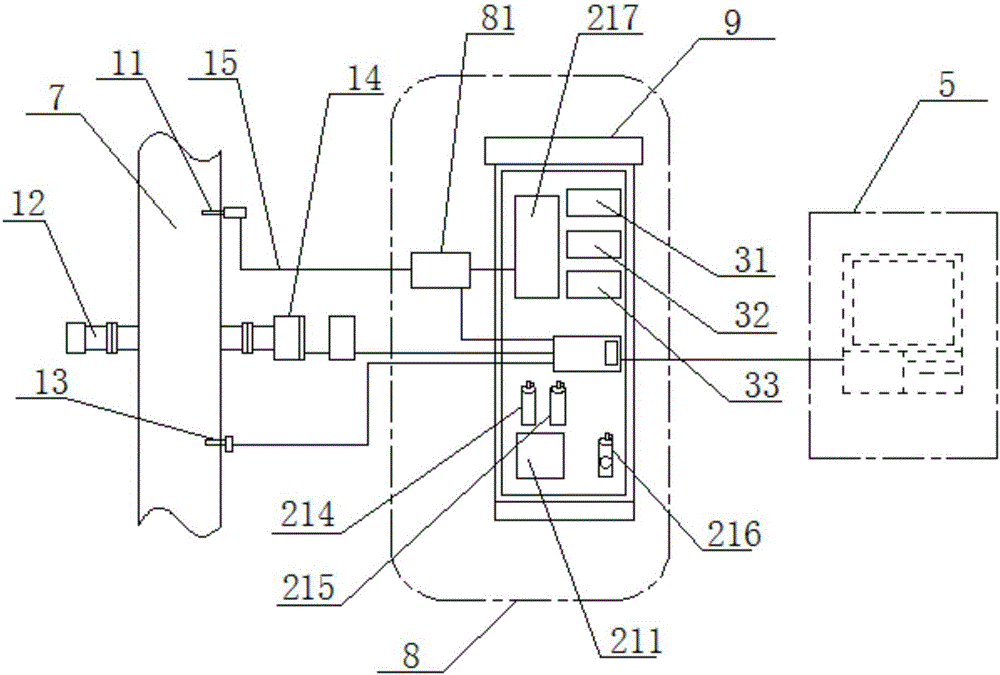

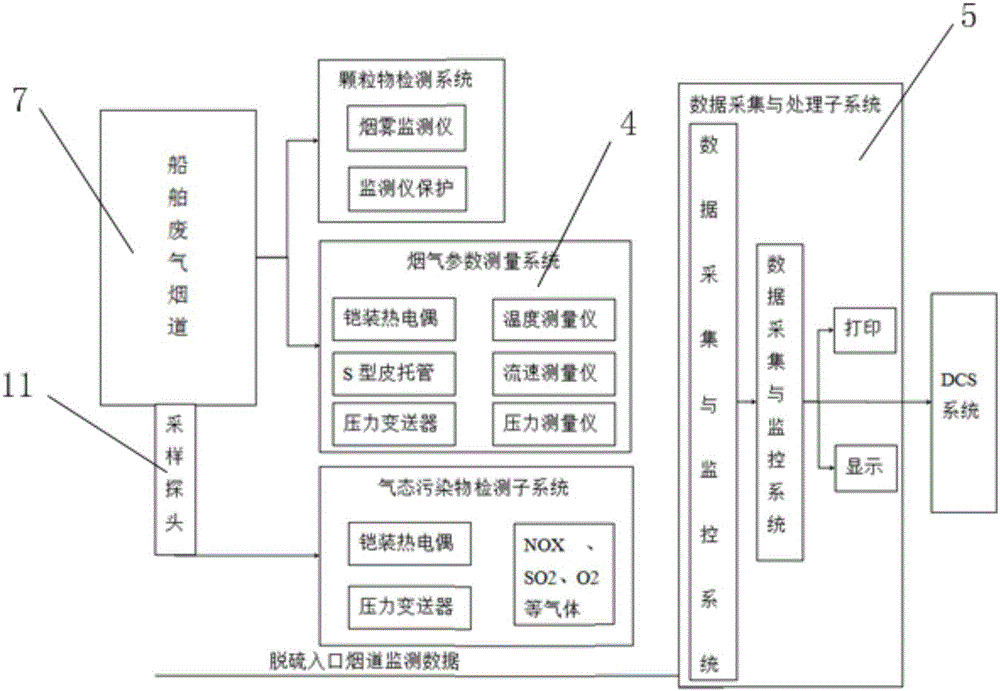

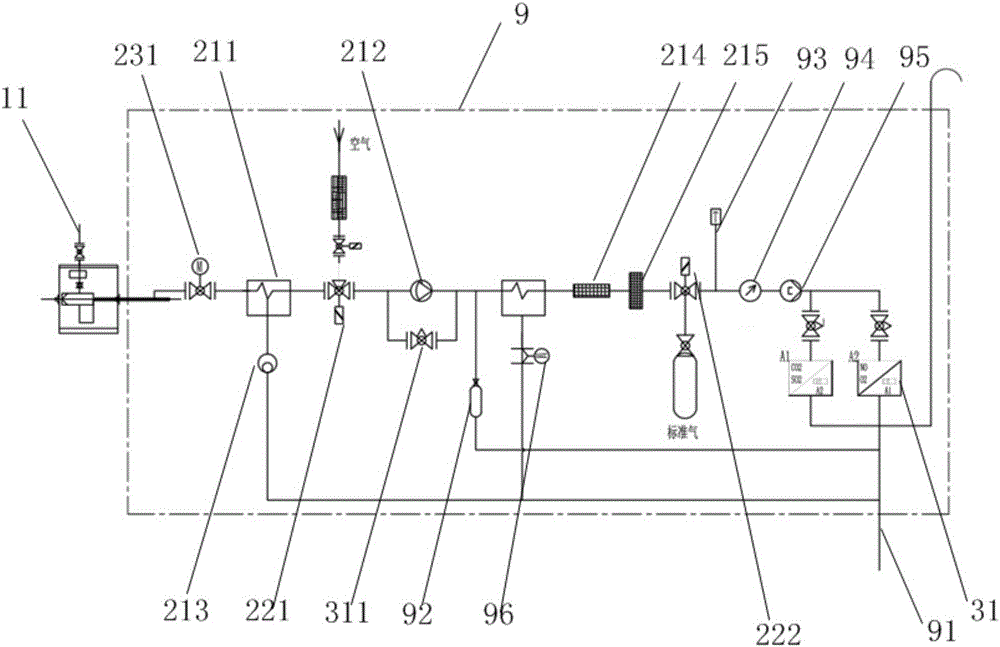

[0024] refer to figure 1 , figure 2 , image 3 with Figure 4, the present invention includes a flue gas sampling unit 1, a flue gas pretreatment device 2, a flue gas analysis system 3, a flue gas parameter measurement system and an automatic blowback control system 4, a data acquisition and processing system (DAS) 5, and a flue dust monitoring system 6 , flue 7, gas testing room 8, analysis instrument cabinet 9, the flue gas sampling unit 1, flue gas pretreatment device 2, flue gas analysis system 3, flue gas parameter measurement system and automatic backflush control system 4, data The acquisition and processing system (DAS) 5 and the smoke monitoring system 6 are connected in sequence; the flue gas sampling unit 1 includes a sampling probe 11, a smoke meter 12, a flow meter 13, a moisture meter 14, a pressure sensor, and a temperature sensor; the flue gas The pretreatment device 2 includes a sample gas pretreatment unit, calibration equipment, and a purging unit; the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com