Scroll compressor

A scroll compressor and moving scroll technology, applied in the field of compressors, can solve problems such as low oil discharge rate, achieve the effects of reducing friction and wear, reducing exhaust noise, and flexible design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

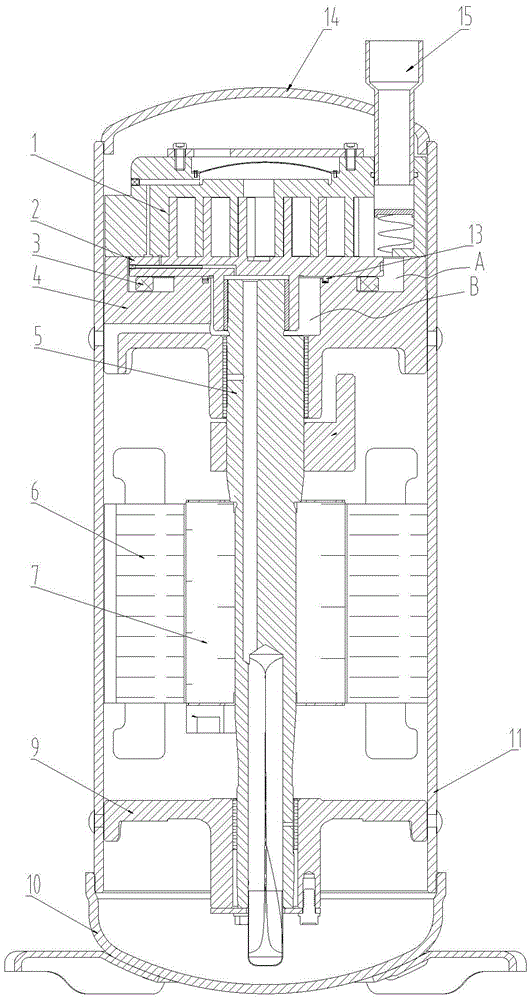

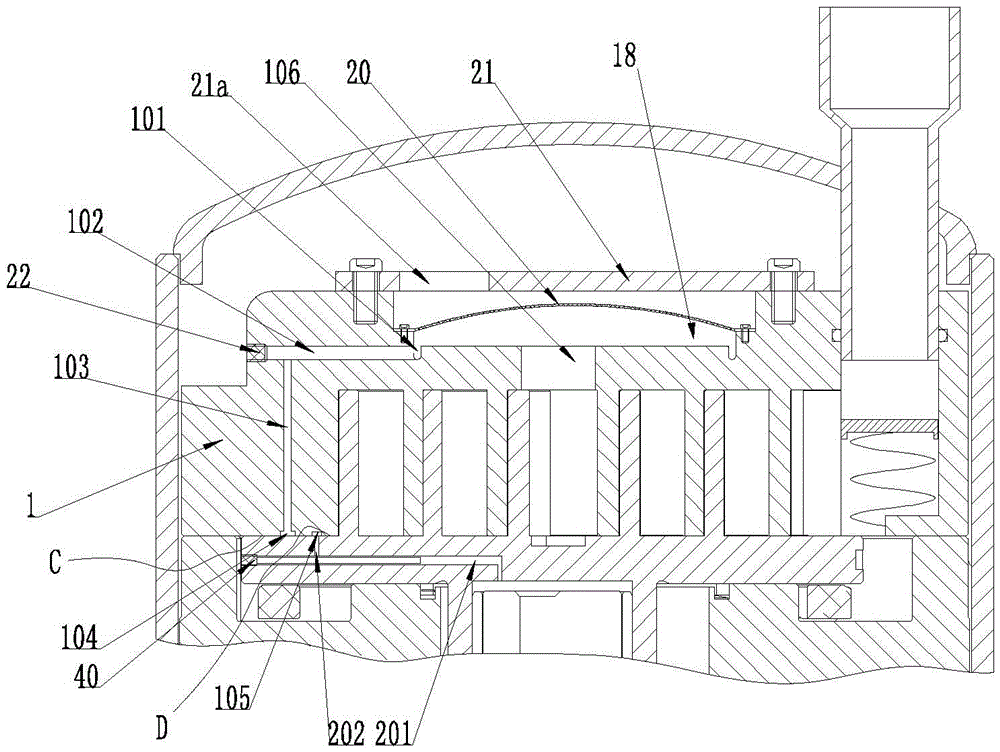

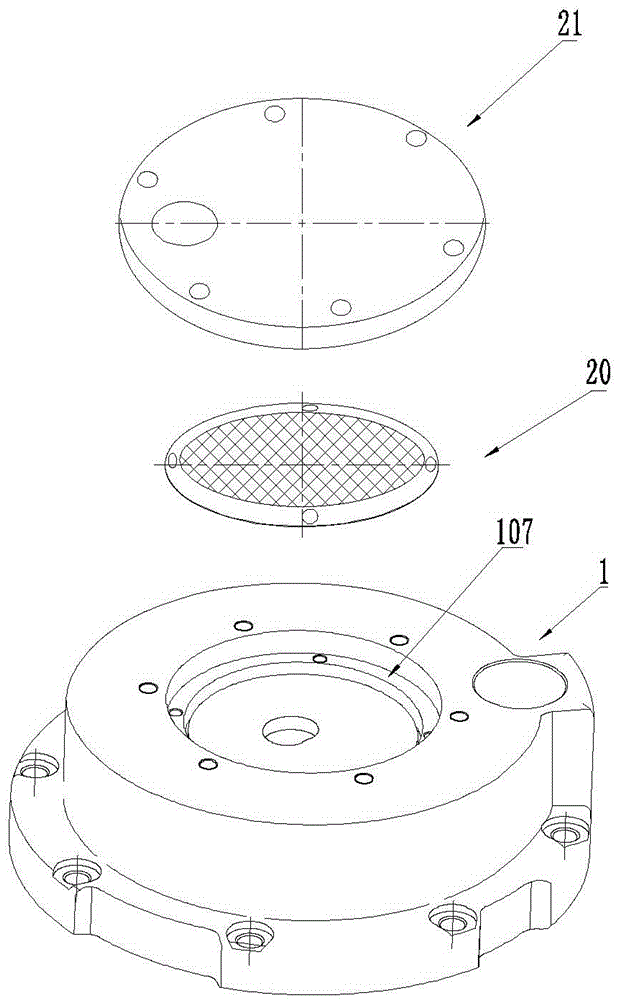

[0040] Such as Figure 1-4 As shown, the scroll compressor provided in this embodiment includes a fixed scroll 1 and a movable scroll 2; a compression chamber for compressing refrigerant is formed between the fixed scroll 1 and the movable scroll 2, and the fixed scroll The exhaust area of the disk 1 is provided with an exhaust buffer chamber 18 connected with the compression chamber, and an oil-gas separation device 20 is provided in the exhaust buffer chamber 18, and the refrigerant discharged from the compression chamber first enters the exhaust buffer chamber 18, and then passes through the oil-gas The separation device 20 separates oil and gas, and the separated lubricating oil falls to the bottom of the exhaust buffer chamber 18 . At the same time, at the end plate surface where the fixed scroll 1 and the movable scroll 2 are attached and located at the periphery of the compression chamber (the horizontal bonding of the fixed scroll 1 and the movable scroll 2 at the pe...

Embodiment 2

[0060] Such as Figure 5-7 As shown, the technical content of the second embodiment is the same as that of the first embodiment and will not be described repeatedly. The content disclosed in the first embodiment also belongs to the content disclosed in the second embodiment. The difference between the second embodiment and the first embodiment lies in the following points:

[0061] In this embodiment, the oil-gas separation device 20 is a filtering orifice plate, and the filtering orifice plate is a hemispherical orifice structure with the center protruding upward. The filtering orifice plate has a plurality of through holes 20a, which can be directly stamped from a thin metal plate. Certainly, the oil-gas separation device 20 may also be made of other materials having the function of oil-gas separation.

[0062] In this embodiment, the first oil groove 104 and the second oil groove 105 are respectively opened on the end plate surface of the movable scroll 2, which also have ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com