Rotating parts heat treatment automation device

A technology of automatic devices and rotating parts, applied in heat treatment furnaces, heat treatment equipment, quenching devices, etc., can solve problems such as unsatisfactory prices or functions, stone stuck between gears, and poor working environment, etc., to ensure quality and comprehensiveness Sexuality, energy saving, and fast mobile response effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

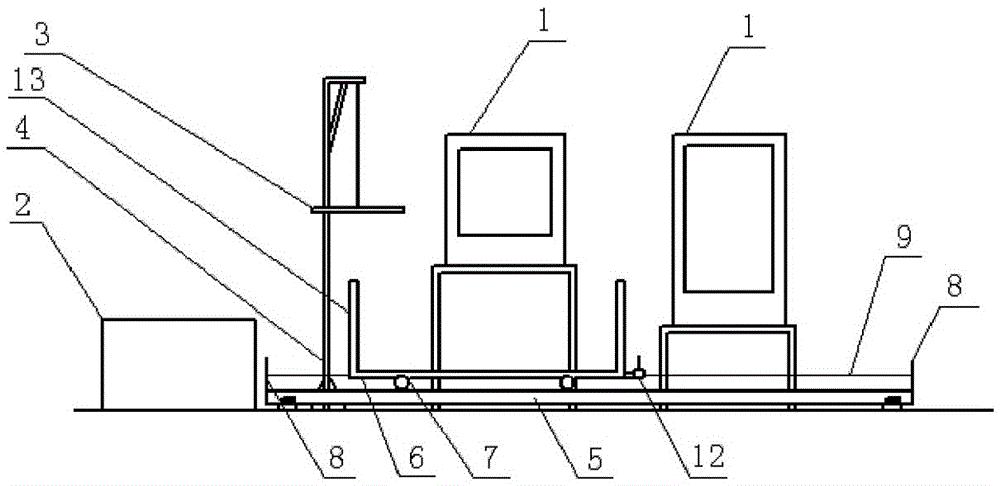

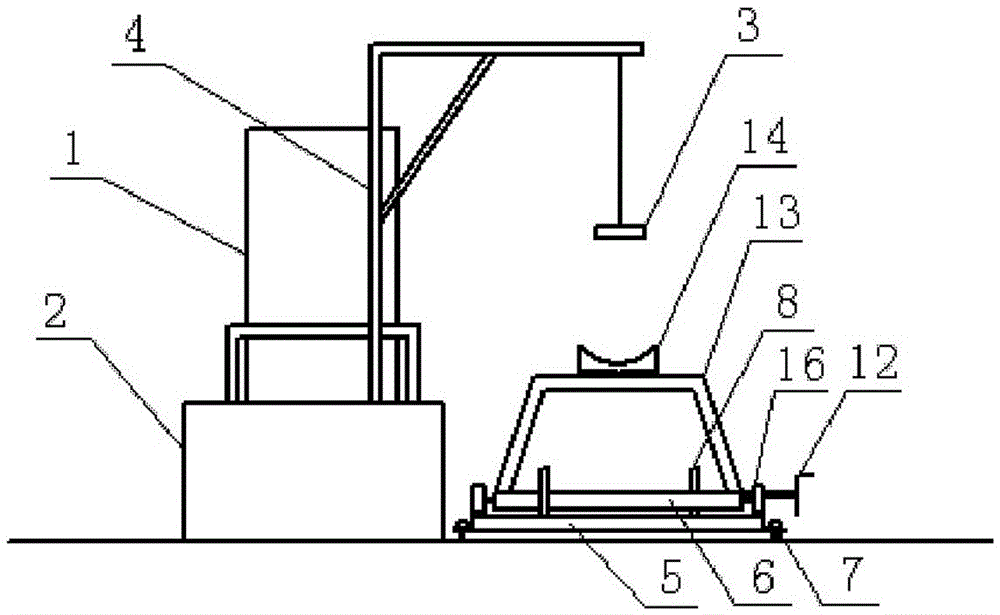

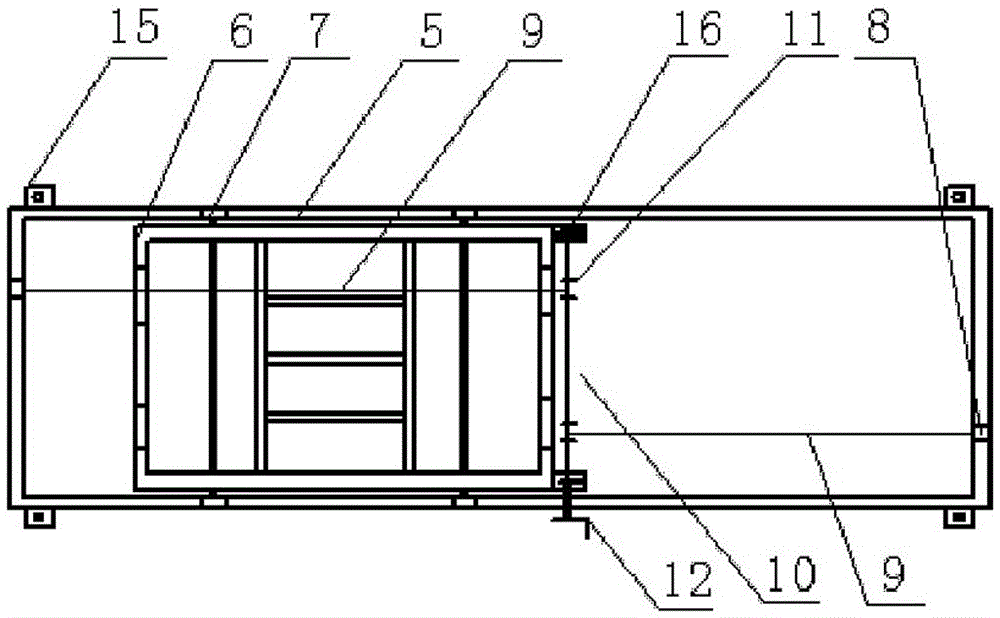

[0027] Example: see figure 1 , figure 2 and image 3 , in the picture, 1-full solid state induction heater, 2-water storage tank, 3-spray device, 4-spray bracket, 5-fixed bottom frame, 6-movable bracket, 7-pulley, 8-rope fixed plate , 9-rope, 10-rotating shaft, 11-rope limit plate, 12-driving device, 13-bracket, 14-fixed jig, 15-support plate, 16-bearing seat.

[0028] An automatic device for heat treatment of rotating parts, including an all-solid induction heater 1, water cooling equipment and a chassis fixing device, the all-solid induction heater 1 is connected to a power supply, and is arranged outside the water collection tank, and the water cooling equipment includes a water storage tank 2 and a spraying device 3. The water storage tank 2 is set outside the sump, and the spray device 3 is set above the sump through the spray bracket 4, and the bottom frame fixing device is set under the spray device 3, and in the sump, the bottom frame is fixed The device comprises ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com