Fermented honey and plum liquor and production method thereof

A production method and fermented technology, which is applied in the field of fermented honey plum wine and its production, can solve the problems of easy oxidative browning in the aging process, heavy bitterness and astringency of wine liquid, slow start of yeast fermentation, etc., and achieve good color protection effect , High clarification, speed up the effect of clarification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

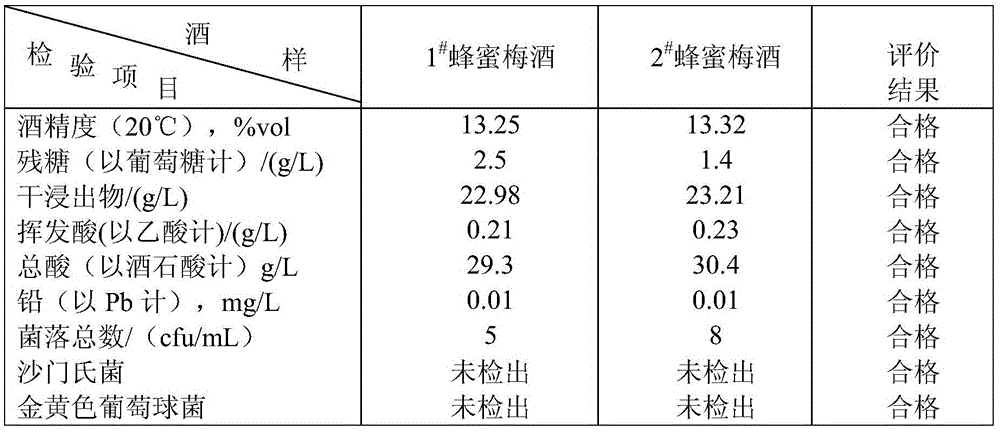

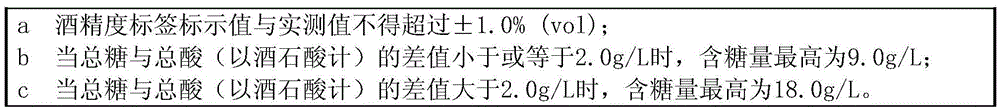

Embodiment 1

[0063] (1) Composite enzymatic hydrolysis and low-temperature fermentation of mixed bacteria are carried out simultaneously: after selection, cleaning, and green plums are crushed with a beater, they are moved into an impregnation tank, and pectinase EX is first added to the impregnation solution for enzymolysis. The enzymatic hydrolysis conditions are: Enzymolysis at 11.5°C for 6 hours; then add honey according to the mass ratio of greengage and honey at 4:1, and then add keratinase (Weifang Audier Import and Export Trade Co., Ltd.) for enzymolysis. Among them, pectinase EX was added at a final concentration of 38 mg / L in the enzymatic hydrolysis system, and keratinase was added at a final concentration of 42 mg / L in the enzymatic hydrolysis system. While adding keratinase, add wine yeast 71B (Shanghai Jietu Industry and Trade Co., Ltd., the addition amount is 0.3g / L) and Angel Wine High Active Dry Yeast RV100 (the addition amount is 0.3g / L) for fermentation, and the fermented...

Embodiment 2

[0079] (1) Composite enzymolysis and low-temperature fermentation of mixed bacteria are carried out simultaneously: after selection, cleaning, green plums are crushed with a beater, they are moved into an impregnation tank, and pectinase EX is first added to the impregnation solution for enzymolysis, enzymatic hydrolysis conditions Enzymolysis at 12.0°C for 5.5 hours; then add honey according to the mass ratio of greengage and honey at a ratio of 4:1, and then add keratinase for enzymolysis. Among them, pectinase EX was added at a final concentration of 43 mg / L in the enzymatic hydrolysis system, and keratinase was added at a final concentration of 47 mg / L in the enzymatic hydrolysis system. While adding keratinase, wine yeast 71B (addition amount: 0.25g / L) and Angel Wine High Active Dry Yeast RV100 (addition amount: 0.2g / L) were added for fermentation, and the fermentation condition was 14.2°C for 6 days; Then carry out clear juice separation by transfer tank, and add sugar (...

Embodiment 3

[0086] (1) Composite enzymatic hydrolysis and low-temperature fermentation of mixed bacteria are carried out simultaneously: after selection, cleaning, and green plums are crushed with a beater, they are moved into an impregnation tank, and pectinase EX is first added to the impregnation solution for enzymolysis. The enzymatic hydrolysis conditions are: Enzymolysis at 12.5°C for 5 hours; then add honey according to the mass ratio of greengage and honey at a ratio of 4:1, and then add keratinase for enzymolysis. Among them, pectinase EX was added at a final concentration of 48 mg / L in the enzymatic hydrolysis system, and keratinase was added at a final concentration of 52 mg / L in the enzymatic hydrolysis system. Add wine yeast 71B (addition amount: 0.35g / L) and Angel Wine High Active Dry Yeast RV100 (addition amount: 0.40g / L) at the same time as adding keratinase for fermentation, the fermentation condition is 15.2°C for 7 days; then Separation of clear juice by tank transfer, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com