Ion-conductive polymer electrolyte membrane, preparation method thereof and electrochromic glass

An electrochromic glass and electrolyte film technology, which is applied in instruments, optics, nonlinear optics, etc., can solve the problems of unmet requirements, low ionic conductivity of polymer electrolytes, etc., and achieves controllable process, simple production method, simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

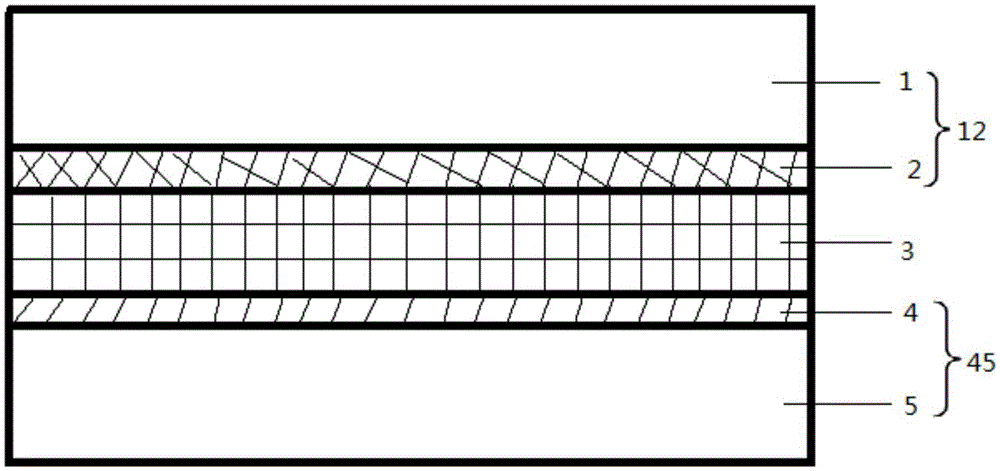

[0030] The embodiment of the present invention provides a method for preparing an ion-conducting polymer electrolyte film, the method comprising the following steps:

[0031] ① Blend polyethylene oxide (PEO) and polyvinylidene fluoride (PVDF) in proportion, add them to a container containing solvent dimethylacetamide (DMAC) and stir to dissolve, then add polycarbonate (PC), nano TiO 2 and lithium perchlorate (LiClO 4 ), stirred at a certain temperature for 2 to 5 hours to obtain the casting solution, and left to defoam for 12 to 15 hours under normal pressure, wherein the stirring temperature was 30 to 40°C;

[0032] ② Pour the film casting solution in ① on the polytetrafluoroethylene template, and spread it to form a film. Put the polytetrafluoroethylene template in an oven and dry it to form a film to obtain an ion-conducting polymer electrolyte film, an ion-conducting polymer electrolyte Films are doped polycarbonate (PC) and TiO 2 Polyethylene oxide (PEO) / polyvinylidene...

Embodiment 1

[0044] This embodiment provides a kind of preparation method of ion-conductive polymer electrolyte membrane, and this method comprises the following steps:

[0045] 1. Preparation of casting solution

[0046] Blend a total of 3.0g of PEO and PVDF with a mass ratio of 15:1, add to a container containing 35ml of DMAC solvent and stir to dissolve, then add LiClO accounting for 20wt% of the total amount of PEO+PVDF 4 , accounting for PEO+PVDF+LiClO 4 The total amount of 45wt% PC accounts for PEO+PVDF+LiClO 4 Total 4.5wt% nano-TiO 2 , stirred magnetically at a temperature of 30°C for 4h to obtain a casting solution, and left to defoam under normal pressure for 15h.

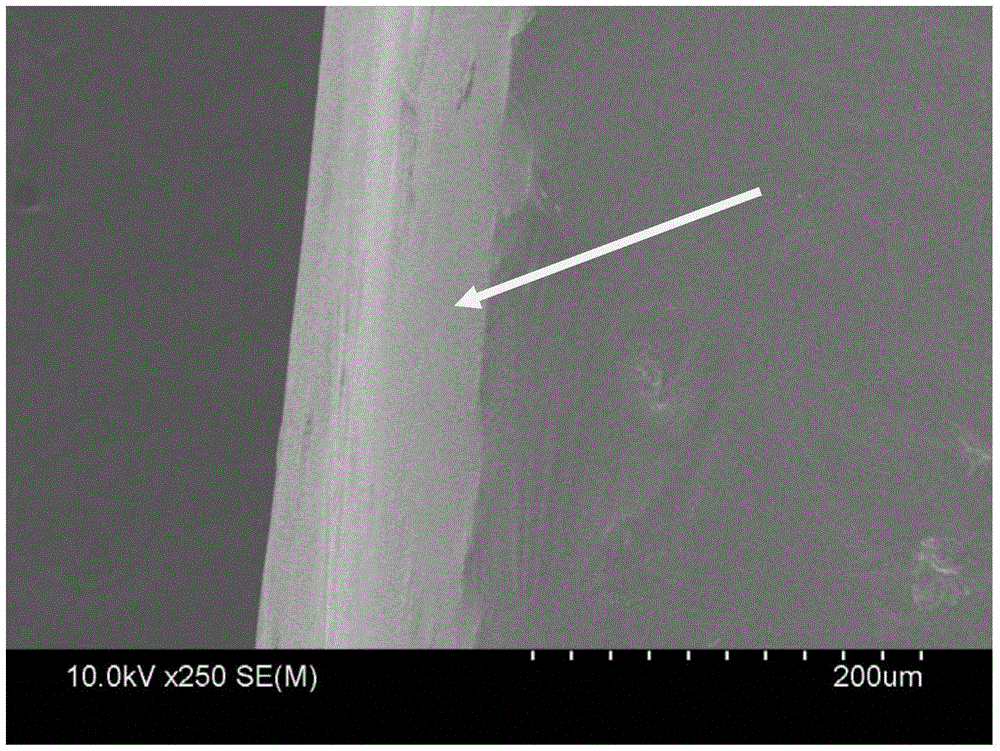

[0047] 2.PEO / PVDF / LiClO 4 / PC / TiO 2 Preparation of Ion Conductive Polymer Electrolyte Thin Film

[0048] Pour the above-mentioned casting solution on the polytetrafluoroethylene template, flow into a film, place the polytetrafluoroethylene template in a 40°C oven to dry to form a film, and obtain an ion-conductin...

Embodiment 2

[0066] This embodiment provides a kind of preparation method of ion-conductive polymer electrolyte membrane, and this method comprises the following steps:

[0067] 1. Preparation of casting solution

[0068] Blend a total of 2.5g of PEO and PVDF with a mass ratio of 19:1, add to a container containing 25ml of DMAC solvent and stir to dissolve, then add LiClO accounting for 18wt% of the total amount of PEO+PVDF 4 , accounting for PEO+PVDF+LiClO 4The total amount of 40wt% PC accounts for PEO+PVDF+LiClO 4 The total amount of 5wt% nano-TiO 2 , stirred magnetically at 35° C. for 3 hours to obtain a casting solution, and left to defoam under normal pressure for 14 hours.

[0069] 2.PEO / PVDF / LiClO 4 / PC / TiO 2 Preparation of Ion Conductive Polymer Electrolyte Thin Film

[0070] Pour the above-mentioned casting solution on the polytetrafluoroethylene template, flow into a film, place the polytetrafluoroethylene template in a 35°C oven and dry to form a film to obtain an ion-cond...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com