Fertilizer synergistic additive and preparation thereof

A technology of synergistic additive and fertilizer synergist, which is applied in fertilizer mixtures, fertilization devices, applications, etc., can solve the problems of limited effect of fertilizer nutrient release period, unable to meet the needs of one-time fertilization, and not outstanding fertilizer synergistic performance. , to achieve the effect of solving rapid absorption demand, improving utilization rate and increasing absorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1 Effect of synergistic compound fertilizer formed by applying the fertilizer synergistic additive on corn planting

[0025] experiment procedure:

[0026] (1) Preparation of fertilizer synergist

[0027] First, crush all the solid raw materials through 80 meshes, and set them aside;

[0028] Secondly, mix the polyglutamic acid fermentation broth (with 10% polyglutamic acid in the fermentation broth) and diatomaceous earth in a weight ratio of 1:1 for 10 minutes, dry at 80°C for 5 hours, and wait until the moisture content is lower than At 10%, stand by;

[0029] Finally, take 80 kg of the mixture of polyglutamic acid fermentation broth and diatomaceous earth with a moisture content of less than 10% and 15 kg of pulverized 80 mesh dicyandiamide, mix and stir for 10 minutes, and then add 1 kg of pulverized 80 mesh thiourea after mixing. And crushed 80 mesh n-butyl thiophosphoric triamide 4kg, and then stirred for 30 minutes, it is a solid dosage fertilizer synergist.

[0...

Embodiment 2

[0036] Example 2 Effect of synergistic urea formed by applying the fertilizer synergistic additive on eggplant planting

[0037] (1) Preparation of fertilizer synergist

[0038] Fertilizer synergistic additives are polyglutamic acid fermentation broth (3.5% polyglutamic acid in the fermentation broth) 85.5kg, thiourea 1.5kg, n-butyl thiophosphoric triamide 2kg, dicyandiamide 10kg, dehydrated sorbus 2kg of alcohol and fatty acids are mixed in a reactor, and stirred for 20 minutes at 80°C to form a liquid fertilizer synergist.

[0039] (2) Application method

[0040] The fertilizer synergistic additive obtained above and urea were sprayed on the surface of urea particles at a weight ratio of 6‰:1, and the fertilizer obtained after drying was used in the eggplant cultivation process. The growth period was 100 days. The urea was used as the control group. The base fertilizer is applied deeply in one time, and no top dressing in the mid-term.

[0041] (3) Test results

[0042] Experiments h...

Embodiment 3

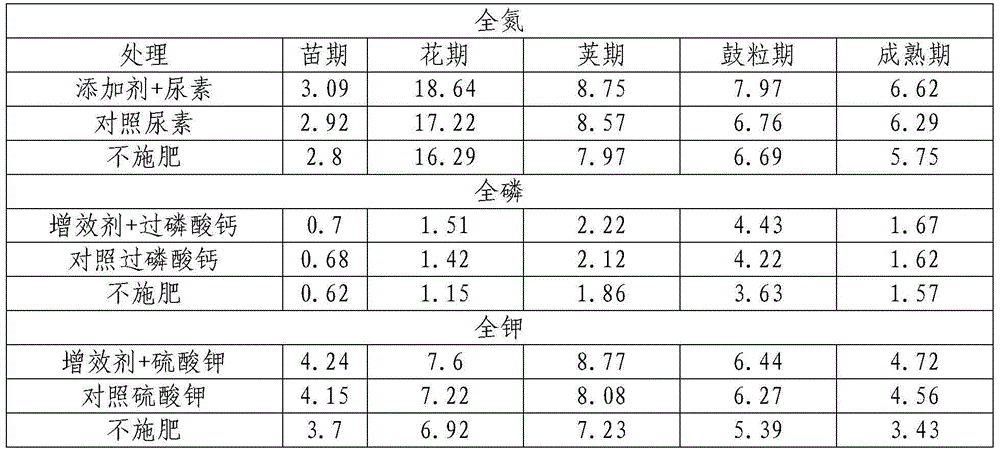

[0043] Example 3 The fertilizer synergist was used in a soybean pot experiment to study the effect on the total nitrogen, total phosphorus and total potassium of soybean plants.

[0044] (1) Preparation of fertilizer synergist

[0045] First, crush all the solid raw materials through 80 meshes, and set them aside;

[0046] Secondly, the polyglutamic acid fermentation broth (the polyglutamic acid in the fermentation broth contains 6%) and diatomaceous earth are mixed and stirred at a weight ratio of 1:1 for 15 minutes, and dried at 80°C for 6 hours, until the moisture content is lower than At 10%, stand by;

[0047] Finally, take 67 kg of the above-mentioned mixture of polyglutamic acid fermentation broth and diatomaceous earth with a moisture content of less than 10% and 25 kg of pulverized 80 mesh dicyandiamide, mix and stir for 10 minutes, and then add 1 kg of pulverized 80 mesh thiourea after mixing. And crushed 80 mesh n-butyl thiophosphoric triamide 7kg, and then stirred for 30 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com