Preparation method of polypropylene (PP)/nickel-coated glass fiber (NCGF) composite material

A glass fiber and composite material technology, which is applied in the field of preparation of conductive polymer composite materials, can solve the problems of reducing the conductive percolation value of composite materials, restricting applications, and reducing the mechanical properties of materials, and achieves improved crystallinity, efficient construction, and strength. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

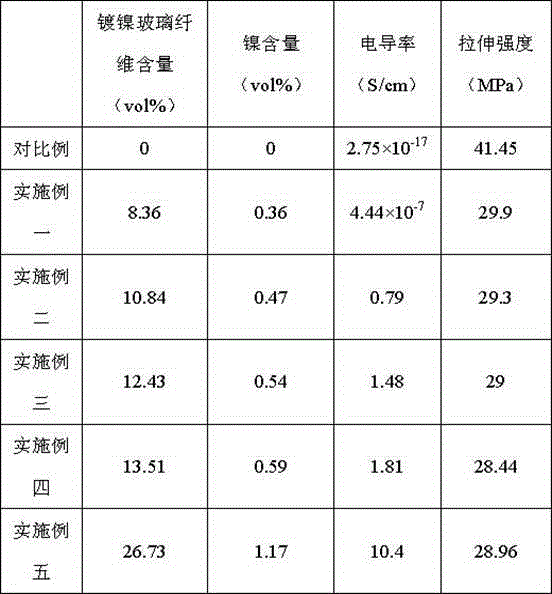

Embodiment 1

[0023] Raise the temperature of the torque rheometer to 200 °C, add 30 g of homopolypropylene to it, and banbury for 5 minutes at a speed of 60 rpm to fully melt the homopolypropylene;

[0024] Add 0.06 g of sorbitol-based nucleating agent DBS to the torque rheometer, the quality of sorbitol-based nucleating agent DBS is 0.2% of the homopolymer polypropylene mass, and knead for 5 min to make the two evenly mixed;

[0025] Add nickel-plated glass fiber wherein again, make the volume ratio of polypropylene and nickel-plated glass fiber be 91.64:8.36, knead for 8 min, obtain the evenly dispersed mixture;

[0026] The mixture was hot-pressed at 190 °C and 10 MPa to obtain a polypropylene / nickel-plated glass fiber composite material with high electrical conductivity and strength.

Embodiment 2

[0028] Raise the temperature of the torque rheometer to 200 °C, add 50 g of homopolypropylene to it, and banbury for 6 min at a speed of 60 rpm to fully melt the homopolypropylene;

[0029] Add 0.1 g of sorbitol-based nucleating agent DBS to the torque rheometer, the quality of sorbitol-based nucleating agent DBS is 0.2% of the mass of homopolypropylene, and knead for 8 min to make the two evenly mixed;

[0030] Add nickel-plated glass fiber wherein again, make the volume ratio of polypropylene and nickel-plated glass fiber be 89.16:10.84, knead for 10 min, obtain the evenly dispersed mixture;

[0031] The mixture was hot-pressed at 190 °C and 15 MPa to obtain a polypropylene / nickel-plated glass fiber composite material with high electrical conductivity and strength.

Embodiment 3

[0033] Raise the temperature of the torque rheometer to 200 °C, add 40 g of homopolypropylene to it, and banbury for 7 minutes at a speed of 60 rpm to fully melt the homopolypropylene;

[0034] Add 0.08 g of sorbitol-based nucleating agent DBS to the torque rheometer, the quality of sorbitol-based nucleating agent DBS is 0.2% of the homopolymer polypropylene mass, and knead for 5 min to make the two evenly mixed;

[0035] Add nickel-plated glass fiber to it again, make the volume ratio of polypropylene and nickel-plated glass fiber be 87.77:12.23, knead for 10 min, obtain the evenly dispersed mixture;

[0036] The resulting mixture was hot-pressed at 190 °C and 12 MPa to obtain a polypropylene / nickel-plated glass fiber composite material with high electrical conductivity and strength.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com