Light grouting material for grouting treatment of highway goaf and preparation method of light grouting material

A technology of grouting materials and gobs, applied in applications, household utensils, ceramic products, etc., can solve the problems of adverse effects on the stability of gobs, potential safety hazards in goaf stability, and high water content of grouting slurry, and achieve The effect of shortening the grouting construction period, good social and economic benefits, and reducing the amount of grouting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

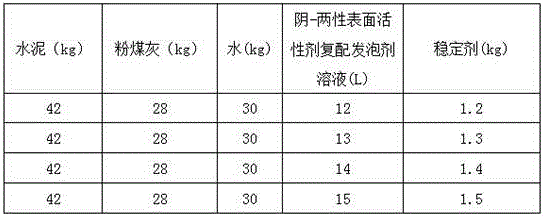

[0027] The lightweight grouting material used in the grouting treatment of highway mined-out area is to mix cement, fly ash and water to prepare cement fly ash slurry, and then add an anion-amphoteric surfactant compound foaming agent A lightweight grouting material obtained by solution mixing. Concrete preparation method comprises the following steps:

[0028] Step 1: mixing cement, fly ash and water according to the mass ratio of 21:14:15, stirring evenly to obtain cement fly ash slurry;

[0029] Step 2: Add the anion-zwitterionic surfactant into the water, stir evenly to obtain a surfactant solution with a concentration of 0.60-0.64g / 100mL, and then add the mass ratio of the anion-zwitterionic surfactant to the surfactant solution Be the stabilizing agent of 5:32, obtain anion-amphoteric surfactant compound whipping agent solution;

[0030] Step 3: in the cement fly ash slurry that step 1 obtains, add the anion-amphoteric surfactant compound blowing agent solution that st...

Embodiment 1

[0039] In the anionic-zwitterionic surfactant, the mass ratio of the anionic surfactant to the amphoteric surfactant is 8:1.

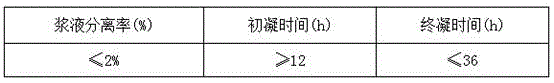

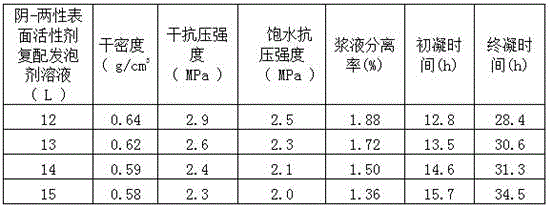

[0040] Verified by the use of the test road, the lightweight grouting material used in this implementation example has low concretion density and high compressive strength, meeting the specification requirements. The dry density of stone body is about 0.6g / cm 3 , Dry compressive strength and saturated compressive strength ≥ 2.0MPa. See the table below for specific technical indicators:

[0041]

Embodiment 2

[0043] In the anionic-zwitterionic surfactant, the mass ratio of the anionic surfactant to the amphoteric surfactant is 6:1.

[0044] Verified by the use of the test road, the lightweight grouting material used in this implementation example has low concretion density and high compressive strength, meeting the specification requirements. The dry density of stone body is about 0.6g / cm 3 , Dry compressive strength and saturated compressive strength ≥ 1.6MPa. See the table below for specific technical indicators:

[0045]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dry density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com