Method and device for treating circulating spray liquid discharged by printing and dyeing wastewater deodorization system

A technology for circulating spraying and printing and dyeing wastewater, applied in textile industry wastewater treatment, multi-stage water treatment, water/sewage treatment, etc., can solve problems such as anaerobic and aerobic system death, sewage treatment system impact, etc., to reduce pollution content, reduce hazards, and maintain normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

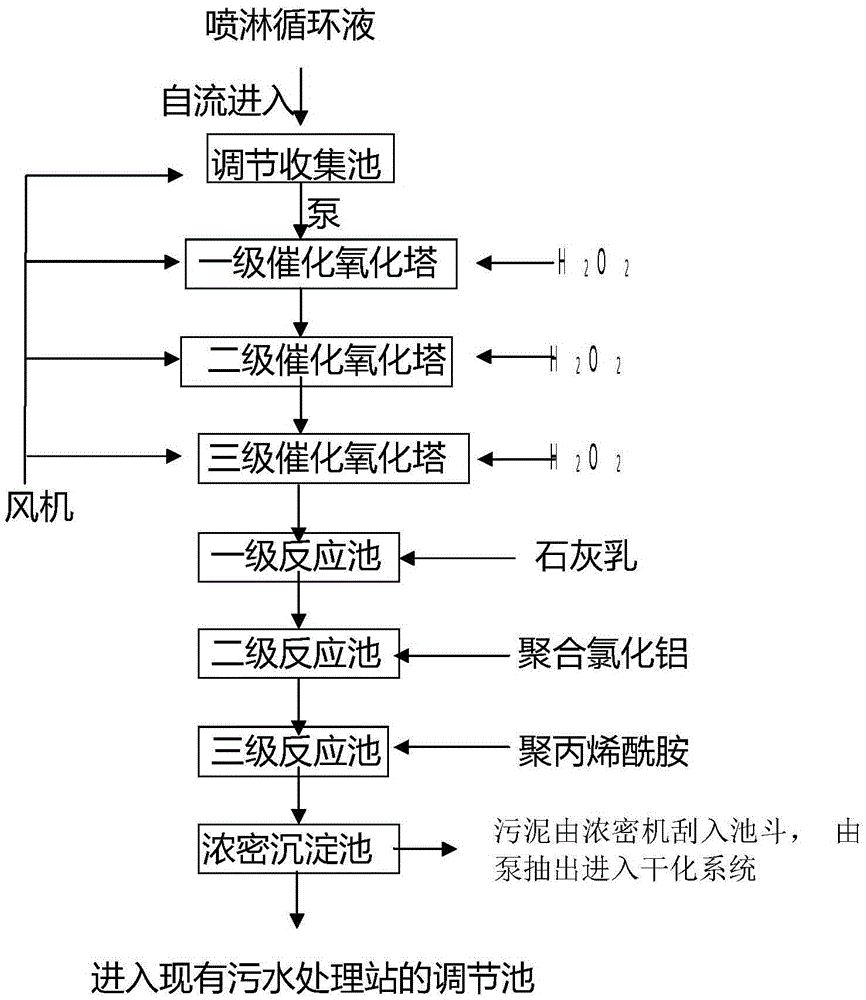

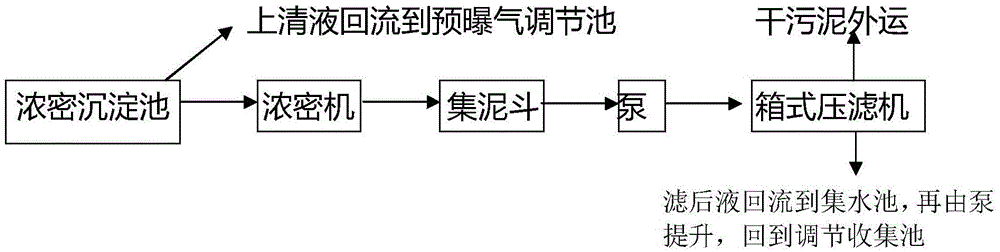

Embodiment 1

[0030] The above-mentioned device is used in the upgrading and upgrading of a textile printing and dyeing sewage treatment plant for the technical research of sewage treatment. The influent water quality of the printing and dyeing wastewater treatment plant is: COD cr 6000-8000mg / L, sulfide 1200-2200mg / L, pH8.5-10.0. The hydraulic retention time of the control adjustment tank is 20h; the residence time of the three-stage catalytic oxidation tower is 0.25h, and the concentration of hydrogen peroxide added by the hydrogen peroxide dosing device is 27.50%, which is added in three stages; The residence time of the reaction tank is 0.5h, 0.5h and 0.45h respectively; the surface load of the dense sedimentation tank is 1.80m 3 / m 2 h, the residence time is 3.5h. After the treatment of the process proposed by the present invention, the water quality of the effluent reaches: COD cr <5000mg / L, sulfide <2mg / L, pH6.5~9.0. The annual reduction of the main pollutant sulfide by the inve...

Embodiment 2

[0032] The above-mentioned device is applied to the technical research of denim yarn sizing wastewater treatment in a sizing and dyeing factory. The influent water quality of the printing and dyeing wastewater treatment plant is: COD cr 4800-6300mg / L, sulfide 1200-1500mg / L, pH7.5-8.5. The hydraulic retention time of the control adjustment tank is 18h; the residence time of the three-stage catalytic oxidation tower is 0.20h, and the concentration of hydrogen peroxide added by the hydrogen peroxide dosing device is 27.50%, which is added in three stages; The residence time of the reaction tank is 0.42h, 0.42h and 0.4h respectively; the surface load of the dense sedimentation tank is 1.85m 3 / m 2h, the residence time is 3.2h. After the treatment of the process proposed by the present invention, the water quality of the effluent reaches: COD cr <4000mg / L, sulfide <2mg / L, pH6.5~8.5. The annual reduction of the main pollutant sulfide by the invented process is 313.7 tons / year.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com