Electromagnetic briquetting machine

A briquetting machine, electromagnetic technology, applied in punching machines, presses, presses using rotating pressure components, etc., can solve problems such as work efficiency limitations, long reciprocating strokes of hydraulic rods, bursting, etc., to reduce the occupied space, mechanical The overall compactness and the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

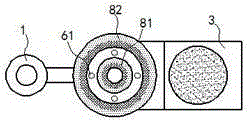

[0014] exist figure 1 In the illustrated embodiment, the electromagnetic briquetting machine includes a feed end 1, a press bin 2 and a conveyor belt 3; the feed end 1 is installed on the side wall of the press bin 2; The bottom side wall of the loading bin 2 is provided with a discharge end 4, and the discharge end 4 is engaged with the conveyor belt 3; A discharge plate 21, the discharge plate 21 is controlled by the mechanical arm 211 to reciprocate; the upper half of the inner wall of the press-loaded warehouse 2 is provided with a pressurized thread; A pressurizing screw 5, the pressurizing screw 5 is matched with the pressurizing thread; the material hardness of the pressurizing screw 5 is less than the material hardness of the sidewall of the press-fitting bin 2; at the bottom of the pressurizing screw 5 A pressure piece 51 is installed, the pressure piece 51 is coaxial with the pressure screw 5, and the pressure piece 51 can rotate freely relative to the pressure scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com