Flexible circuit board pressing device and rapid pressing machine

A flexible circuit board and lamination device technology, applied in the direction of lamination device, lamination, layered products, etc., can solve the problems of affecting lamination quality, uneven force, reducing lamination accuracy, etc., to increase processing accuracy And the effect of stability, increased force area, and guarantee of pressing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

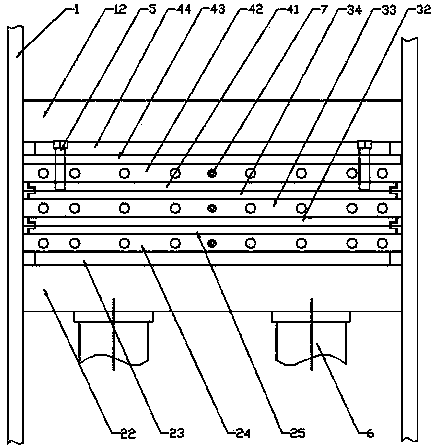

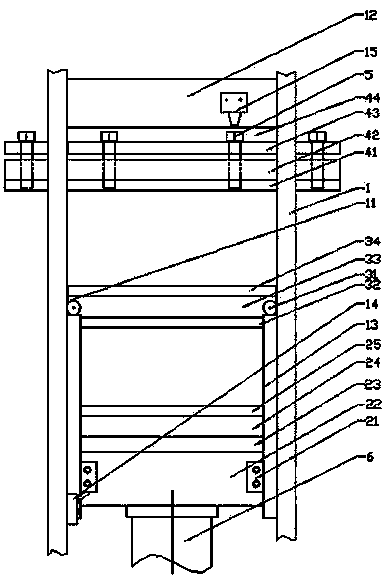

[0021] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, in this embodiment, the flexible circuit board pressing device of the present invention includes a frame 1, a lower pressing plate 2, an intermediate plate 3, and an upper pressing plate 4, and the number of the intermediate plates 3 can be set to one or more. In an embodiment, the number of the intermediate board is set to one. Guide wheels 31 are connected around the middle plate 3 , and the guide wheels 31 are rollingly connected with the guide plane 11 arranged on the inner wall of the frame 1 . The upper pressing plate 4 is balancedly arranged on the top of the frame 1 by several bolts 5, the lower pressing plate 2 is provided with a guide slider 21, and the lower part of the inner wall of the frame 1 is provided with a guide rail 13, and the guide slider 21 is slidingly matched with the guide rail 13, the guide plane 11 stops at the upper end surface of the guide rail 13, and the upper end surface o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com