Rocker for articulated industrial robots and articulated industrial robots

An industrial robot and joint-type technology, which is applied in the direction of manipulators, manufacturing tools, and program-controlled manipulators, can solve the problems of reducing casting performance, large thickness changes, and increasing the difficulty of demoulding, so as to improve casting and processing performance and enhance Strength and rigidity performance, effect of reducing manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

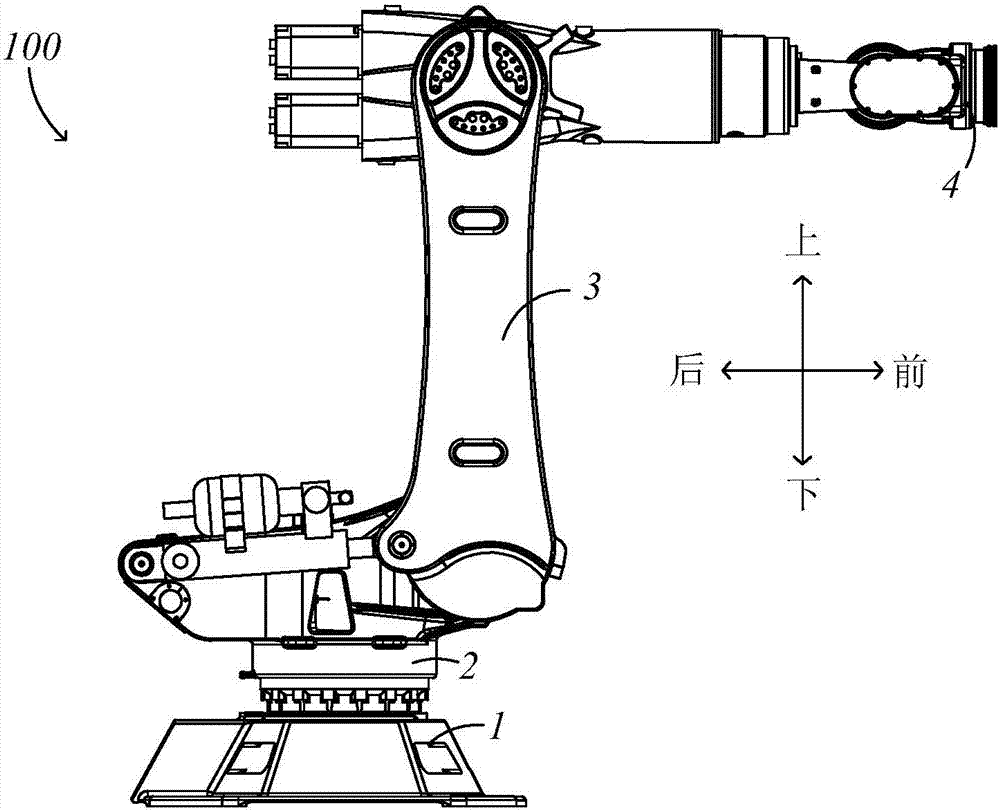

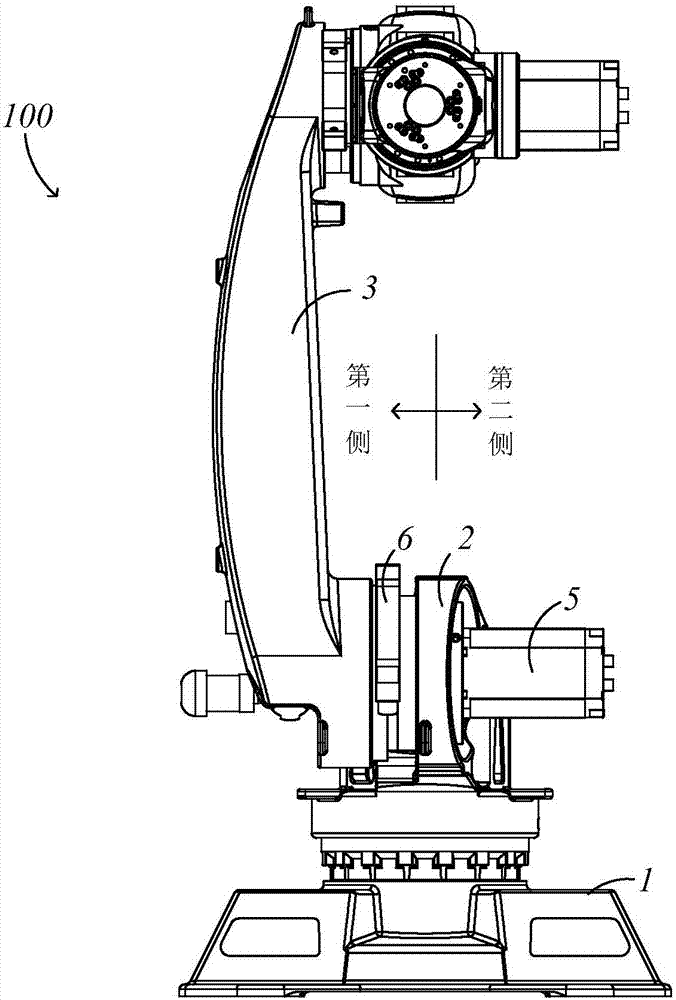

[0031] Such as Figure 1~Figure 2 As shown, the articulated industrial robot 100 includes a base 1, a rocker 2 (or waist part) connecting the first joint and the second joint of the articulated industrial robot 100, a connecting rod 3 (or a big arm), and a Structures such as the operating hand 4 on the connecting rod 3. In order to clearly express the position and direction described in this application, taking the articulated industrial robot 100 as a reference, one end of the upper arm with the operating hand 4 is the front, and the opposite end is the rear end; and the upper arm is located on the upper part of the base 1 .

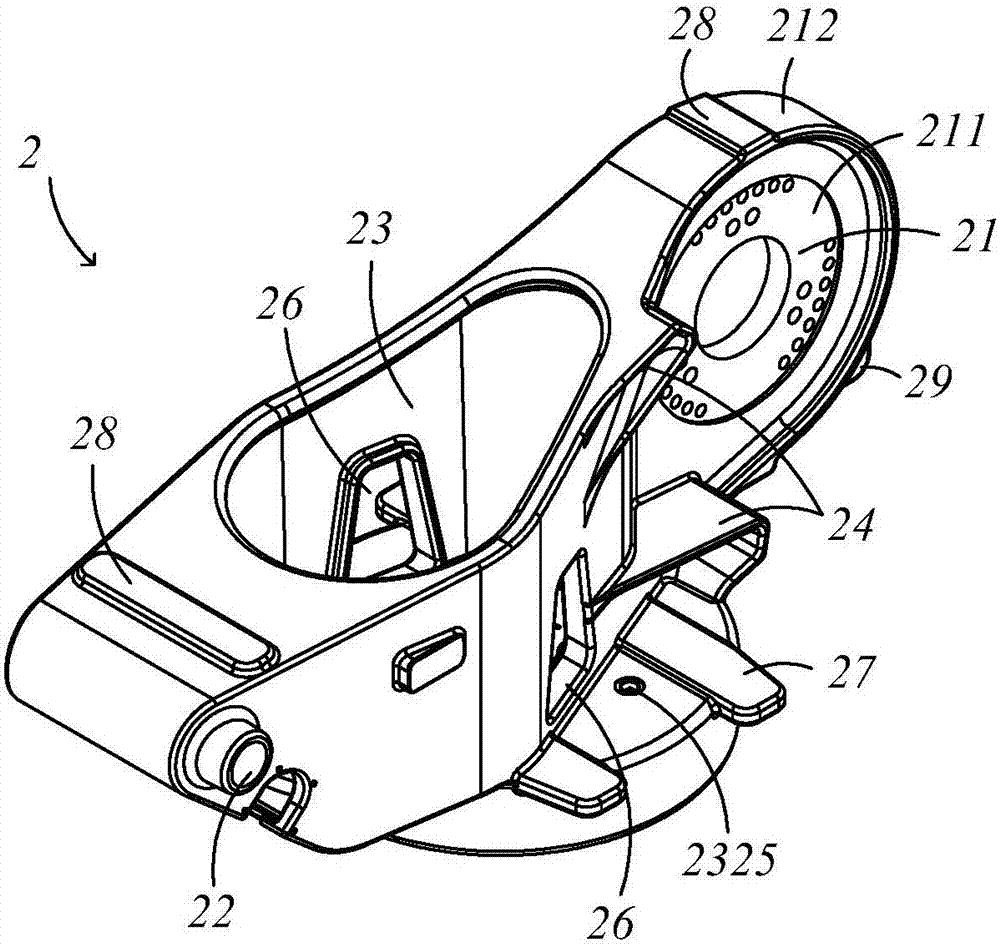

[0032] One side of the rocker 2 of the body structure of the articulated industrial robot 100 needs to be connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com