Feeding device

A technology of feeding device and lifting device, which is applied in the field of high-speed stamping, can solve the problems of long vertical distance, damage to the receiving tray, and loud noise in the workshop, and achieve the effects of low noise, reduced bearing capacity, and less damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

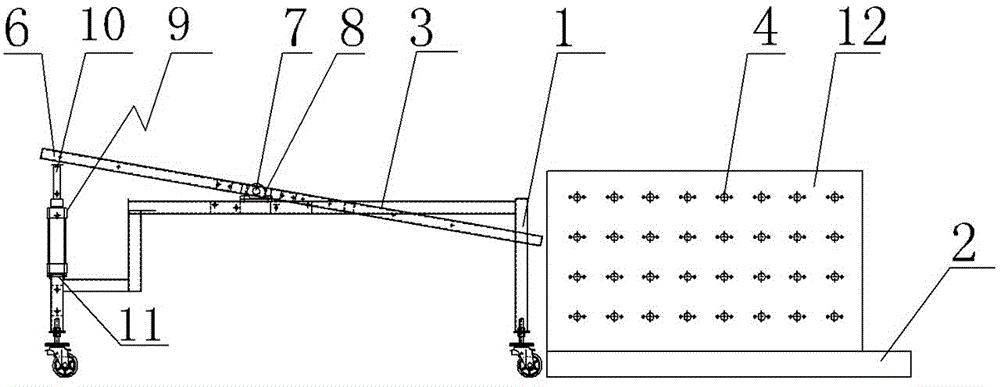

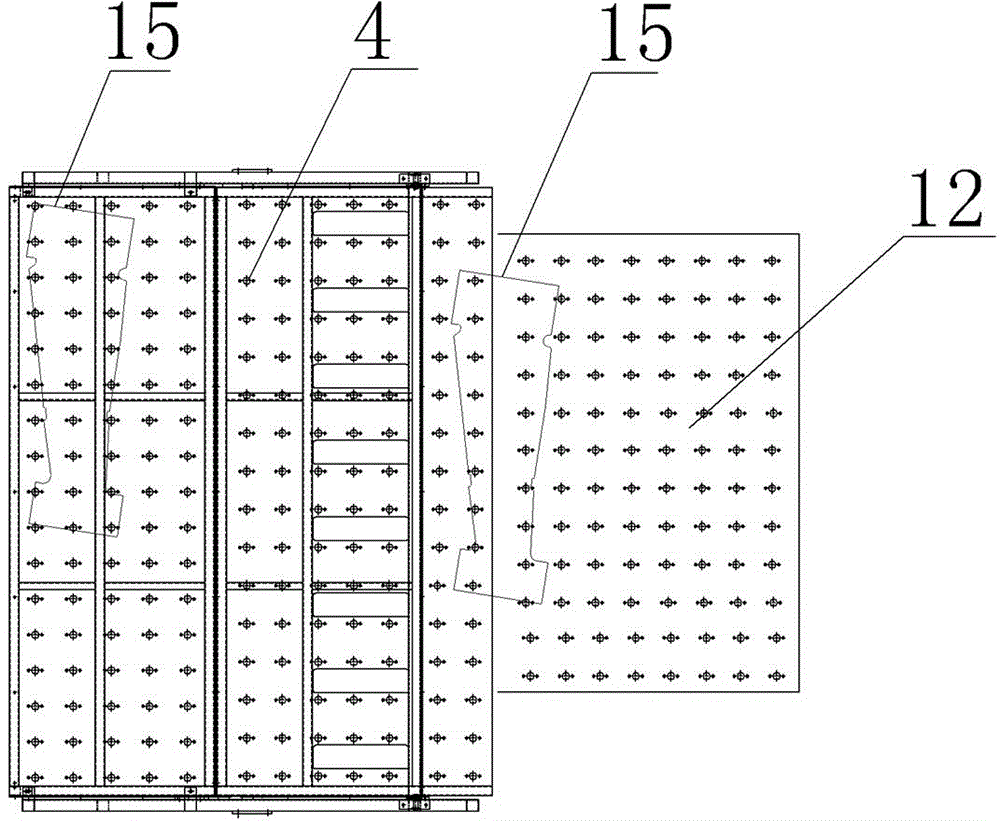

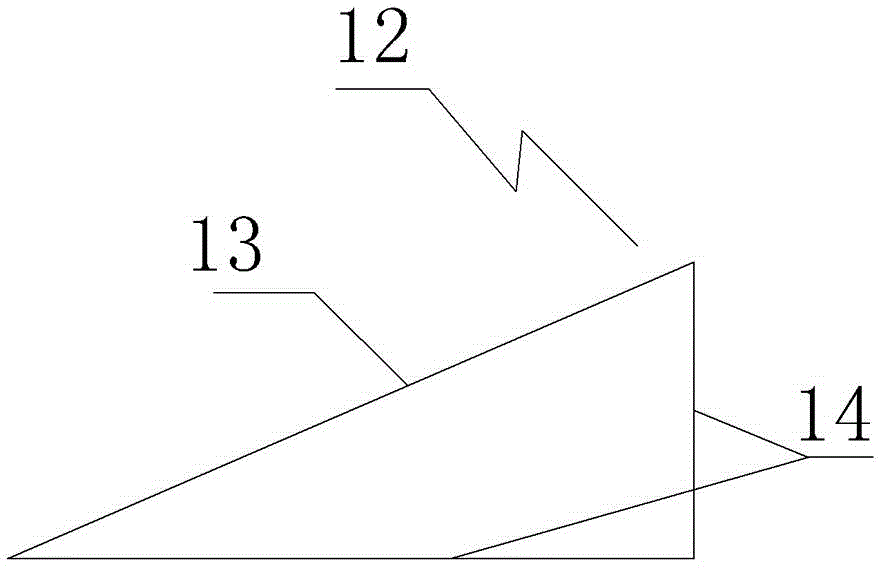

[0017] See figure 1 , figure 2 , image 3 As shown, the present invention comprises a frame 1, a receiving tray 2, an inclined slide table 3, the surface of the inclined slide table 3 is provided with universal rollers 4, the middle part of the inclined slide table 3 is movably connected to the frame 1, and the inclined slide table 3 At least one end 6 is provided with a lifting device (such as figure 1 shown), the lifting device can also be arranged at the other end of the inclined slide table 3 (with figure 1 The middle is different, refers to the lower end of the inclined slide), and lifting devices can also be installed at both ends of the inclined slide as required. The middle part of the inclined slide table 3 is connected to the rotary shaft 7, and the rotary shaft 7 is installed on the frame 1 through the bearing seat 8; as figure 1 As shown, the preferred embodiment of the present embodiment is the cylinder 9 as the lifting device, one end of the piston rod 10 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com