Screw oiling device

A screw and oil hole technology, applied in the field of screw oiling devices, can solve the problems that screws are susceptible to corrosion and salinization, difficult to apply evenly, time-consuming and labor-intensive, etc., to achieve the effect of convenient storage and arrangement, ensuring flow area, and ensuring normal flow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

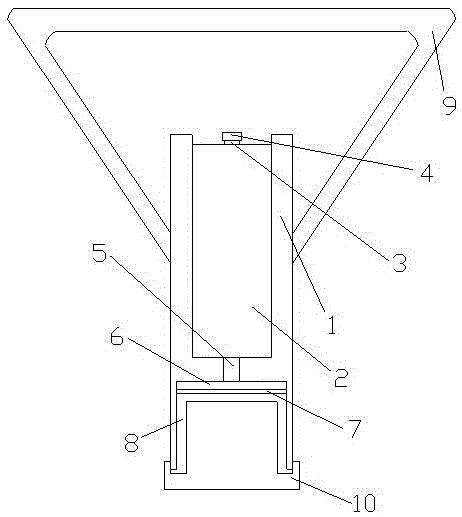

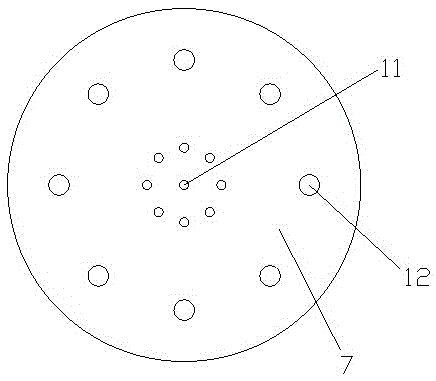

[0016] Such as figure 1 and figure 2 An embodiment of a screw lubricating device of the present invention is shown, the screw lubricating device includes a main body 1, an oil storage tank 2 is arranged inside the main body 1, and an oil inlet 3 and an oil guide pipe are connected to the oil storage tank 2 5. The oil inlet 3 is connected with the cover 4, the oil guide pipe 5 is connected with the buffer space 6, the oil guide pipe 5 and the buffer space 6 are evenly filled with cotton, the buffer space 6 is connected with the oil diffuser 7, the oil diffuser 7 is provided with a first oil hole 11 and a second oil hole 12, the bottom of the oil spreading plate 7 is connected with an oil spreading layer 8, the material of the oil spreading layer 8 is sponge, the main body 1 is connected with a bottom cover 10, the cover 4 and the bottom The cover 10 is detachable, the main body 1 is connected with a handle 9 , and the diameter of the first oil hole 11 is smaller than that of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com