Printing and dyeing raw material mixing equipment based on synchronous mixing treatment

A mixing equipment and mixing treatment technology, applied in mixers, mixers with rotating containers, chemical/physical processes, etc., can solve problems such as difficult uniform mixing, color uniformity of printing and dyeing molding products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

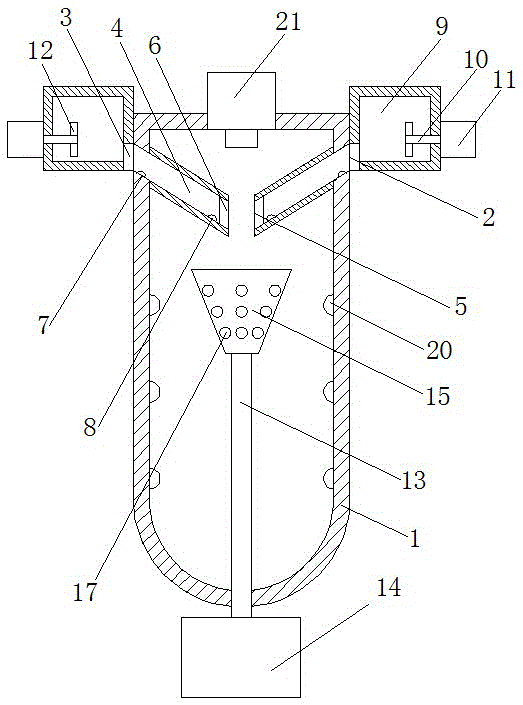

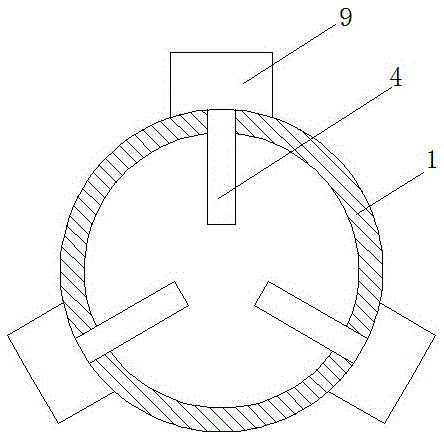

[0023] Such as figure 1 and figure 2 A kind of printing and dyeing raw material mixing equipment based on synchronous mixing treatment is shown, which includes a mixing cylinder 1, and three feeding ports 2 extending to the inside are arranged on the mixing cylinder 1, and the three feeding ports 2 It is rotationally symmetrical about the axis of the mixing cylinder 1, and a first control valve 3 is respectively arranged inside each feed port 2; Pipe 4, a plurality of feed pipes 4 are rotationally symmetrical about the axis of the mixing cylinder 1, and they all extend obliquely downward along the feed port 2, and each feed pipe 4 is away from the end of the side of the mixing cylinder 1 A metering port 5 is arranged at the top of the metering port 5, and a second control valve 6 is arranged at the corresponding position of the metering port 5; among the feed pipeline 4, a first flow meter 7 is arranged at a corresponding position on one side of the feed port 2, and the inle...

Embodiment 2

[0031] As an improvement of the present invention, such as figure 1 As shown, in each feeding box body 9, two feeding stirring blades 12 opposite to each other are arranged on the feeding stirring shaft 10, and the two feeding stirring blades 12 are turned 40 to 60° opposite to each other, which Through the structural setting of the feeding stirring blade, it can form a liquid flow that moves axially along the stirring shaft, so that the primary color dye in the feeding box can form a liquid flow moving toward the feeding port, and the feeding efficiency can be significantly improved. improve.

[0032] The remaining features and advantages of this embodiment are the same as those of Embodiment 1.

Embodiment 3

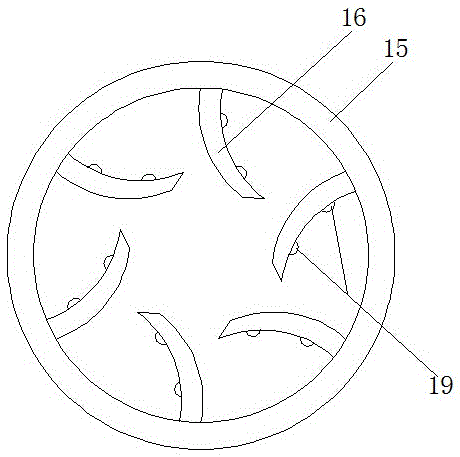

[0034] As an improvement of the present invention, such as Figure 4 As shown, in the outer wall of the stirring tank 15 , the upper end of each discharge hole 17 is provided with a deflector 18 , and the deflector 18 adopts an arc structure bent toward the upper end of the mixing cylinder 1 . With the above technical scheme, it can ensure that the dye thrown from the discharge hole moves towards the bottom of the mixing cylinder under the action of the deflector, so as to prevent the dye from being thrown onto the inner wall of the mixing cylinder, resulting in waste of raw materials and waste of cleaning. inconvenient.

[0035] The remaining features and advantages of this embodiment are the same as those of Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com