Preparation method of forward osmosis membrane modified with oxidized graphene

A graphene modification, forward osmosis membrane technology, applied in chemical instruments and methods, semi-permeable membrane separation, membrane technology and other directions, can solve the problems of large internal concentration polarization, unstable flux, low strength, etc. Simple process, simple film forming process, easy to achieve effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

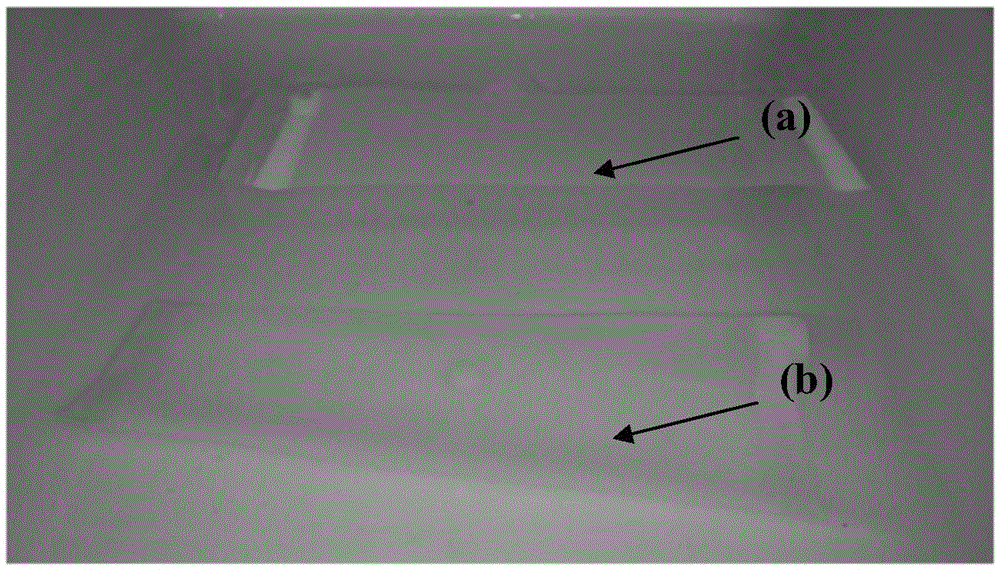

Image

Examples

Embodiment 1

[0051] Uniformly disperse 0.1% graphene oxide in 35% DMAC for 1 hour, then add 35% 1,4-dioxane, 13% acetone, additive 3.8% methanol, and 3.1% lactic acid to the dispersion at one time , and finally add 10% high molecular polymer cellulose triacetate (CTA). Stir in a constant temperature water bath at 50°C until completely dissolved, then put it in a vacuum drying oven at 50°C (vacuum degree: 0.08MPa) and let stand for defoaming for more than 12h. Afterwards, in an environment with a temperature of 20°C and a relative humidity of 70%, the film was scraped with a manual film scraper using the phase inversion method, and the support layer was a 150-mesh polyester screen. After the scraped film was volatilized in the air for 30 seconds, it was placed in Place in a coagulation bath of deionized water at 20°C for 4 hours. The membrane is separated from the glass plate, and the newly formed membrane is fully soaked in pure water for 48 hours to obtain a supported graphene oxide flat...

Embodiment 2

[0054] Uniformly disperse 0.1% graphene oxide in 32% DMAC for 1 hour, then add 32% 1,4-dioxane, 12.4% acetone, additive 6% methanol, and 4.5% lactic acid to the dispersion at one time , and finally add 13% polymer cellulose acetate (CA). Stir in a constant temperature water bath at 60°C until completely dissolved, then put it into a vacuum drying oven at 60°C (vacuum degree is 0.08MPa) and let stand for defoaming for more than 12h. Afterwards, in an environment with a temperature of 20°C and a relative humidity of 70%, the film was scraped with a manual film scraper using the phase inversion method, and the support layer was a 150-mesh polyester screen. After the scraped film was volatilized in the air for 30 seconds, it was placed in Place in a coagulation bath of deionized water at 20°C for 4 hours. The membrane is separated from the glass plate, and the newly formed membrane is fully soaked in pure water for 48 hours to obtain a supported graphene oxide flat forward osmosi...

Embodiment 3

[0057] Uniformly disperse 0.1% graphene oxide in 32% DMAC for 1 hour, then add 32% 1,4-dioxane, 12.4% acetone, additive 6% methanol, and 4.5% lactic acid to the dispersion at one time , finally add 6.5% high molecular polymer cellulose triacetate (CTA) and 6.5% high molecular polymer cellulose acetate (CA) and stir in a constant temperature water bath at 60°C until completely dissolved, then put it in 60°C In a vacuum drying oven (vacuum degree of 0.08MPa) stand for degassing for more than 12h. Afterwards, in an environment with a temperature of 20°C and a relative humidity of 70%, the film was scraped with a manual film scraper using the phase inversion method, and the support layer was a 250-mesh polyester screen. After the scraped film was volatilized in the air for 30 seconds, it was placed in Place in a coagulation bath of deionized water at 20°C for 4 hours. The membrane is separated from the glass plate, and the newly formed membrane is fully soaked in pure water for 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Contact angle | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com