A quick unloading safety valve

A safety valve and fast technology, applied in the field of hydraulic components, can solve problems such as poor reliability, blocked orifice, and high requirements for oil circuit cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

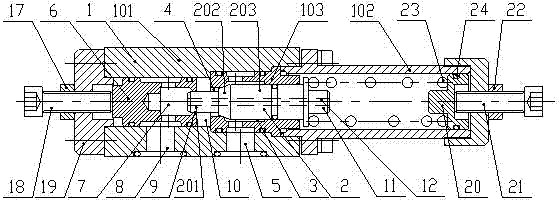

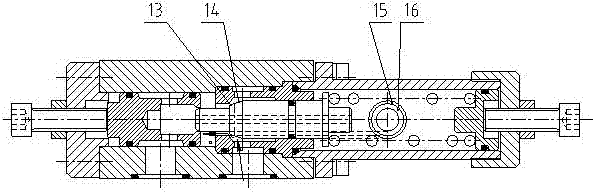

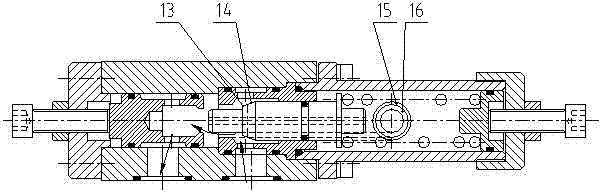

[0031] Below in conjunction with accompanying drawing, this technology is further described:

[0032] see figure 1 The quick unloading safety valve shown includes a valve body 1 and a valve core 2 that is moved and arranged in the valve body 1; the valve body 1 includes a main valve body 101 and a spring box 102 fixedly connected to the right end of the main valve body 101; the integral The spool 2 from left to right is a throttle end 201 with a smaller diameter, a tapered transition section 202, and a main body 203 with a larger diameter; the right end of the main valve body 101 is provided with a fixed sleeve 103 with a stepped hole; the fixed sleeve 103 is provided with a spool 2 for movement; the diameter of the left hole 4 with a smaller aperture of the fixed sleeve is larger than the diameter of the throttle end 201 of the spool 2 but smaller than the diameter of the main body 203, and an annular recess is set in the right hole with a larger aperture of the fixed sleeve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com