Automatic control device of choke manifold

A technology for choke manifolds and equipment, applied in wellbore/well components, earthmoving, flushing wellbore, etc., can solve the problem of increasing well kill control time, difficulty in real-time monitoring of casing pressure and riser pressure, unfavorable operation Personnel and managers call, analyze and summarize problems to achieve the effect of increasing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. This embodiment is carried out on the premise of the technical solution of the present invention, and detailed implementation and specific operation process are given, but the protection scope of the present invention is not limited to the following embodiments.

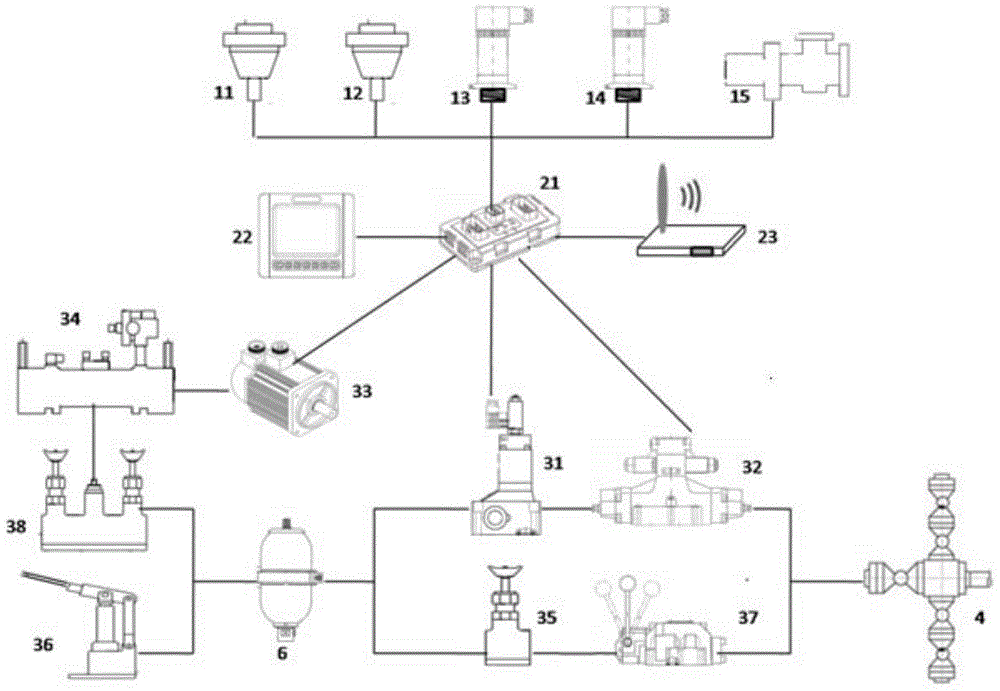

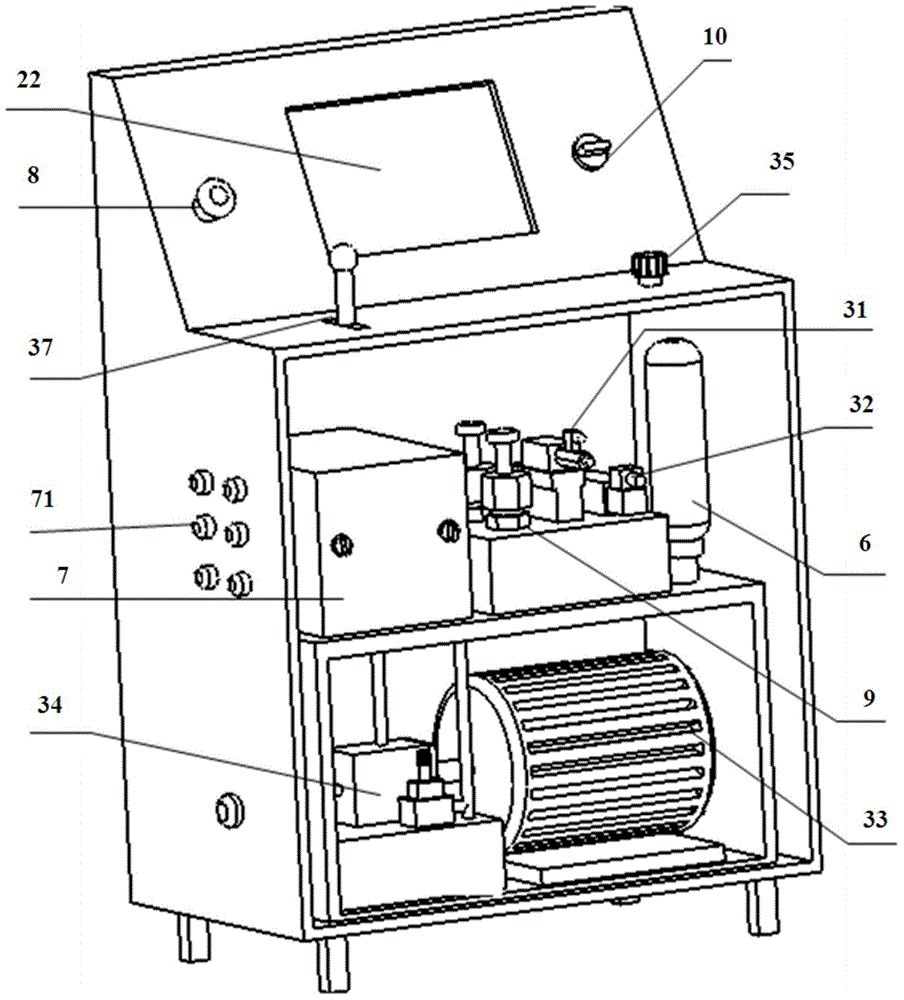

[0027] An automatic control device for a choke manifold, such as figure 1 As shown, the control device includes a sensor assembly 1, a display control assembly 2, and an execution assembly 3. The execution assembly 3 includes a proportional throttle valve 31, an electromagnetic reversing valve 32, a motor 33, a hydraulic pump 34, and a combination valve block 38. The display control The input end of component 2 is connected with sensor component 1, and the output end is respectively connected with proportional throttle valve 31, electromagnetic reversing valve 32 and motor 33, and mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com