Construction method of special-shaped curved surface roof with large span and multiple curvatures

A special-shaped curved surface and construction method technology, which is applied in roofing, building material processing, construction, etc., can solve the problems of long construction period and high cost, and achieve the effects of improving construction quality, reducing installation difficulty, and shortening construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0079] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

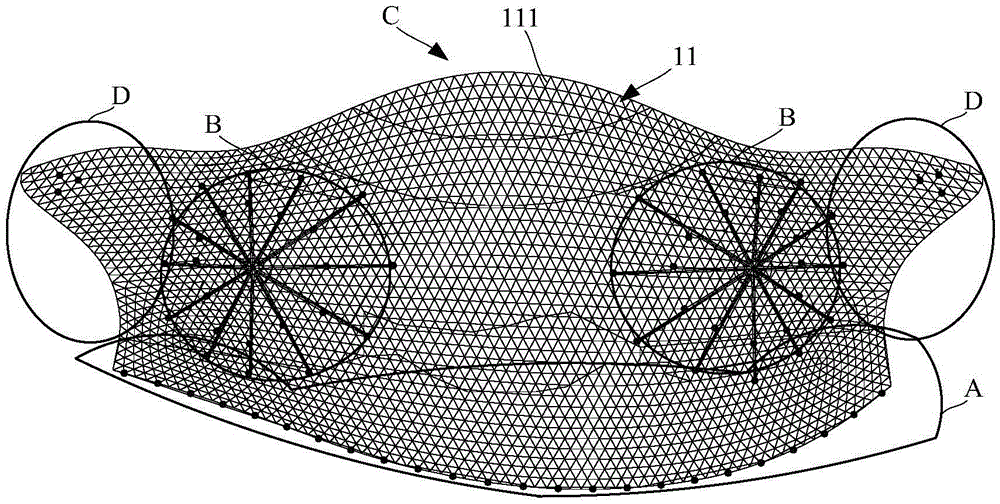

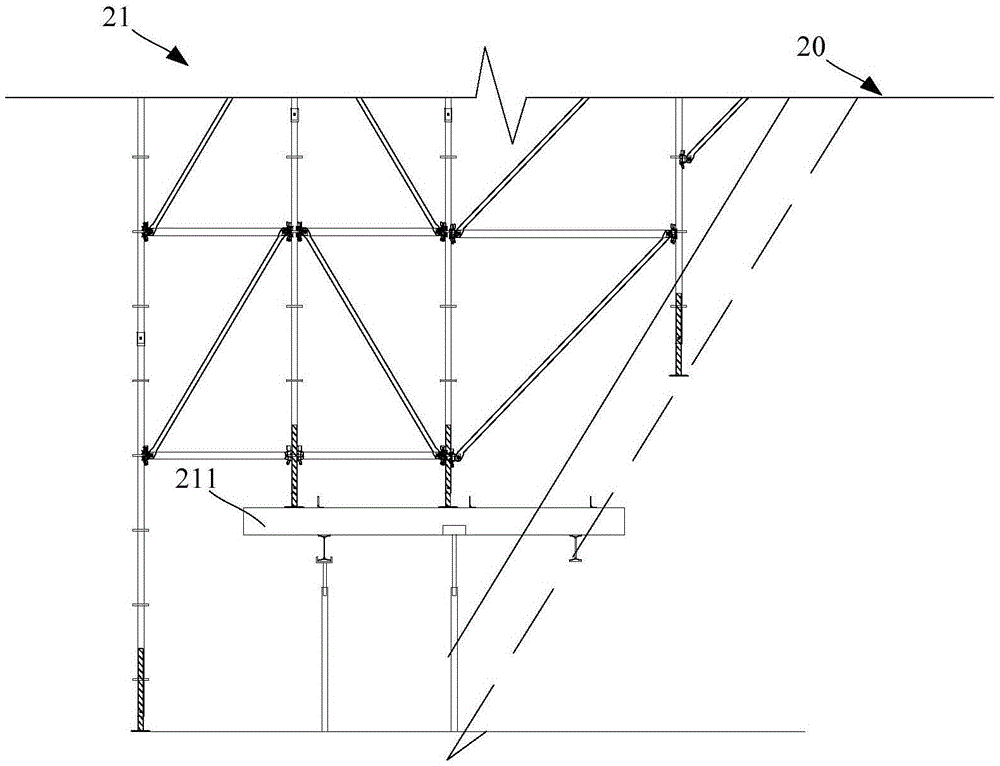

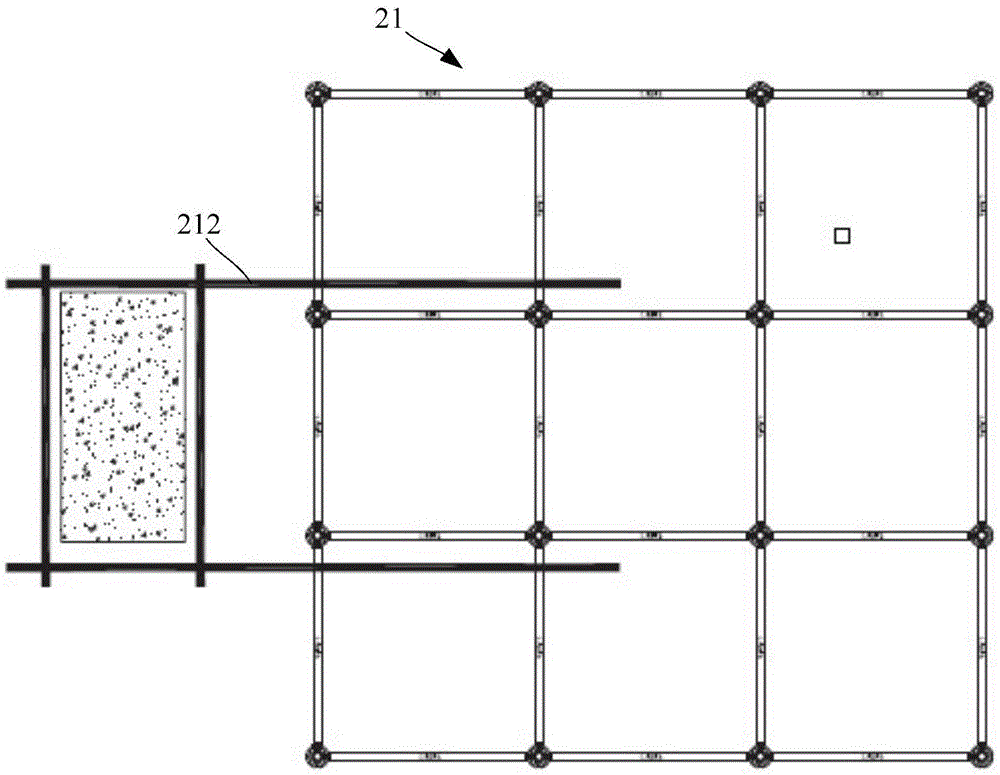

[0080] The invention provides a construction method for a large-span multi-curvature special-shaped curved roof, which is suitable for the construction of free-form surfaces, such as irregular shapes like robes. The roof adopts a hollow reticulated shell structure, which is formed by assembling aluminum alloy rods. This construction method uses SAP2000 software to analyze the force of the overall model of the supporting frame to determine the structure, size, and spacing of the supporting frame. At the same time, MIDAS (GEN ) The finite element analysis software conducts overall force analysis, stability check calculation and working condition analysis review on the slip track, unit reticulated shell and steel lattice column. Through the 1:1 full-scale simulation experiment, the unit assembly and block sliding system are tested to verify the fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com