Water discharge and drainage system and construction method adopting basement bottom plate water buoyant force releasing method

A technology of basement floor and construction method, which is applied in basic structure engineering, protection devices, construction and other directions, can solve the problems of high cost of construction of basement floor, huge impact on environmental pollution, slow construction speed, etc., and achieves low requirements for construction machinery and environmental protection. The effect of less pollution and easy access to materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0021] This embodiment takes Changhua International Commercial Center North District project located in Foshan City, Guangdong Province as an example. The project is located in the "Wufuliao" plot next to Shishan Stadium in Nanhai District, Foshan City, east of Keji North Road, and south of Boai Middle Road. To the west of Hongxing South Road, it covers an area of about 52,000 square meters, with a total construction area of about 468,000 square meters and three underground floors.

[0022] During the specific construction of this example, the following construction steps are carried out:

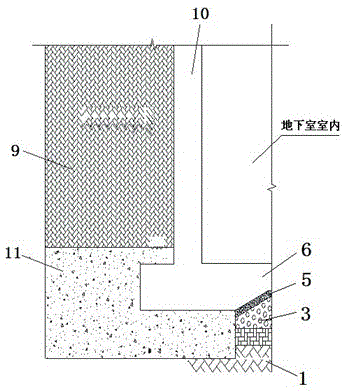

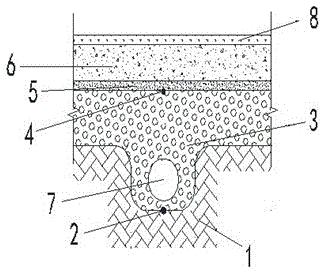

[0023] (1) if Figure 1~3 As shown, when the drainage blind ditch is excavated according to the drainage slope ≥ 0.5%, about 20 cm of earthwork should be reserved when the foundation floor is mechanically excavated to the design elevation, and manual excavation is used to ensure that the soil layer at the bottom of the foundation pit is not disturbed and damaged, reaching Undisturbed s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Permeability coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com