Construction method of comprehensive formwork for deformation joint water stop belt dowel bar of underground comprehensive pipe gallery

A technology of integrated pipe gallery and construction method, applied in water conservancy projects, artificial islands, underwater structures, etc., can solve the problems of low rigidity of wooden formwork or plastic formwork, the formwork cannot be disassembled, and increase construction costs, so as to increase turnover High efficiency, easy operation, and the effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is described in detail below in conjunction with the examples, but the examples do not constitute any limitation to the present invention.

[0027] This embodiment takes the wall and roof construction of the underground comprehensive pipe gallery project as an example to illustrate, and the specific construction steps are as follows:

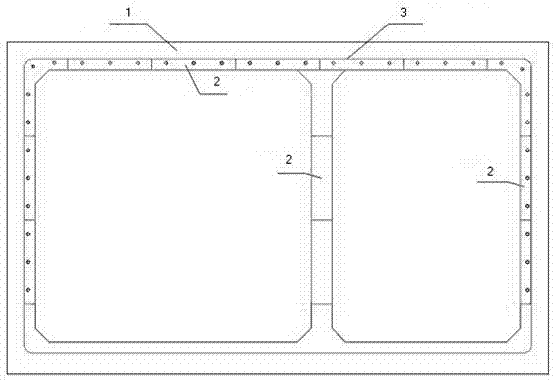

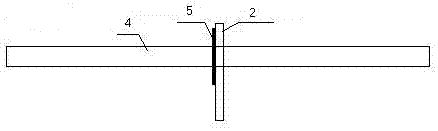

[0028] (1) Formwork layout: According to the construction drawing of the pipe gallery project, draw a large-scale layout drawing of the comprehensive formwork system (see figure 1 ), especially the large sample diagram of the shaped steel formwork on one side of the dowel bar 4; the type of shaped steel formwork is the least, and the effect is the best.

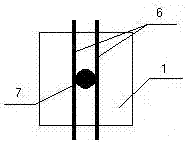

[0029] (2) Production of plastic formwork 1: Assemble the plastic formwork 1 according to the size of the cross-sectional structure, and make the inner angle of the corner mold into a circular arc angle with the steel edge rubber waterstop 3 to avoid a large gap bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com