Temporary pier construction method adopting assembled heavy steel pipe supporting device

A steel pipe support and construction method technology, which is applied in the erection/assembly of bridges, bridges, buildings, etc., can solve the problems of weak structural strength support capacity, increased construction cost, and increased construction cost, so as to reduce installation difficulty and construction cost , Reduce construction cost, reduce the effect of assembly difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

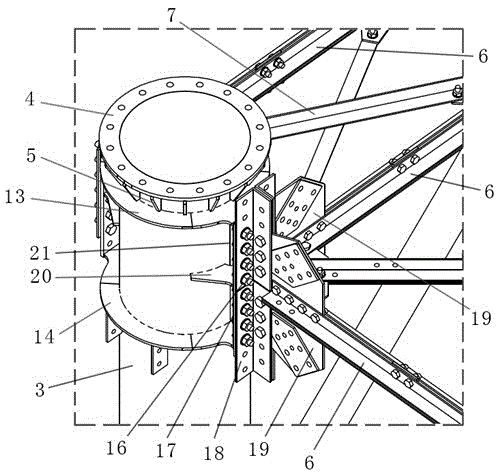

[0126] Embodiment 1: as Figure 1-8 as shown,

[0127] An assembled heavy-duty steel pipe support device, including several support segments 2 spliced in sequence in the vertical direction, the support segments 2 include several vertically arranged heavy-duty steel pipes 3, the number of the heavy-duty steel pipes 3 ensures that the support device 1 has sufficient support strength in the vertical direction, and the heavy-duty steel pipes 3 are separated by a suitable distance so that the support device 1 has sufficient stability in the horizontal direction, and connecting rods are connected between the heavy-duty steel pipes 3, so There are detachable connections between the support segments 2, between the connecting rods and the heavy steel pipe 3, and between the connecting rods and the connecting rods, and the two ends of the heavy steel pipe 3 are respectively provided with Connecting end plate 4, the connecting end plate 4 is ring-shaped, surrounding the outside of the...

Embodiment 2

[0130] Embodiment 2: as Figure 1-8 as shown,

[0131] As for the assembled heavy-duty steel pipe support device described in Example 1, each support section 2 includes four heavy-duty steel pipes 3 of the same height, and the four heavy-duty steel pipes 3 cooperate with each connecting rod to form a square frame, and the support sections 2 is a rectangular parallelepiped frame structure, the connecting rod includes a cross bar 6, the cross bar 6 is perpendicular to the central axis of the heavy-duty steel pipe 3, and the two heavy-duty steel pipes 3 in the same length plane of the support segment 2, A cross bar 6 is connected between the inner side and the inner side of the upper end, and a cross bar 6 is also connected between the outer side and the outer side. The two heavy-duty steel pipes 3 in the same length plane of the support segment 2 are connected between the inner side and the inner side of the upper end. The cross bar 6 is the first cross bar 6, the cross bar 6 c...

Embodiment 3

[0133] Embodiment 3: as Figure 1-8 as shown,

[0134] As for the assembled heavy-duty steel pipe support device described in Embodiment 2, the cross support 7 is a split structure, including a first support rod 71 and a second support rod 72 arranged crosswise, the first support rod 71 and the second support rod 72 The second support bar 72 crosses in an X shape, the first support bar 71 and the second support bar 72 are angle steel, the outer side wall of the first support bar 71 is in contact with the outer side wall of the second support bar 72, a cross bar There are two cross supports 7 in the group, each cross support 7 corresponds to a heavy steel pipe 3, two cross supports 7 in the same cross bar assembly, the first cross bar of one cross support 7 6 is parallel to the second cross bar 6 of another cross support 7. The first support bar 71 and the second support bar 72 are non-universal components, which are produced according to the size requirements of on-site assem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com