Processing device for fabric production process

A production process and processing device technology, which is applied in the field of processing devices and processing devices in the fabric production process, can solve the problems of violating the requirements of color, comfort and fashion, and cannot guarantee the coloring effect of fabrics, and the color and luster are not stable enough. Achieve the effect of saving dyeing time, improving dyeing effect and maintaining uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

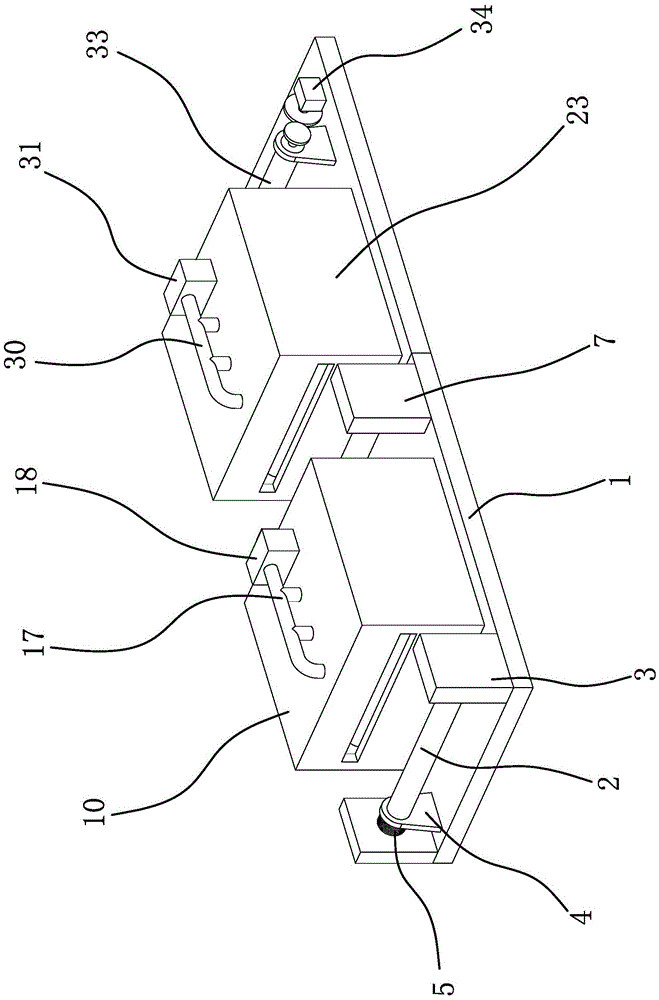

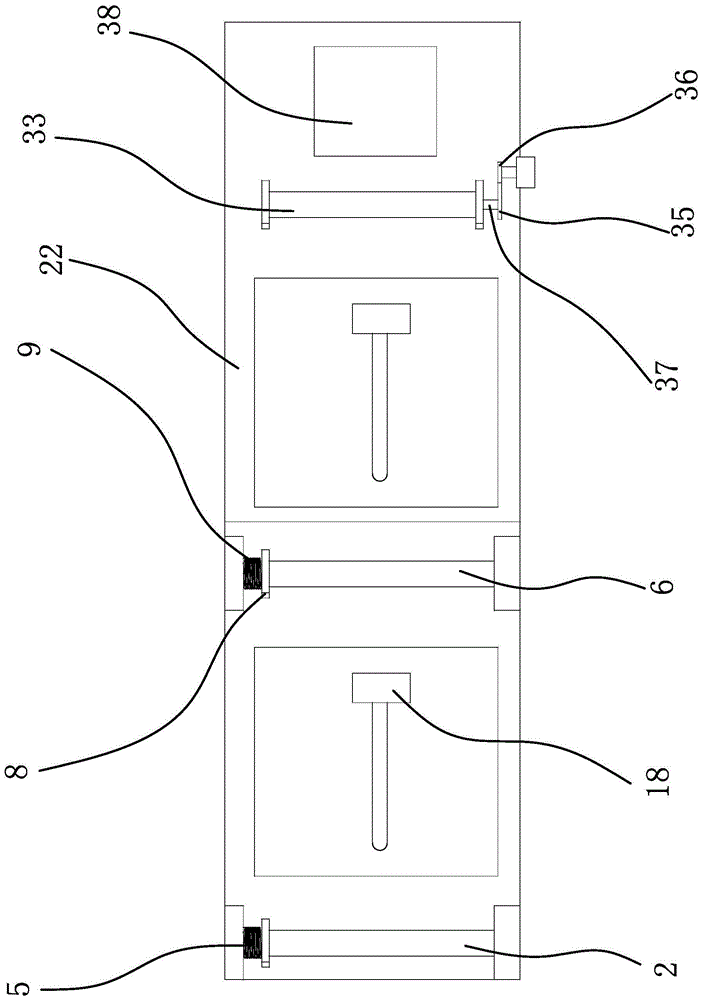

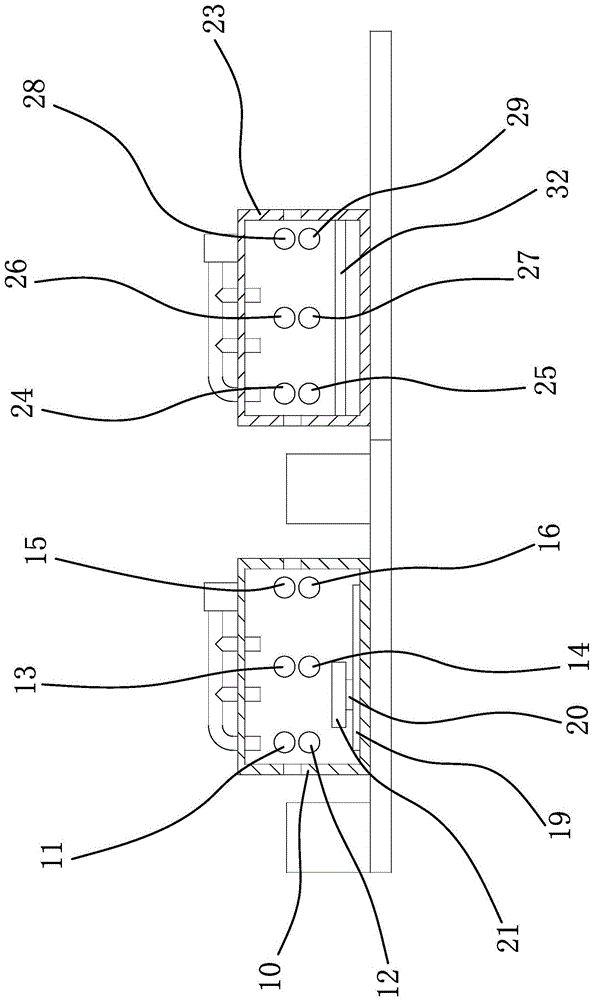

[0024] Such as figure 1 and figure 2 As shown, the cryogenic processing device includes a frame 1, on which a left rotating shaft 2 and a right rotating shaft 6 symmetrical to each other are arranged, one end of the left rotating shaft 2 is provided with a left bearing, and the left rotating shaft 2 is additionally One end is fixed with a left positioning part 3, and one end surface of the left positioning part 3 facing the left shaft is provided with a non-circular left positioning groove, a left bearing seat 4 is arranged outside the left bearing, and a Left spring 5, one end of left spring 5 is fixed on the left bearing seat 4, and the other end of left spring 5 is fixed on the frame 1; One end of right rotating shaft 6 is provided with right bearing, and the other end of right rotating shaft 6 is fixed with right positioning Part 7, the right positioning part 7 is provided with a non-circular right positioning groove on one end face of the right rotating shaft, a right b...

Embodiment 2

[0032] The structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is: in Embodiment 1, the oxygen supply device includes an oxygen supply machine, an oxygen supply pipe 45 and an air-distributing foam board 44; and in this embodiment In the second, the oxygen supply device includes an oxygen supply machine, an oxygen supply pipe and a nozzle, the air outlet of the oxygen supply machine is connected to the oxygen supply pipe 45, and the nozzle is placed on the bottom of the convection chamber, and the exhaust port of the oxygen supply pipe 45 is connected to the nozzle . Tiny oxygen bubbles are evenly released from the bottom of the cavity, so that the bubbles move upward continuously, and finally spill out from the cylinder head 39. During the countercurrent process of the bubbles, on the one hand, they react with the dye solution, and on the other hand, the temperature of the dye solution is further enhanced. and uniformity o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com