Grooving, gluing and band pressing mechanism of edge sealing band

An edge banding and gluing technology, which is applied in coating, device for coating liquid on the surface, metal processing, etc. edge, improve the efficiency and quality of edge sealing, and avoid the effect of poor quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

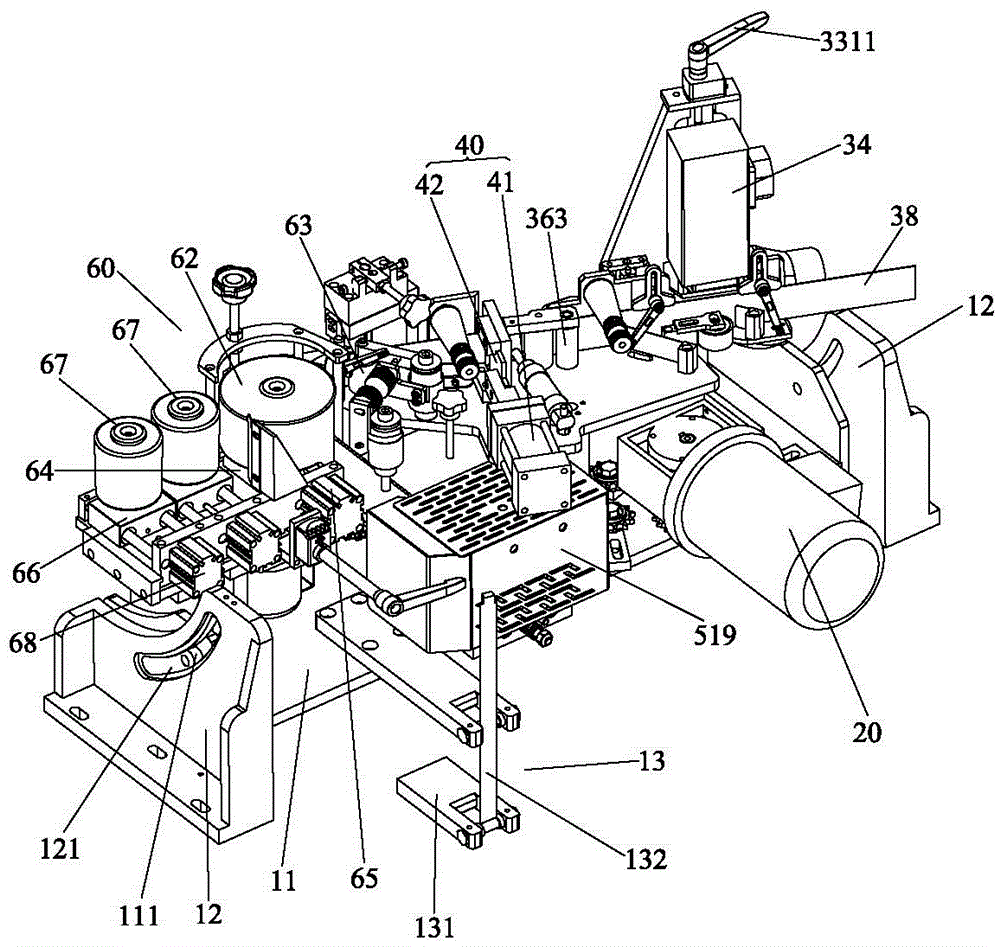

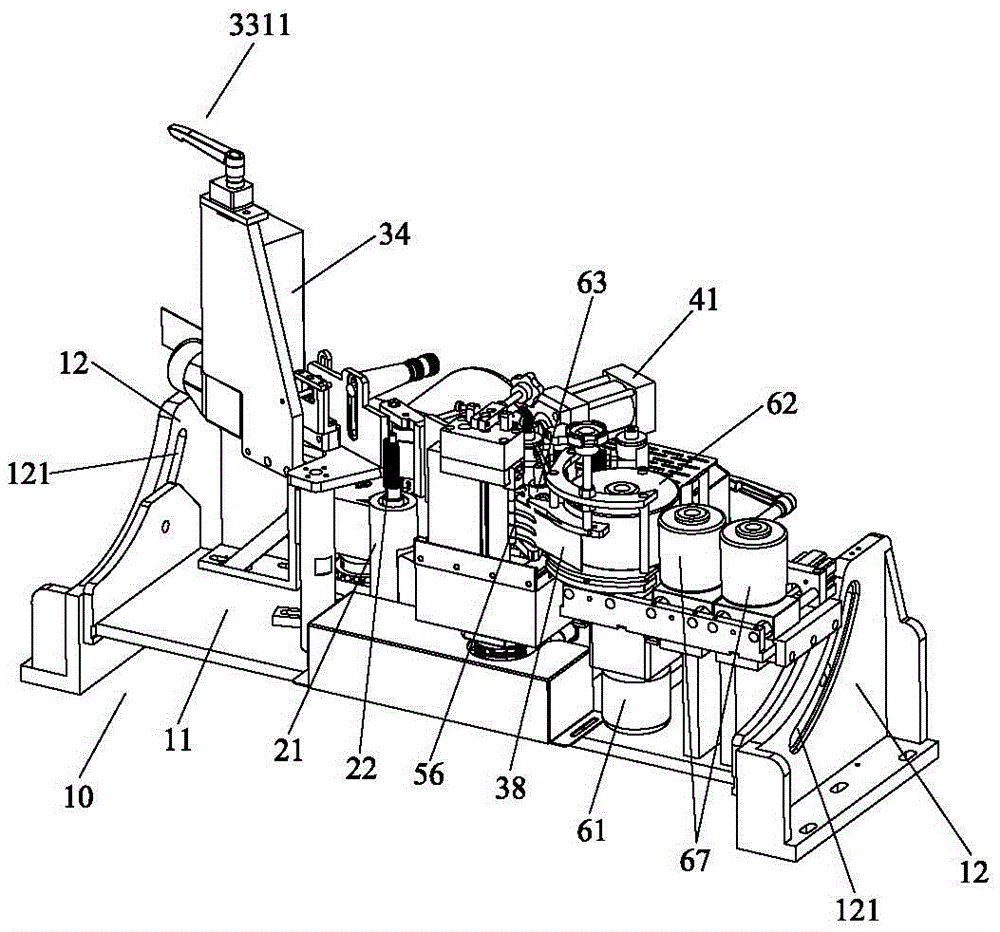

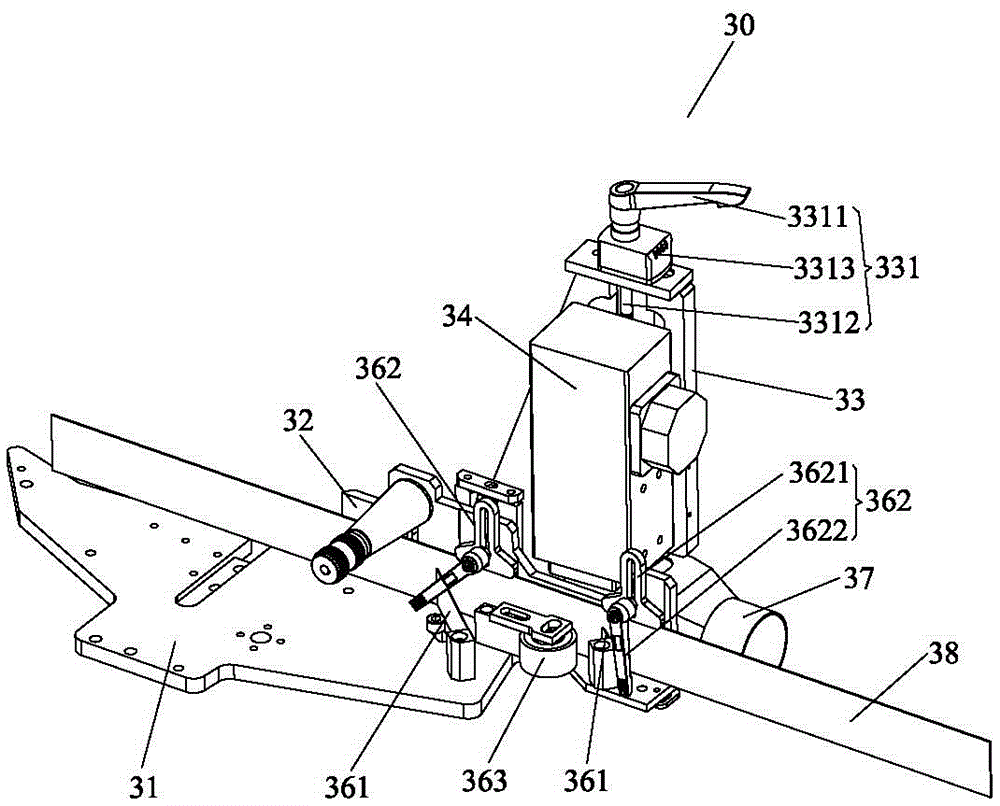

[0065] The present invention as Figure 1 to Figure 12 As shown, an edge banding groove glue coating and pressing mechanism includes a frame 10, a transmission mechanism 20 installed on the frame 10, a groove mechanism 30, a cutting mechanism 40, a beveled edge sealing glue supply mechanism 50 and Press belt guiding mechanism 60, wherein:

[0066] The frame 10 includes a support plate 11 and vertical plates 12 positioned on both sides of the support plate 11, arc-shaped slide grooves 121 are correspondingly provided on the two vertical plates 12, and an adjusting rod 111 is respectively provided at both ends of the support plate 11. One end of the adjusting rod 111 stretches out from the support plate 11 and is slidably connected to the arc-shaped chute 121. The above-mentioned mechanisms are installed on the support plate 11; An adjustment mechanism 13, the angle adjustment structure 13 has a support 131 and a screw 132 installed on the support 131 to drive the support plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com