Ceramic fiber cutting device

A cutting device and ceramic fiber technology, applied in welding equipment, laser welding equipment, metal processing equipment, etc., can solve the problems of low operating accuracy, long optical path, increased machine weight, etc., achieve high positioning accuracy, ensure cutting accuracy, The effect of reducing the span

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

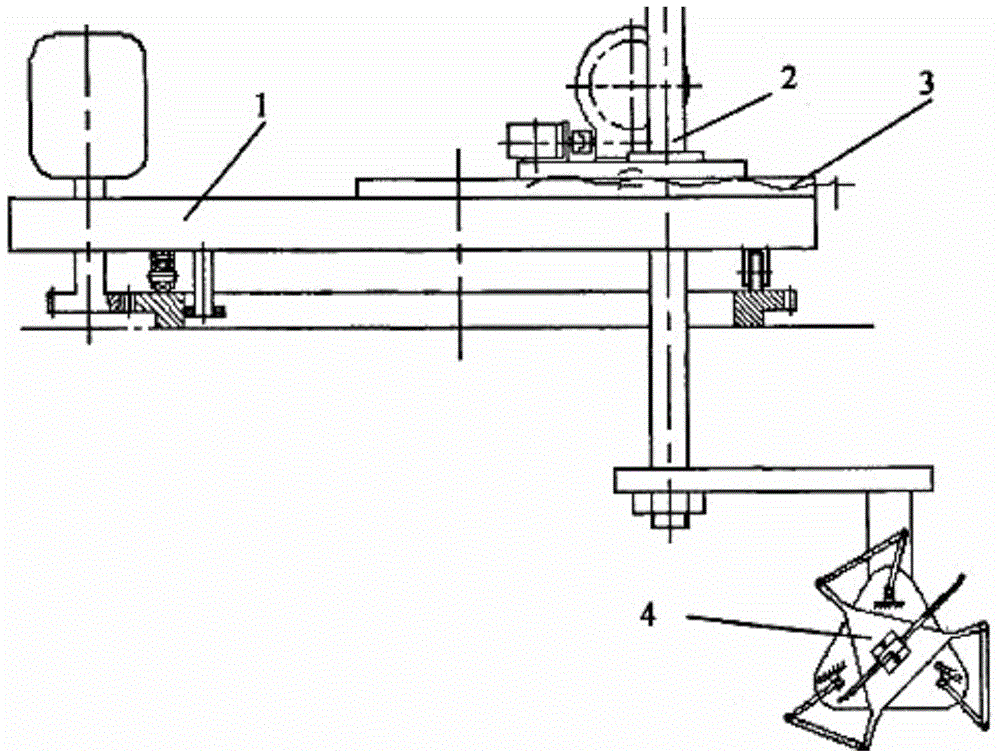

[0016] Embodiment: A ceramic fiber cutting device of the present invention consists of a horizontal rotation mechanism 1, a vertical lifting mechanism 2, a radial adjustment mechanism 3 and a swing mechanism 4, and a radial adjustment mechanism 3 is installed on one side of the horizontal rotation mechanism 1, and a vertical lifting mechanism 2 is installed vertically through the radial adjustment mechanism 3, and the lower end of the vertical lifting mechanism 2 is connected to the swing mechanism 4.

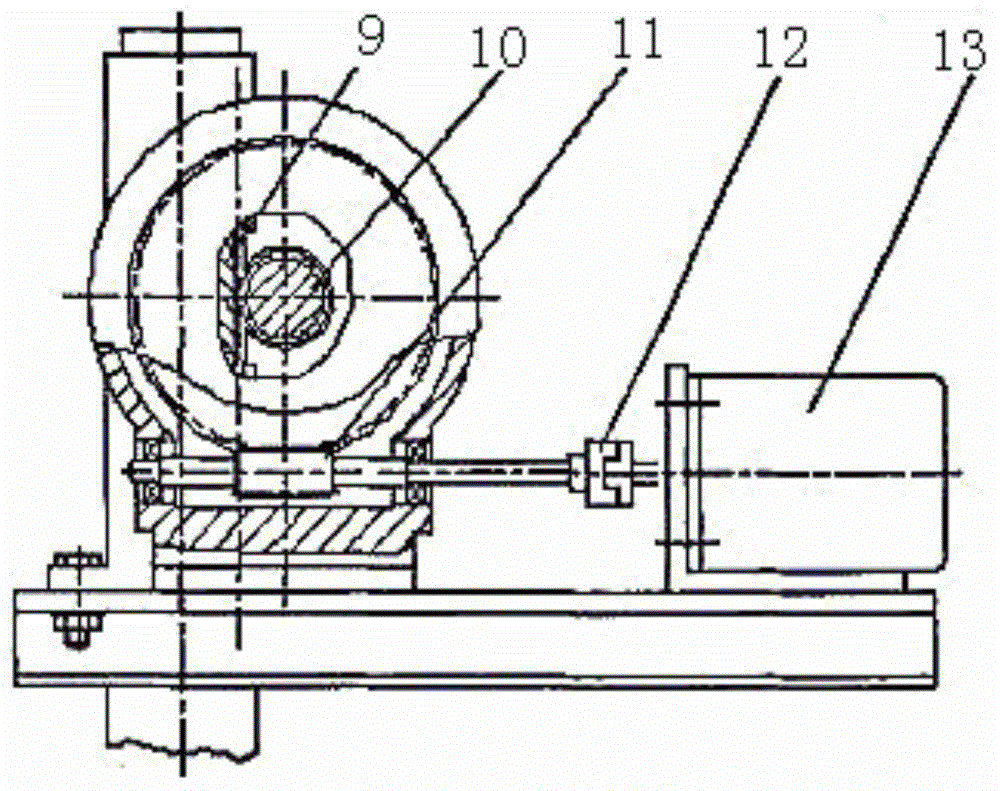

[0017] The horizontal rotation mechanism 1 includes a stepping motor 5 and a slewing bridge 6, the stepping motor 5 is installed on one end of the slewing bridge 6, the small ring gear 8 is connected to the stepping motor 5, and the large ring gear 7 mounted on the base is connected to the pinion 8 . The slewing bridge composed of two rails is placed on the large ring gear, and four rolling bearings are fixed under the slewing bridge to form a four-point support with the large ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com