Automatic large pipeline cutting machine

A cutting machine and cutting mechanism technology, applied in the direction of metal sawing equipment, sawing machine, metal processing equipment, etc., can solve the problems of unsuitable submarine pipelines, low quality requirements for end faces, and inability to meet the cutting requirements of submarine pipelines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

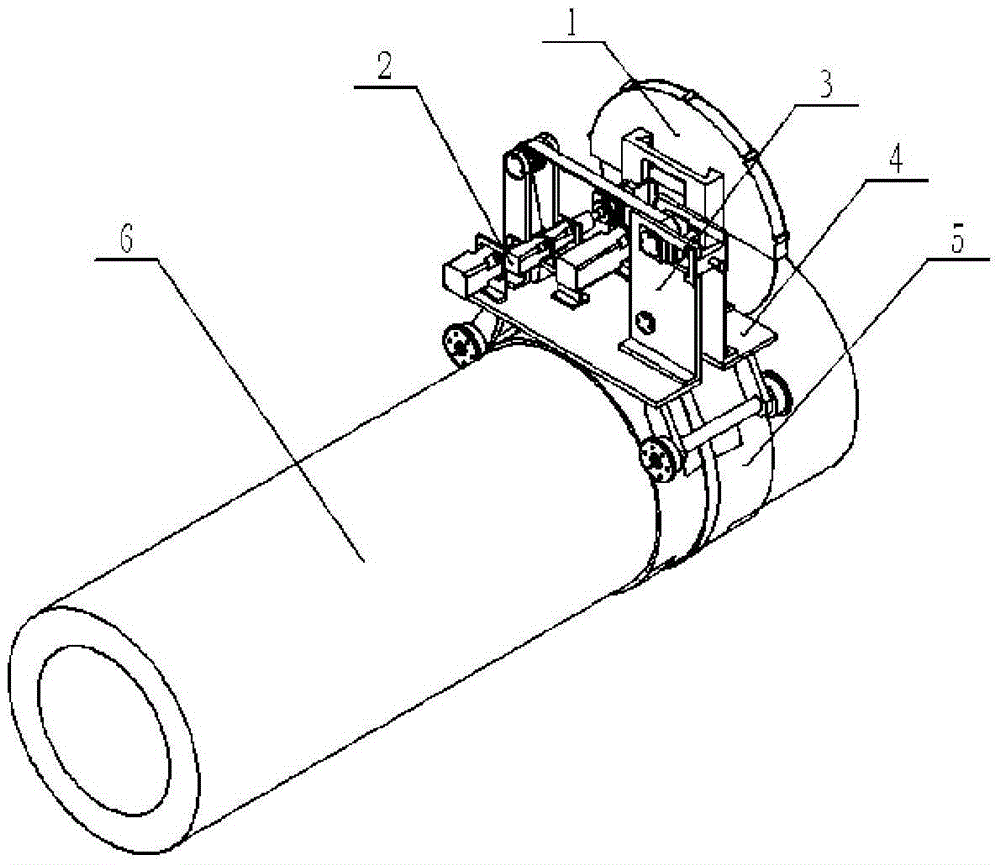

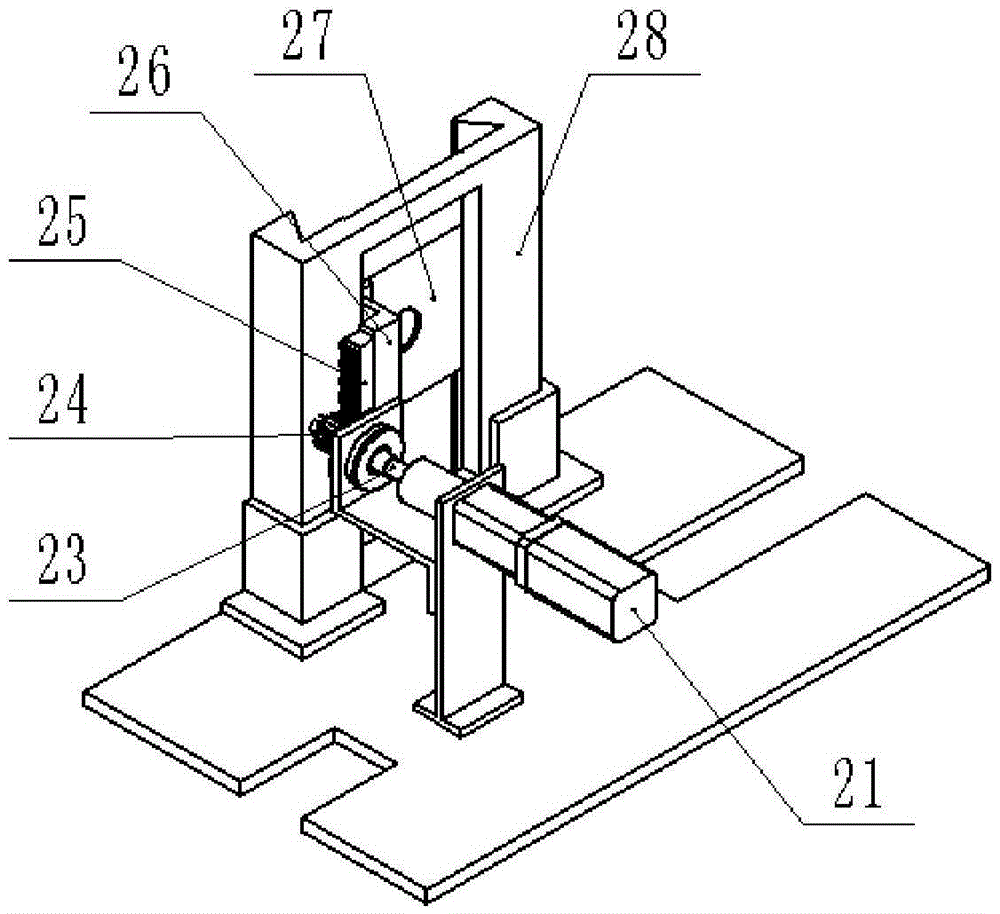

[0033] The large-scale pipeline automatic cutting machine provided by the present invention comprises a cutting mechanism 1, a lifting mechanism 2, a circular traveling mechanism 3, an installation base plate 4 and a circumferential track 5; the circumferential traveling mechanism and the lifting mechanism are all installed on the installation base plate, and the circumferential track surrounds the pipeline to be cut 6 Circumferential installation, the circular walking mechanism moves along the circular track and drives the installation bottom plate to move circularly along the pipeline to be cut; the cutting mechanism is installed at the end of the lifting mechanism.

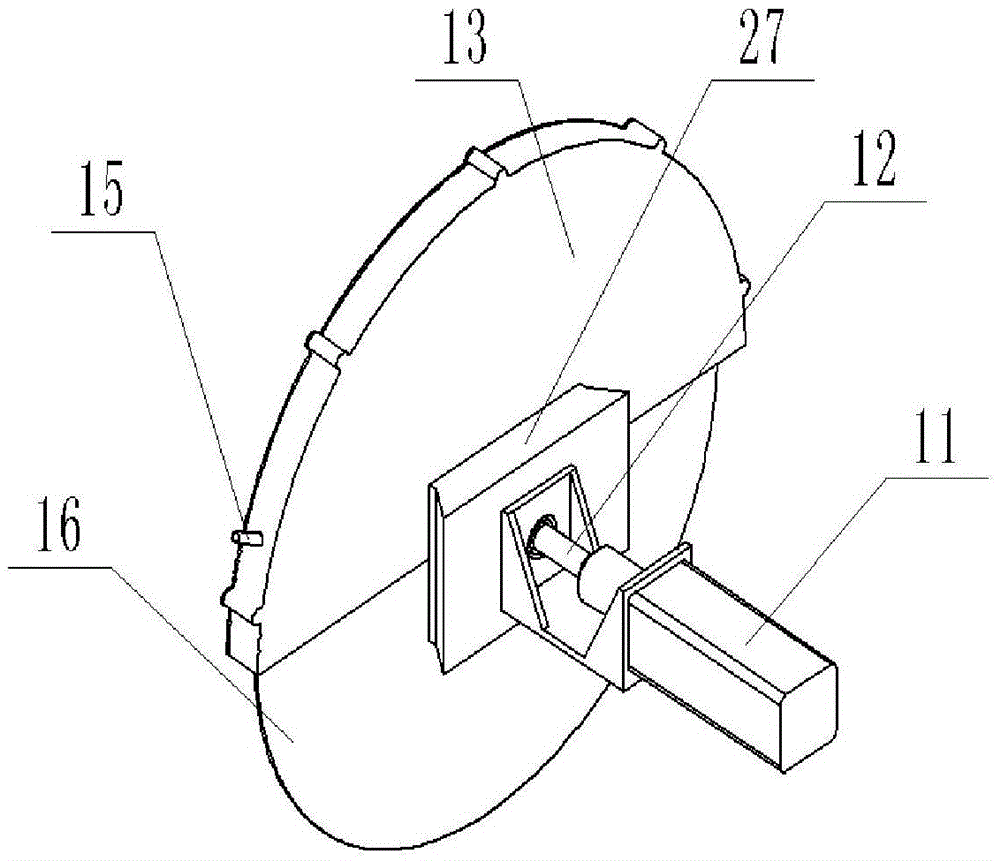

[0034] The circular track is a cylindrical circular track formed by splicing arc-shaped guide rails 51. The arc-surface guide rails 51 are connected and fixed by fastening screws 52. The inner surface of the circular track is in close contact with the outer surface of the pipe to be cut. There are convex ribs on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com