Automatic cutting device of multi-connected pipe fittings

A technology of automatic cutting device and one-piece pipe, which is applied in the direction of sawing machine, sawing machine accessories, metal sawing equipment, etc., can solve the problem of not being able to adapt to large-scale industrial production, which has not been better solved, and takes up a lot of manpower and Equipment and other issues, to achieve the effect of improving cutting production efficiency, reducing technical level requirements, and reducing equipment and construction investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

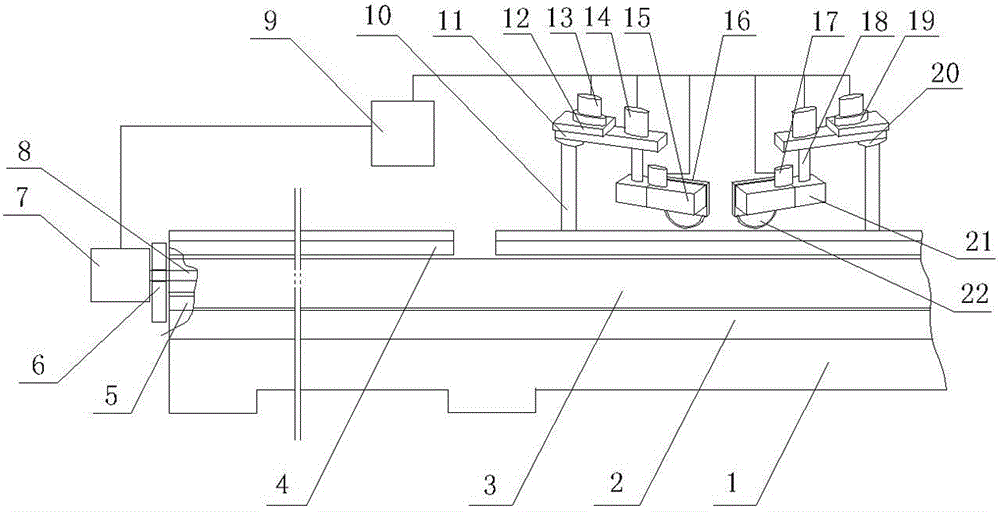

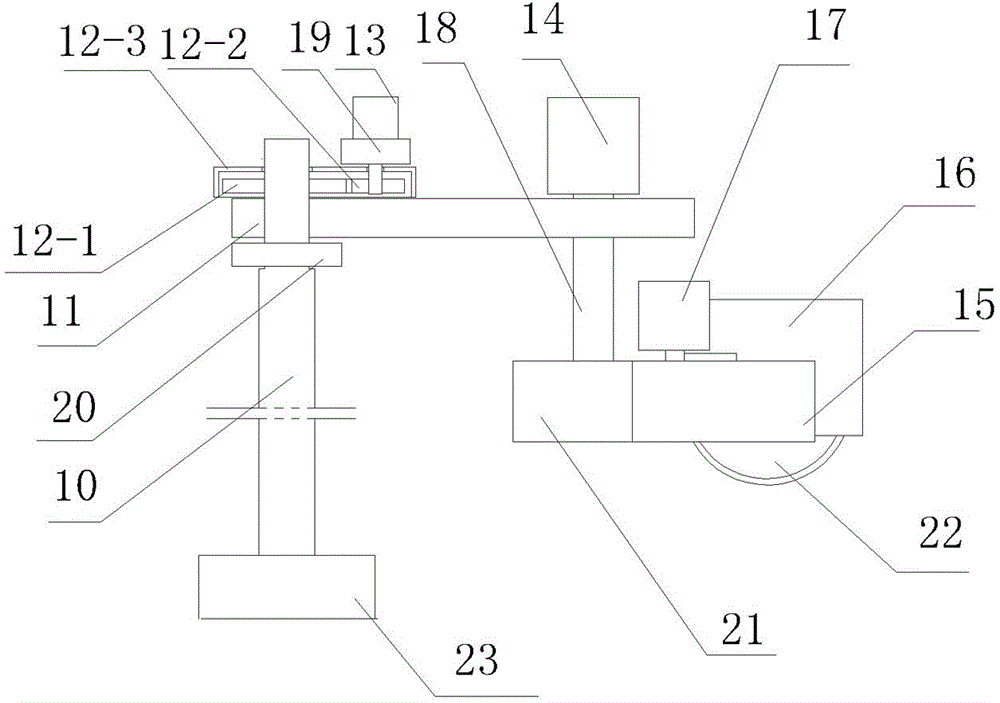

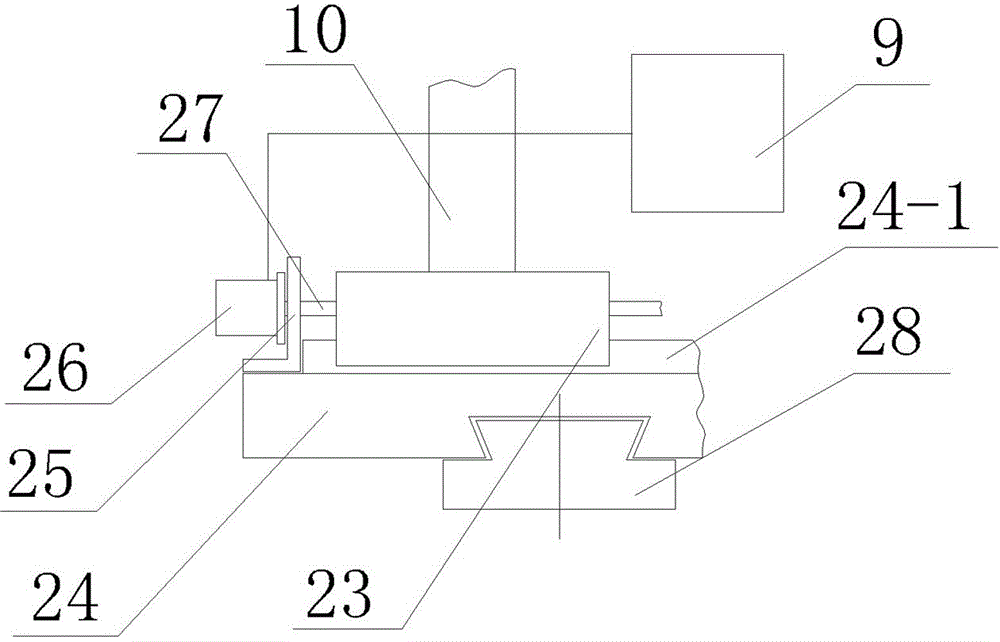

[0025] like figure 1 , figure 2 As shown, the multi-joint pipe automatic cutting device of the present invention, the multi-joint pipe automatic cutting device includes 2 saw blade cutting machines, multi-joint elbow cutting mold 4 and controller 9, and the multi-joint elbow The bottom of the cutting mold 4 is provided with a mold movement adjustment mechanism, and the saw blade cutting machine and the mold movement adjustment mechanism are connected with the controller 9 for signals. The saw blade cutting machine comprises a machine base 23, a column 10, a tray 20 and a rotating arm 11, a saw blade angle adjustment mechanism 12 is arranged between the rotating arm 11 and the column 10, one end of the rotating arm 11 is connected with the column 10 through wear, and the other end is A rotary cutting head is set, and the rotary cutting head is connected with the rotating arm 11 through a lifting mechanism, and the rotary cutting head is provided with a rotary cutting saw blad...

Embodiment 2

[0030] combine figure 1 , figure 2 see image 3 Figure 4 , the multi-joint pipe automatic cutting device of the present embodiment, the multi-joint pipe automatic cutting device includes 2 saw blade cutting machines, a multi-joint elbow cutting mold 4 and a controller 9, and the multi-joint elbow cutting The bottom of the mold 4 is provided with a mold movement adjustment mechanism, and the saw blade cutting machine and the mold movement adjustment mechanism are connected with the controller 9 for signals. The saw blade cutting machine includes a machine base 23, a column 10, a tray 20 and a rotating arm 11. A saw blade angle adjustment mechanism is arranged between the rotating arm 11 and the column 10. One end of the rotating arm 11 is connected with the column 10 through clothing, and the other end is provided with a Rotary cutting head, the rotary cutting head is connected with the rotating arm 11 through a lifting mechanism, and the rotary cutting head is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com