A double-station cutting mechanism

A dual-station, cutting technology, applied in the direction of cutting devices, manufacturing tools, metal processing equipment, etc., can solve the problems of low cutting efficiency and increase production costs, and achieve the goal of reducing production costs and improving cutting production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the objectives, technical solutions, and advantages of the present invention clearer, the following further describes the present invention in detail with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

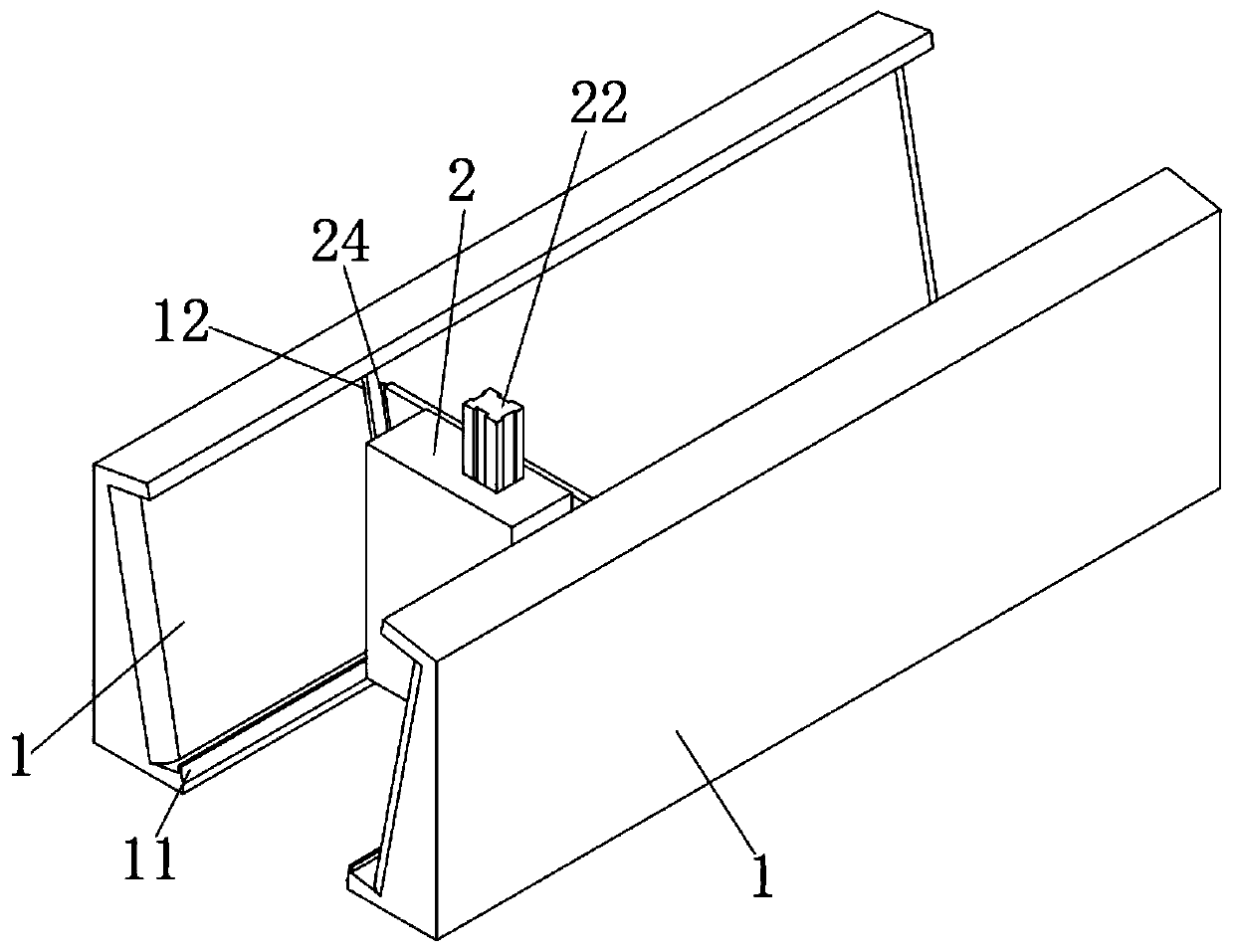

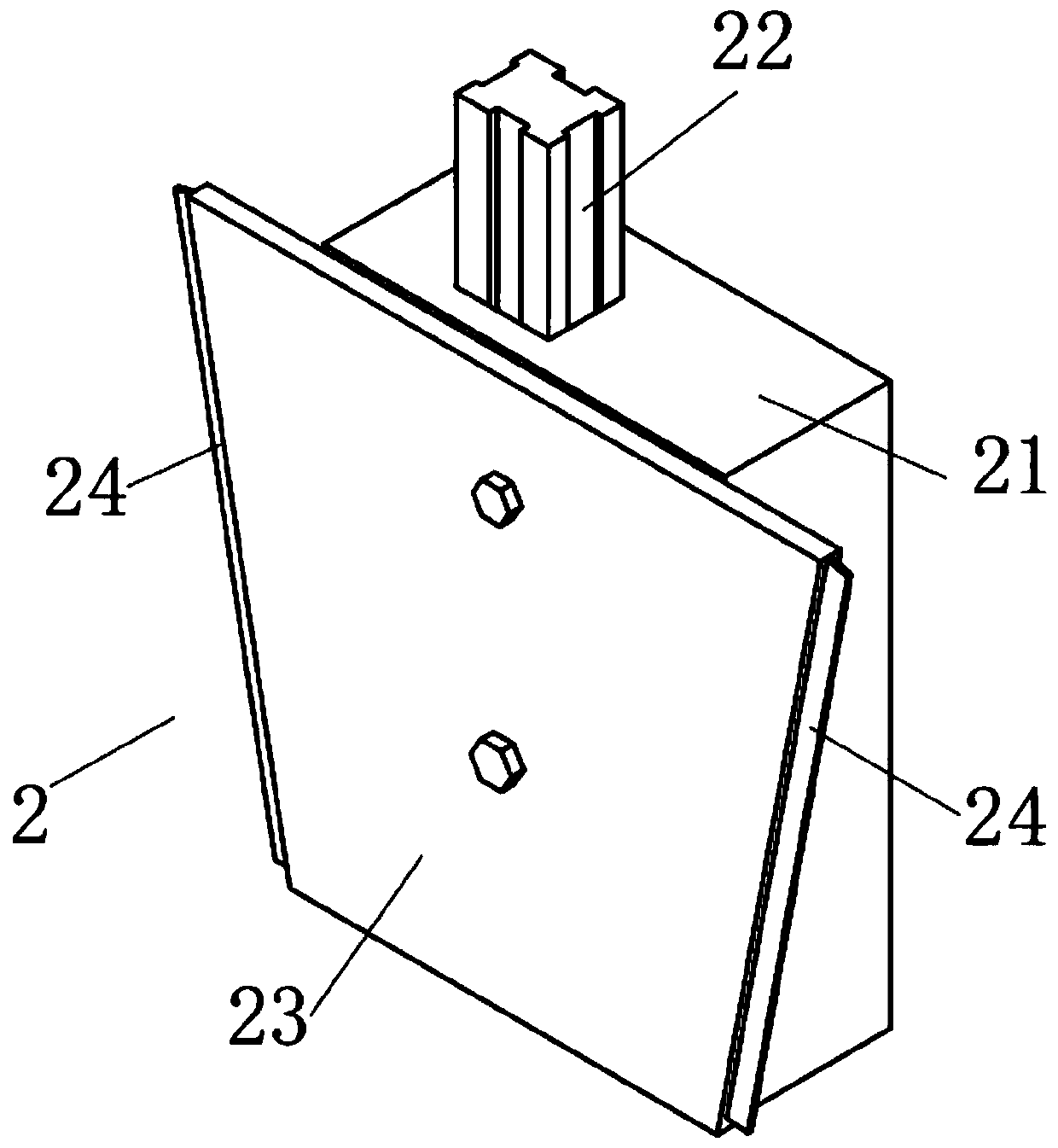

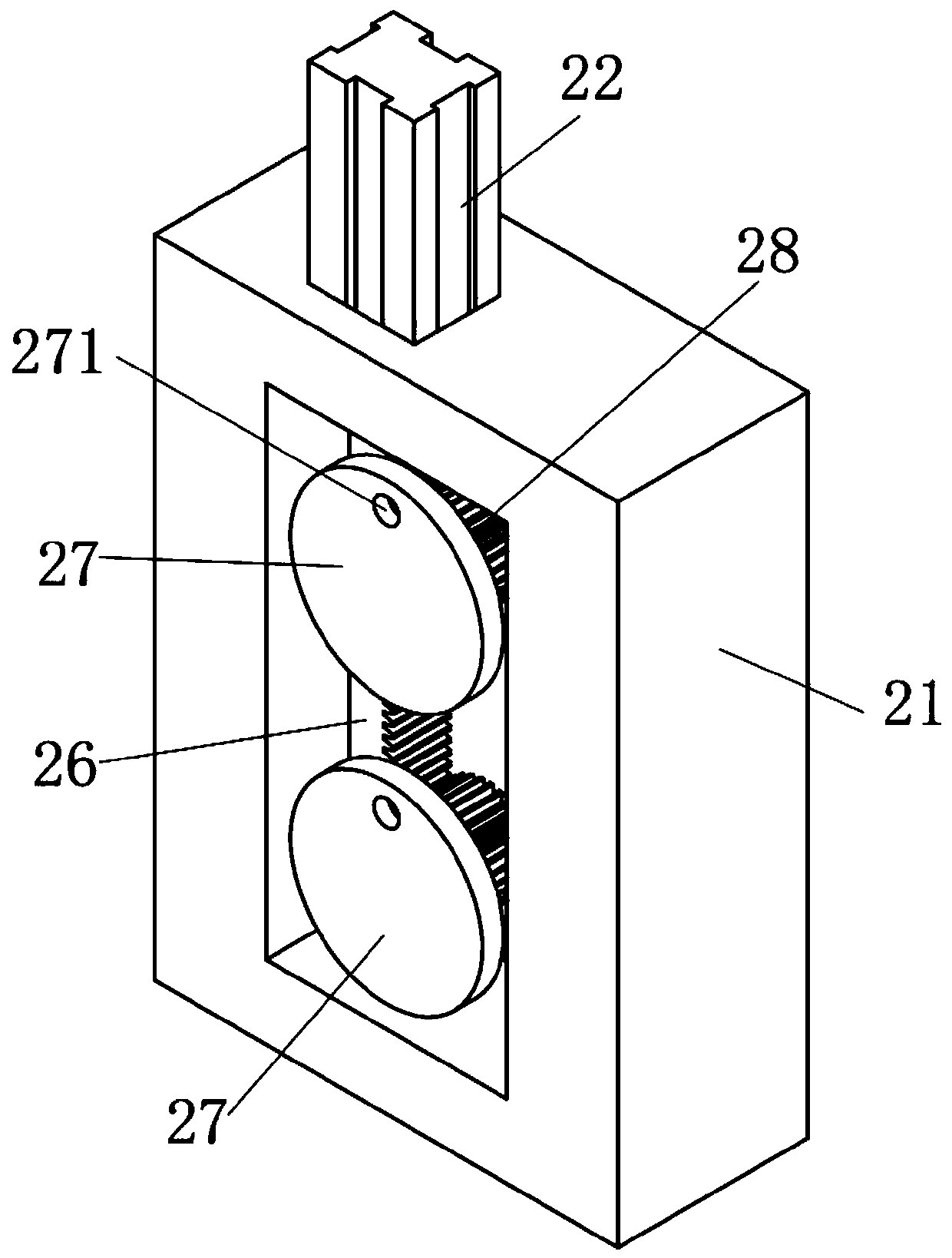

[0017] reference Figure 1 to Figure 3 , A double-station cutting mechanism, comprising a feeding table 1 and a cutting mechanism 2; the feeding table 1 specifically has two, which are arranged at opposite intervals, and the cutting mechanism 2 is located between the two feeding tables 1 The two conveying platforms 1 have their conveying faces away from the cutting mechanism 2 and are inclinedly arranged on the side; the cutting mechanism 2 includes a bracket 21, a cutting cylinder 22, a moving plate 23 and a cutting knife 24; the bracket 21 is provided with a rack 26 and a turntable 27; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com