Butterfly plastic-fiber filter material shearing machine

A technology of shearing machine and filter material, which is applied in metal processing and other fields, and can solve the problems of low output efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

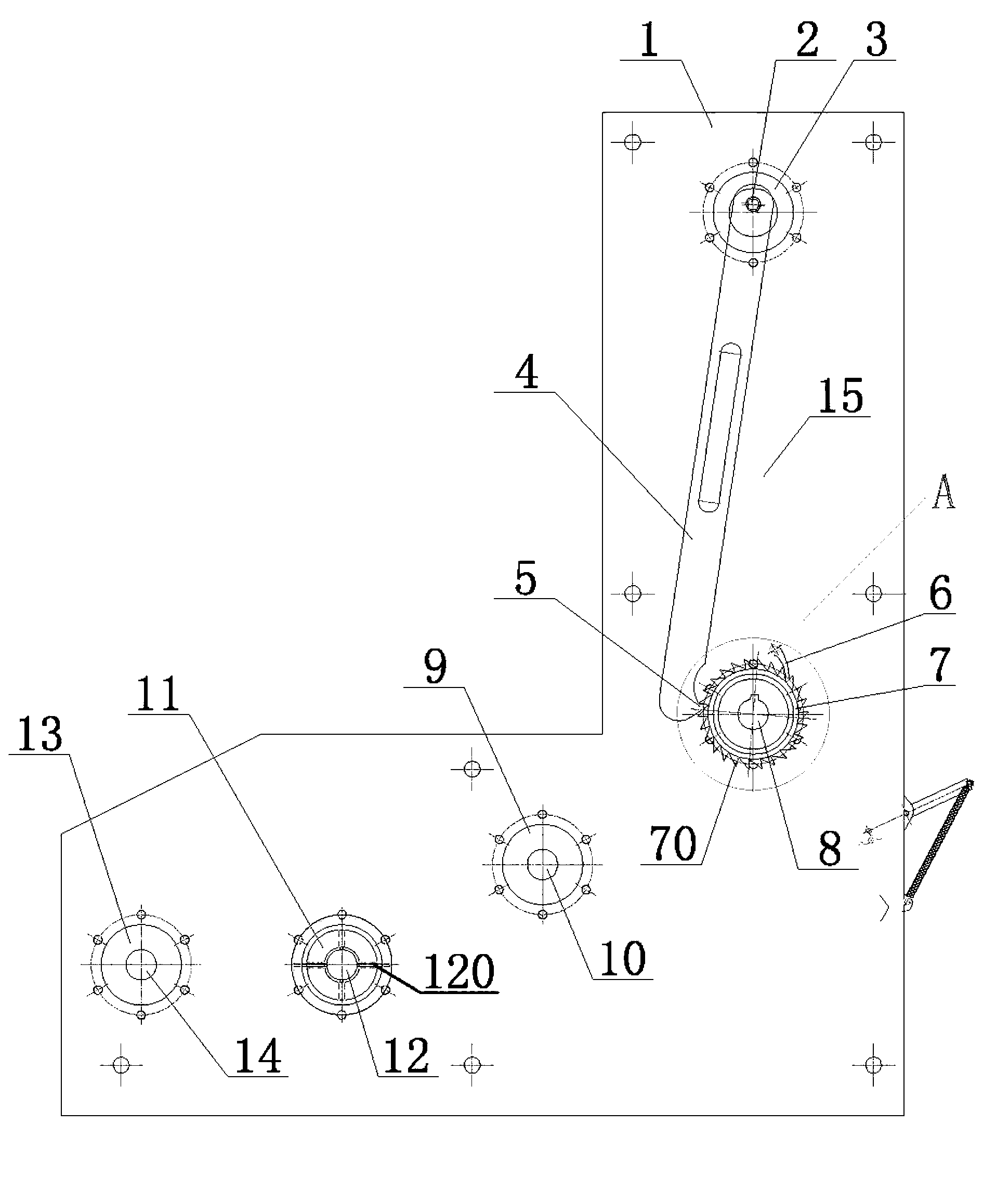

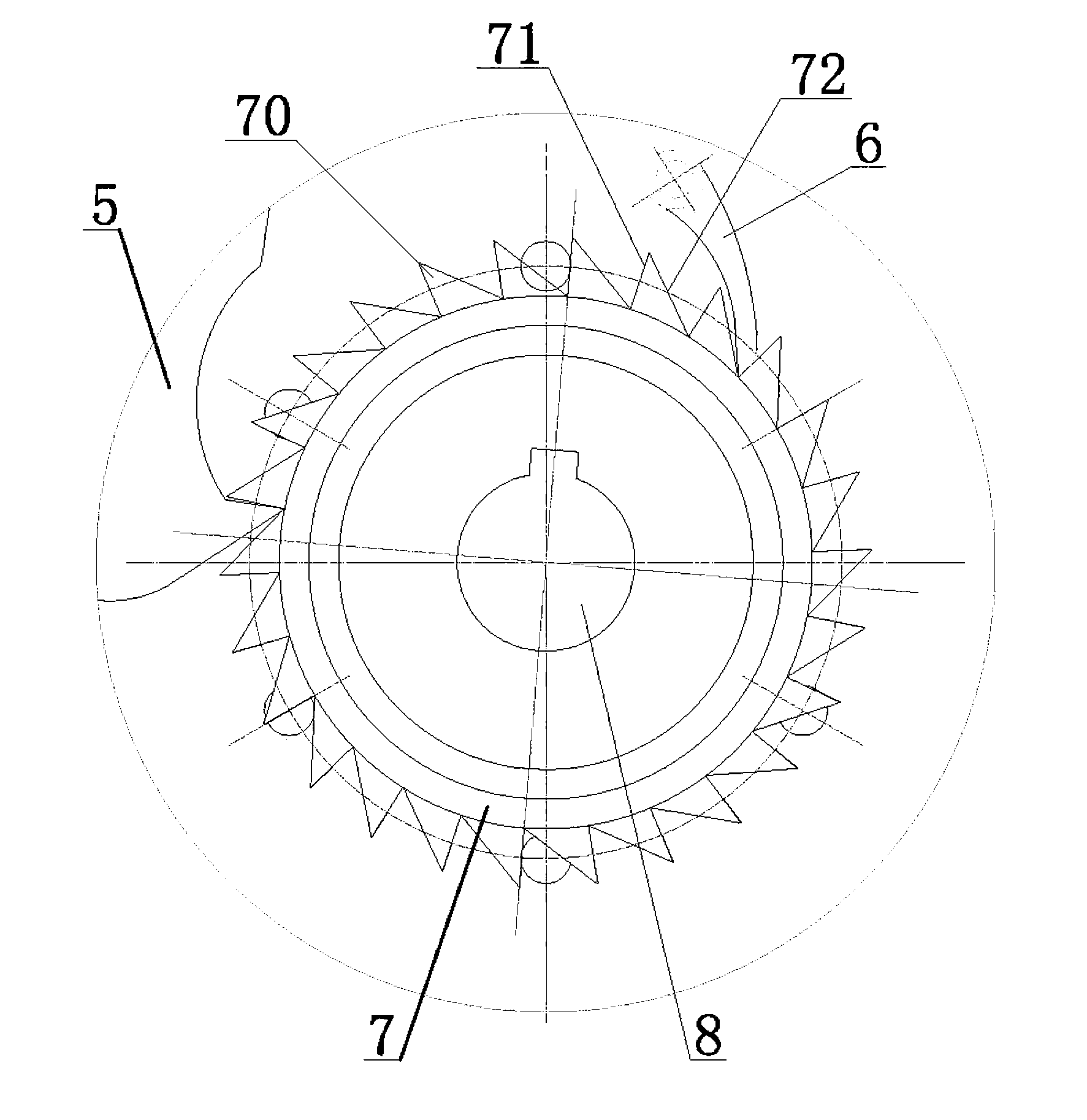

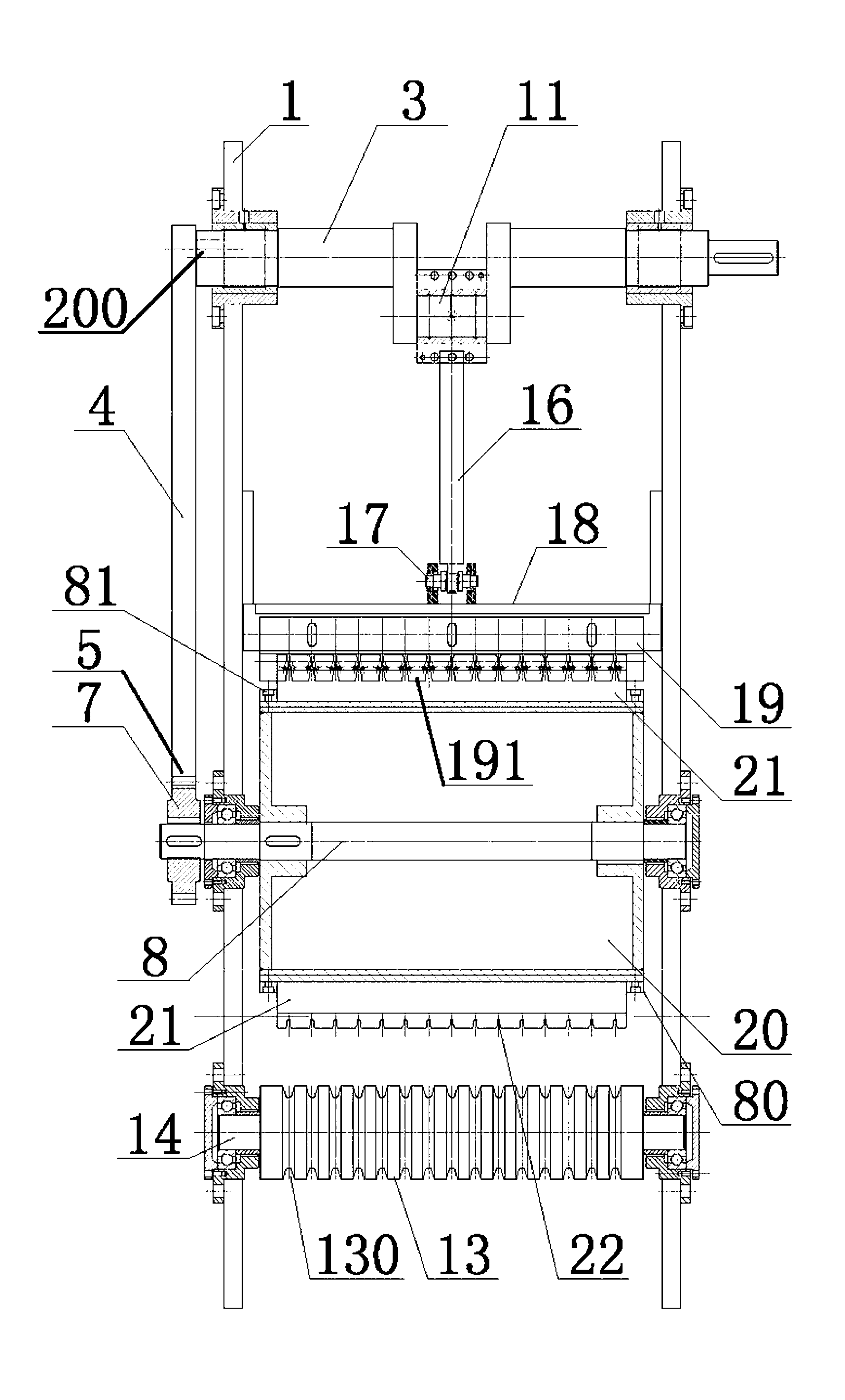

[0030] A butterfly plastic fiber filter material shearing machine, such as figure 1 , image 3 with Figure 4 As shown, the first rotating roller guide, the rotating roller pull pretensioner, the second rotating roller guide and the intermittent rotation pulling pretensioner are sequentially installed on the frame 1 from the front to the rear. The structure of the tension cutting stripper, the first rotating roller guide and the second rotating roller guide are: an annular guide groove around the central axis of the cylinder is arranged on the outer peripheral wall of the cylinder, and all the annular guides The grooves are distributed along the axial direction of the cylinder, and the rotatable cylinder (through the bearing and the rotating shaft) is installed on the frame 1, such as Figure 5 with Image 6 Shown is the structure of the first rotating roller guide, the first rotating roller guide is composed of a first cylinder 13, and on the outer peripheral wall of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com