Hydrogen-evolution catalyst and preparation method thereof

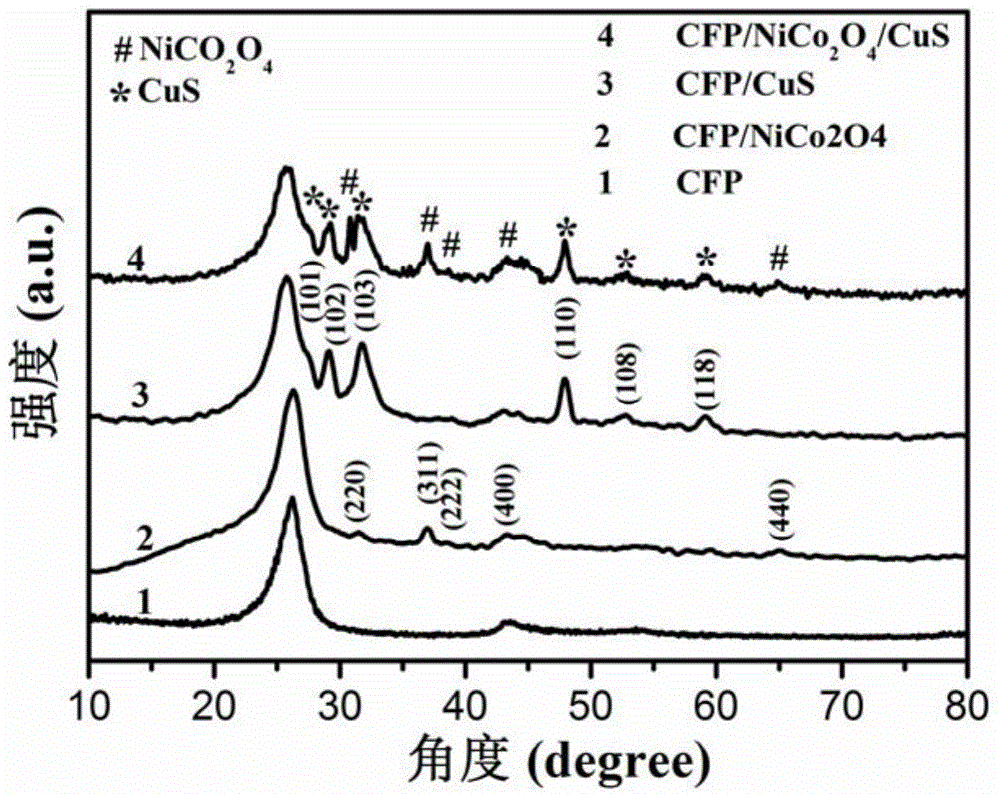

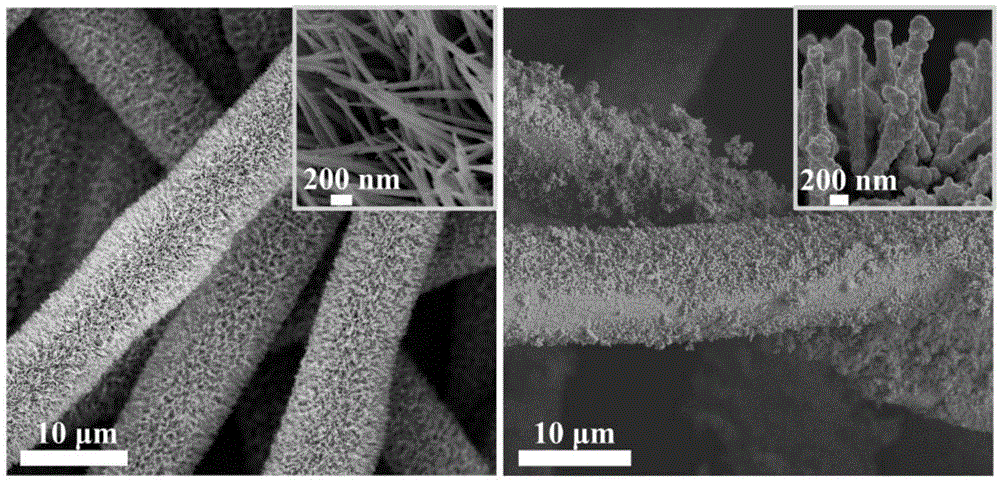

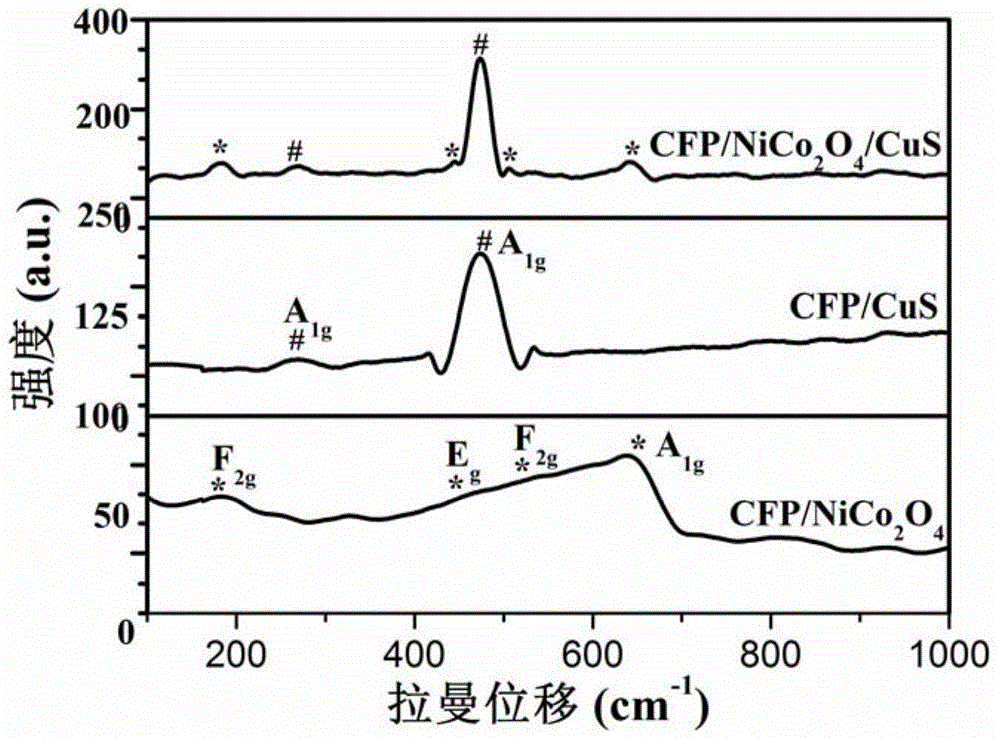

A catalyst and hydrogen evolution technology, applied in the field of electrochemical catalysis, can solve the problems of scarcity, expensive Pt metal, high resistance, etc., and achieve the effect of increasing active sites, increasing surface area, and good conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] 1) Put two pieces (3×4cm 2 ) Carbon paper into 0.5MH 2 SO 4 Ultrasound in the solution for 30 minutes, take it out and wash it with ethanol and water several times, and place it in a vacuum drying oven at 30°C to dry;

[0062] 2) Take 0.66g of cobalt nitrate, 0.33g of nickel nitrate and 0.24g of urea and dissolve it in 80ml of distilled water under stirring. After stirring for 20 minutes, pour the solution into a 100ml Teflon liner; put the carbon paper obtained in step 1) vertically Put it into the Teflon liner, then put the liner into the autoclave, heat it to 120℃ in the muffle furnace after sealing, and keep it at this temperature for 16h; after cooling down, take out the carbon paper and find pink The colored solid grows on its surface. Place the carbon paper taken out in a beaker containing 20ml of distilled water for 5 minutes, then rinse it with water and ethanol several times, and dry it overnight in an oven at 80°C;

[0063] 3) Put the dried sample in step 2) in a ...

Embodiment 2

[0068] 1) Put two pieces (3×4cm 2 ) Conductive glass into 0.5MH 2 SO 4 Ultrasound in the solution for 30 minutes, take it out and wash it with ethanol and water several times, and place it in a vacuum drying oven at 30°C to dry;

[0069] 2) Take 0.66g cobalt nitrate, 0.33g nickel nitrate and 0.24g urea and dissolve it in 80ml distilled water under stirring. After stirring for 20 minutes, pour the solution into a 100ml Teflon liner; vertically the conductive glass obtained in step 1) Put it into the previous Teflon liner, then put the liner into the autoclave, heat it to 120℃ in the muffle furnace after sealing, and keep it at this temperature for 16h; after cooling, take out the conductive glass and find pink The colored solid grows on its surface. Place the removed conductive glass in a beaker containing 20ml of distilled water for 5 minutes, then rinse it with water and ethanol several times, and dry it overnight in an oven at 80°C;

[0070] 3) Put the dried sample in step 2) in ...

Embodiment 3

[0074] 1) Put two pieces (3×4cm 2 ) Carbon paper into 0.5MH 2 SO 4 Ultrasound in the solution for 30 minutes, take it out and wash it with ethanol and water several times, and place it in a vacuum drying oven at 30°C to dry;

[0075] 2) Dissolve 0.43g cobalt nitrate, 0.16g nickel nitrate and 0.33g urea in 80ml distilled water under stirring. After stirring for 20 minutes, pour the solution into a 100ml Teflon liner; vertically the carbon paper obtained in step 1) Put it into the previous Teflon liner, then put the liner into the autoclave, heat it to 120℃ in the muffle furnace after sealing, and keep it at this temperature for 16h; after cooling, take out the carbon paper and find pink The colored solid grows on its surface. Place the carbon paper taken out in a beaker containing 20ml of distilled water for 5 minutes, then rinse it with water and ethanol several times, and dry it overnight in an oven at 80°C;

[0076] 3) Put the dried sample in step 2) in a muffle furnace and annea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com