Multifunctional material PANI-CMC-Fe3O4 and application of multifunctional material PANI-CMC-Fe3O4 to treatment of printing and dyeing wastewater

A pani-cmc-fe3o4, multi-functional technology, applied in the preparation and application of multi-functional water treatment materials, can solve the problems of limited application, and achieve the effect of mild reaction conditions and good adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

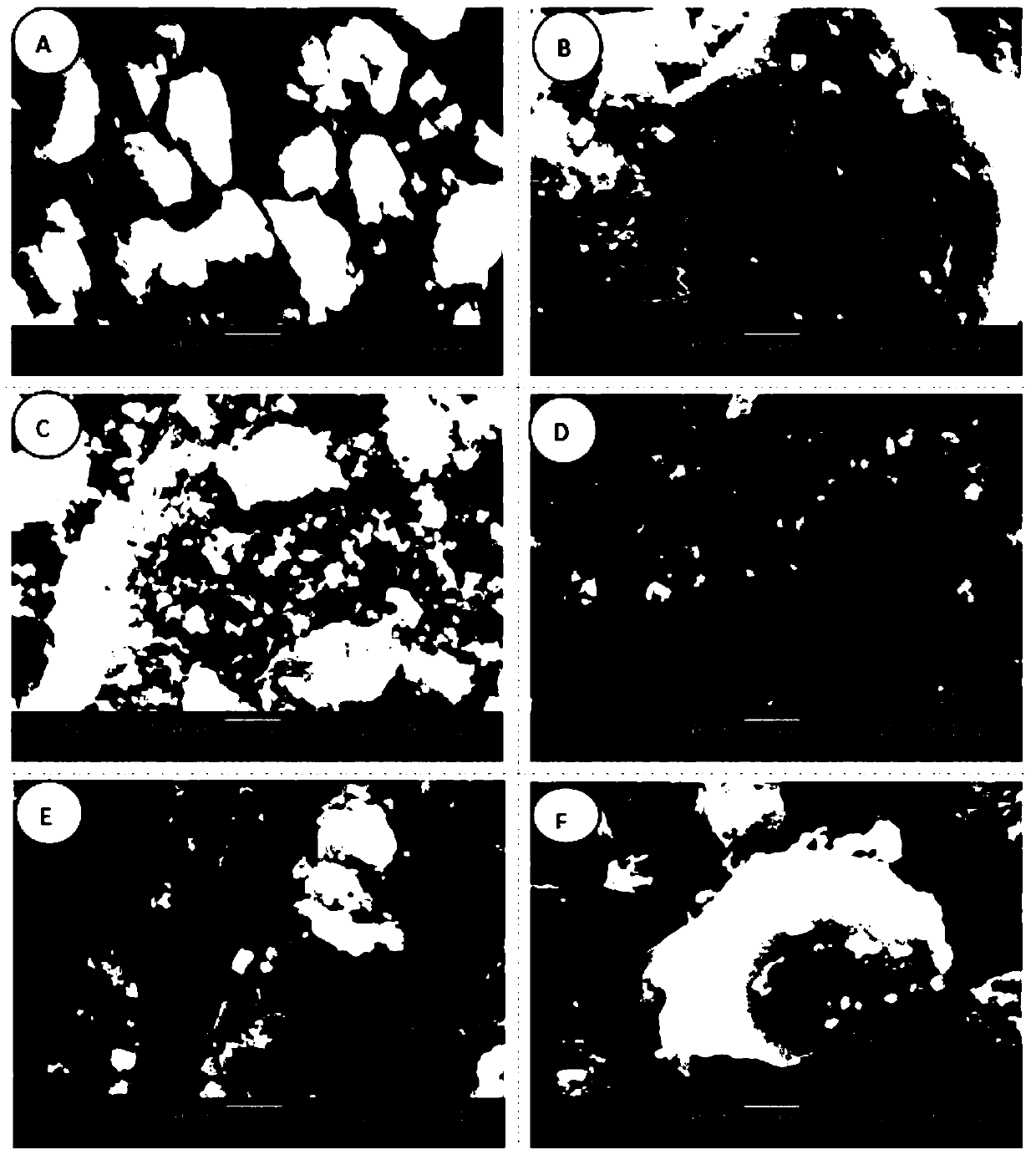

Image

Examples

Embodiment 1

[0019] In the citric acid-sodium citrate buffer solution with pH=4.00, add 0.500g of CMC, after it forms a uniform dispersion system, add 0.2g, 0.5g and 0.8g of self-made magnetic Fe 3 o 4 , and mix well. Afterwards, 1 mL of purified aniline and 1 mL of 10 mg / L Hemin were added to the reaction system, and mixed uniformly. Place each reaction system at 25°C and react on a 150r / min shaker, and add 0.2mL of 30% H to each system every 15min 2 o 2 , a total of 7 times. Last join H 2 o 2 Afterwards, let it react for 0.5 h, add 25 mL of 37% HCl to the reaction system, maintain the shaking reaction for 0.5 h, and let it stand for 16 h. After the reaction is finished, the product is washed successively with deionized water and absolute ethanol, and the product obtained by centrifugation is dried at 60° C. and ground for later use. The products obtained are marked as A, B and C, and the product masses are 1.5041g, 1.5816g and 1.7248g in turn.

[0020] At the same time, using the...

Embodiment 2

[0025] Using 20mg / L anionic dye methyl orange solution as a simulated printing and dyeing wastewater, the static adsorption effect of different dosages of multifunctional materials was evaluated under the conditions of 25°C and 150r / min.

[0026] For the material A prepared in Example 1, carry out the adsorption reaction according to the dosage of 0.05, 0.10, 0.20, 0.30, 0.40 and 0.50g / L respectively, take samples respectively after 60min, measure its absorbance at 464nm, and calculate the removal rate, They are 17.38%, 35.82%, 55.49%, 70.05%, 78.81% and 82.85%, respectively.

[0027] The results showed that the prepared multifunctional material PANI-CMC-Fe 3 o 4 Shows good adsorption properties for dyes.

Embodiment 3

[0029] Using 20mg / L anionic dye methyl orange solution as the simulated printing and dyeing wastewater, the static adsorption effect of multifunctional materials was evaluated under the conditions of 25°C and 150r / min.

[0030] For the materials B, D, E, and F prepared in Example 1, the dosage of 0.5g / L was used, and when the adsorption time was 10min, 30min, and 60min, respectively, samples were taken to measure their absorbance at 464nm, and the different materials at different times were calculated. The removal rate of the dye.

[0031] The removal rate of sample F (pure PANI) reached 62.29%, 74.40% and 85.56% at 10 min, 30 min and 60 min, respectively.

[0032] The removal rate of sample E (PANI-CMC) reached 84.14%, 90.07% and 93.87% at 10min, 30min and 60min, respectively.

[0033] Sample D (PANI-Fe3 o 4 ) at 10min, 30min and 60min, the removal rate reached 57.15%, 66.35% and 86.57% decolorization rate respectively.

[0034] Sample B (PANI-CMC-Fe 3 o 4 ) at 10min, 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com