Environmentally friendly liquid-supported carbon dioxide separation membrane

A carbon dioxide and separation membrane technology, applied in separation methods, semi-permeable membrane separation, dispersed particle separation, etc., can solve the problem of low selectivity, and achieve the effects of low preparation cost, low price and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

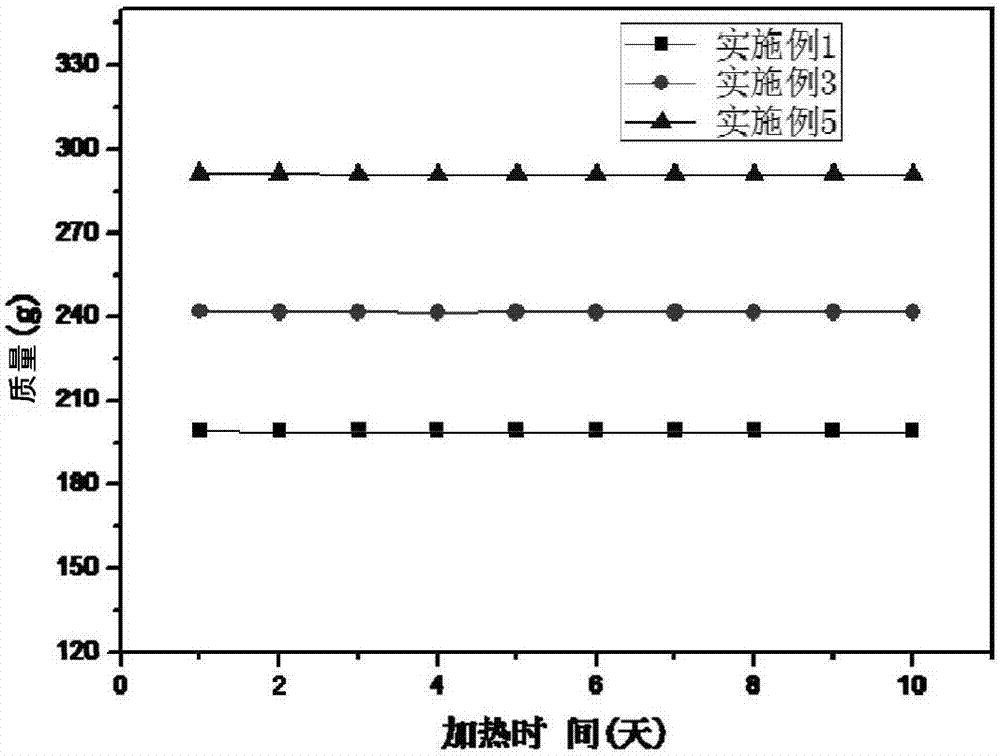

Embodiment 1

[0040] The main components of the environmentally friendly liquid-supported carbon dioxide separation membrane prepared in this example are polyethylene polyamine and polyvinyl alcohol, and the preparation method is as follows:

[0041] Step 1: Take 5g of polyethylene polyamine and 20g of polyvinyl alcohol as the main solute of the separation membrane.

[0042] Step 2: Take 225g of water as a solvent, heat it to 90°C, add polyvinyl alcohol and polyethylene polyamine successively, stir and dissolve, and form a separation membrane casting solution.

[0043] Step 3: Pour the solution evenly on the substrate, and scrape it into a 200 μm wet film with a film scraper.

[0044] Step 4: Put the substrate into a 120° C. constant-temperature drying oven for 3 hours of heat treatment.

[0045] Step 5: Take out the substrate, and after it cools down, remove the film from the substrate, that is, a film with a mass ratio of polyethylene polyamine to polyvinyl alcohol of 1:4 and a thickness...

Embodiment 2

[0047] The main components of the environmentally friendly liquid-supported carbon dioxide separation membrane prepared in this example are polyethylene polyamine and polyvinyl alcohol, and the preparation method is as follows:

[0048] Step 1: Take 5g of polyethylene polyamine and 10g of polyvinyl alcohol as the main solute of the separation membrane.

[0049] Step 2: Take 35g of water as a solvent, heat it to 95°C, add polyvinyl alcohol and polyethylene polyamine successively, stir and dissolve, and form a separation membrane casting solution.

[0050] Step 3: Pour the solution evenly on the substrate, and scrape it into a 40 μm wet film with a film scraper.

[0051] Step 4: Put the substrate into a constant temperature drying oven at 80° C. for 5 hours of heat treatment.

[0052] Step 5: Take out the substrate, and after it cools down, remove the film from the substrate, that is, a film with a mass ratio of polyvinyl polyamine to polyvinyl alcohol of 1:2 and a thickness of...

Embodiment 3

[0054] The main components of the environmentally friendly liquid-supported carbon dioxide separation membrane prepared in this example are polyethylene polyamine and polyvinyl alcohol, and the preparation method is as follows:

[0055] Step 1: Take 5g of polyethylene polyamine and 15g of polyvinyl alcohol as the main solute of the separation membrane.

[0056] Step 2: Take 100 g of water as a solvent, heat it to 93° C., add polyvinyl alcohol and polyethylene polyamine successively, stir and dissolve, and form a separation membrane casting solution.

[0057] Step 3: Pour the solution evenly on the substrate, and scrape it into a 160 μm wet film with a film scraper.

[0058] Step 4: Put the substrate into a constant temperature drying oven at 100° C. for 3 hours of heat treatment.

[0059] Step 5: Take out the substrate, and after it cools down, remove the film from the substrate, that is, a film with a thickness of 33 μm and a mass ratio of polyethylene polyamine to polyvinyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com