Method for preparing flavored product from yellow water and liquor-making microbes

A technology of microorganisms and flavors, applied in the field of pickled and fermented foods, can solve the problems of not using yellow water, etc., and achieve the effect of increasing the utilization value and improving the delicious flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1. Raw materials

[0026] Loach: Fresh small loach sold in the market after 4 months of breeding. The flour was commercially available barley flour. Saccharomyces monchioccus, Hansenula, Candida, Saccharomyces cerevisiae, Saccharomyces cerevisiae, Bacillus licheniformis, Saccharomyces rutheli and other strains were purchased from the China Type Culture Collection. Corn flour is commercially available corn flour. The chili sauce is a freshly available chili powder sauce from the market. Yellow water is the yellow water produced in the production process of Qingxiang Xiaoqu liquor. The wort medium was purchased from Shanghai Yiji Industrial Co., Ltd.

[0027] 2. Fermentation and brewing

[0028] 2.1 Pretreatment of loach

[0029] The loach was cultured in tap water for 2 days, and then changed the water; cultured for another 2 days, and continued to change the water; cultured for another day, without feeding during the culture. Open the belly of the loach, remove t...

Embodiment 2

[0041] Comparative test 1: except that the loach is selected to raise the loach sold in the market for one and a half years, other operations are the same as in Example 2, and the final product quality obtained is shown in Table 2.

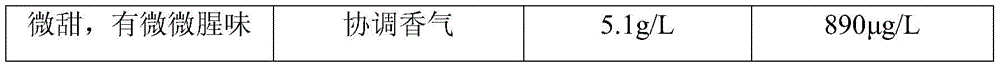

[0042] Table 2 Product Quality

[0043]

[0044]

[0045] Comparative test 2: Except for replacing yellow water with tap water in the loach pretreatment step, other operations are the same as in Example 1, and the final product quality is shown in Table 3.

[0046] Table 3 Product Quality

[0047] Product taste

Product aroma

total ester content

Pyrazine content

slightly sweet, astringent

Harmonious aroma, slight aroma

1.8g / L

820μg / L

[0048] Comparative test 3: Except that only corn flour was added in the three inoculation fermentation, and the chili sauce was not inserted into Bacillus licheniformis, other operations were the same as those in Example 1, and the final product quality was shown ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com