Vegetable greenhouse capable of melting snow

A vegetable greenhouse and greenhouse technology, applied in the agricultural field, can solve the problems of poor load-bearing capacity of plastic films, economic losses of vegetable farmers, collapse of vegetable greenhouses, etc., and achieve the effects of strengthening thermal insulation, improving thermal insulation, and reducing heat attenuation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described through specific embodiments below in conjunction with the accompanying drawings.

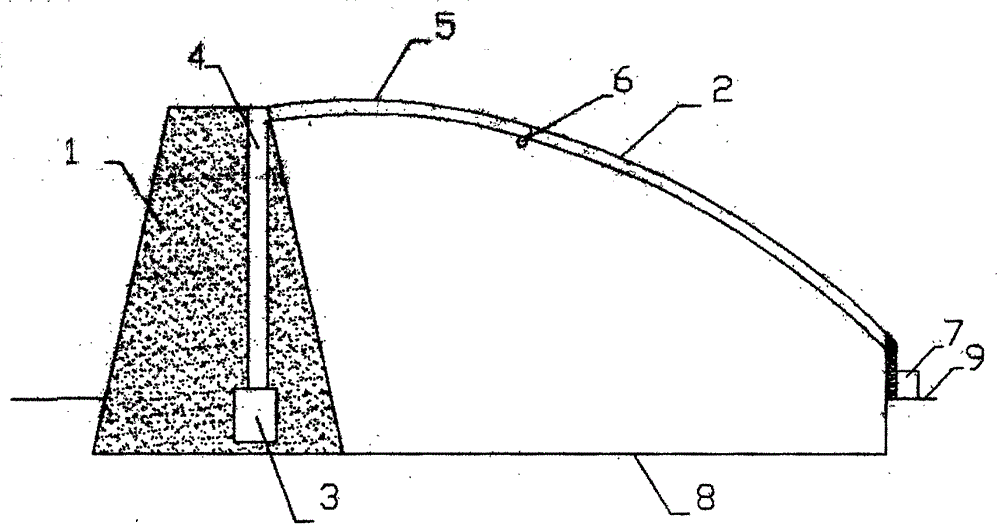

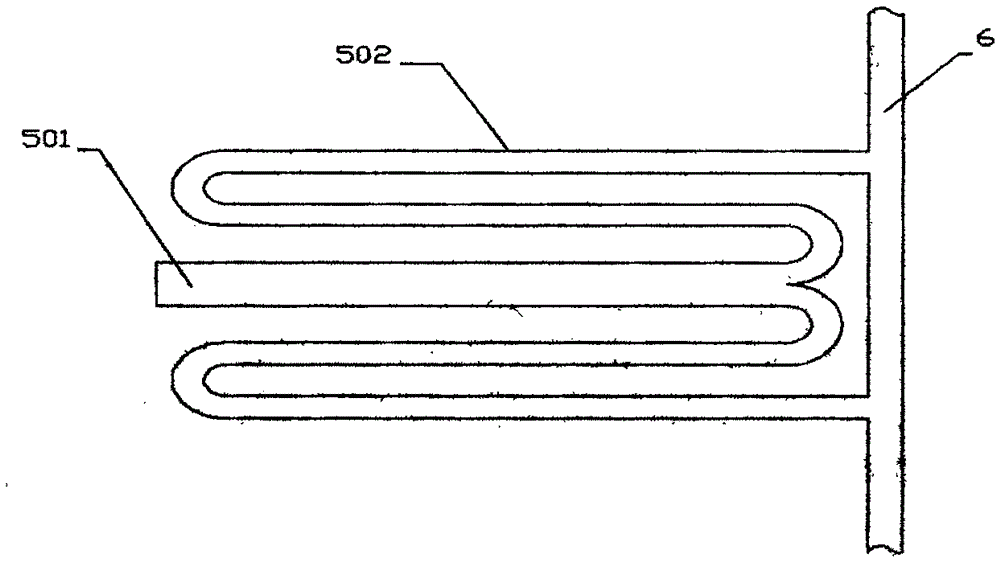

[0016] As shown in the figure, a kind of snow-melting vegetable greenhouse adopts a semi-underground type, that is, an earth pit is excavated on the ground, and the vegetable planting surface is in the earth pit. Pillars and arches for supporting the plastic film are fixed between the earth wall and the brick wall, and the plastic film is fixed on the arch, and gables and buffer rooms for heat preservation are built at both ends of the pit, and A heating furnace is set in the buffer room, and a flue is built in the earth wall. The flue includes a horizontal flue and a vertical flue arranged on the horizontal flue. The length direction extends to one end of the earth wall, and communicates with the smoke outlet of the heating furnace through the fan. The vertical flue is evenly arranged on the horizontal flue, and passes through the earth wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com