Driving method for led driver

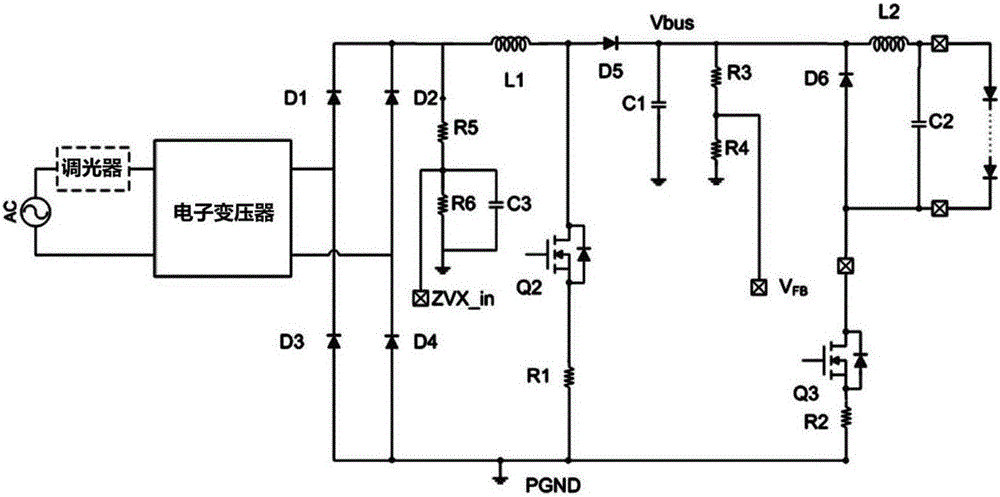

An LED driver and driving method technology, applied in lighting devices, light sources, electrical components, etc., can solve the problems of DC bus overvoltage, damage to the system, system damage, etc., to achieve the effect of safe startup and avoid system abnormalities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

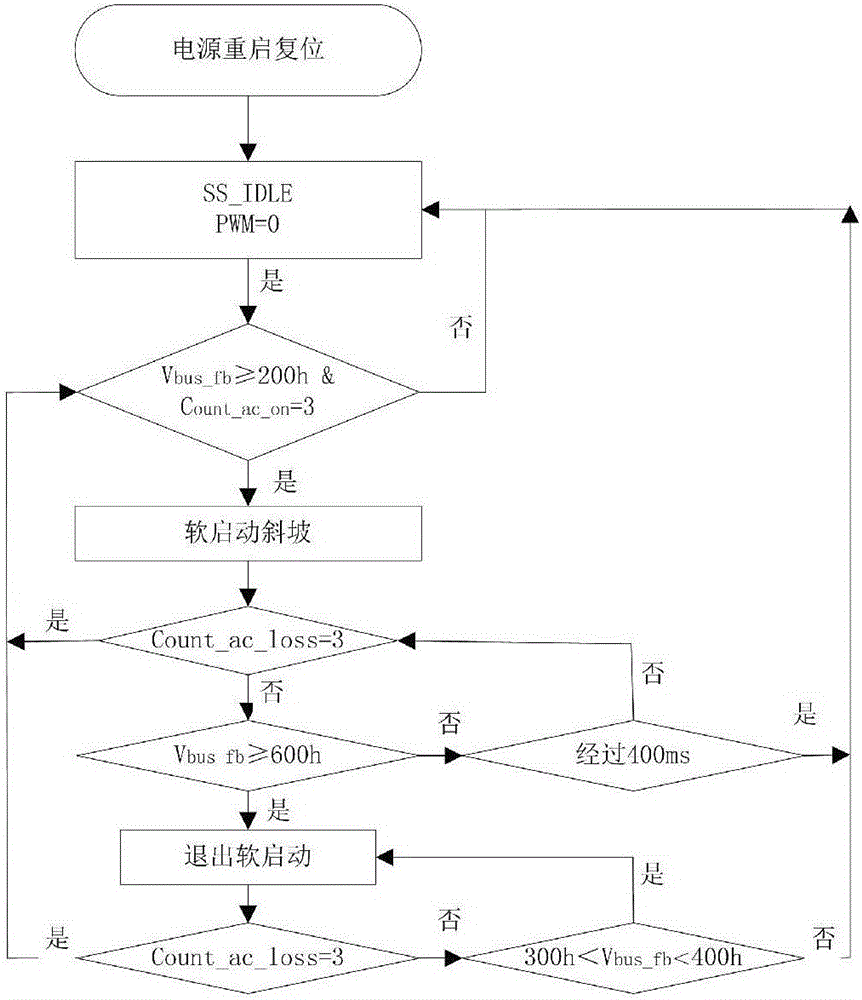

[0029] In order to solve the above problems, the applicant has carried out in-depth research, the research process is as described in the background technology, and will not be described here. Based on the above research, the applicant proposes the following solutions. The method comprises the steps of:

[0030] Detect whether there is an AC input signal, and if there is an AC input signal, start the ramp up of the PWM;

[0031] Detect whether the bus voltage feedback signal is greater than a predetermined value, if greater than the predetermined value, then end the start-up process.

[0032] The above method can effectively solve the problems existing in the prior art. When there is no AC input signal, the soft start program does not work, so the situation mentioned in the background art does not occur. It is safer to start and can avoid abnormal situations.

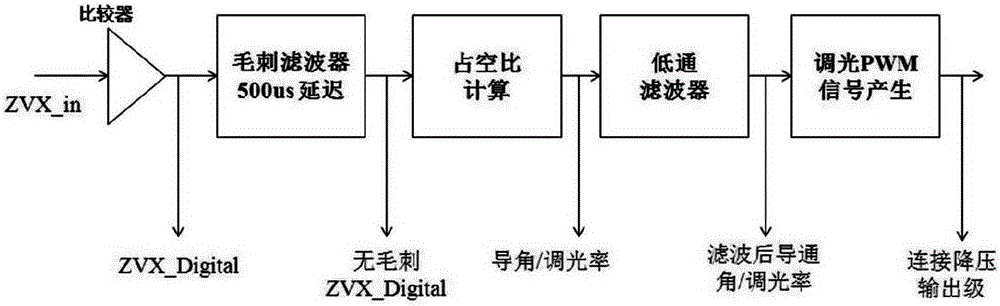

[0033] In a further embodiment, whether there is an AC input signal is judged based on the number of rising edges ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com