Circular flow air cooling heat radiation device of power batteries

A power battery and cooling device technology, applied in the direction of secondary batteries, circuits, electrical components, etc., can solve the problems of uneven temperature distribution, unguaranteed heat dissipation effect of the battery pack, high local temperature of the battery pack, etc., and achieve good temperature consistency performance, good heat dissipation effect, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The purpose of the present invention will be further described in detail below through specific examples. The examples cannot be repeated here, but the implementation of the present invention is not limited to the following examples.

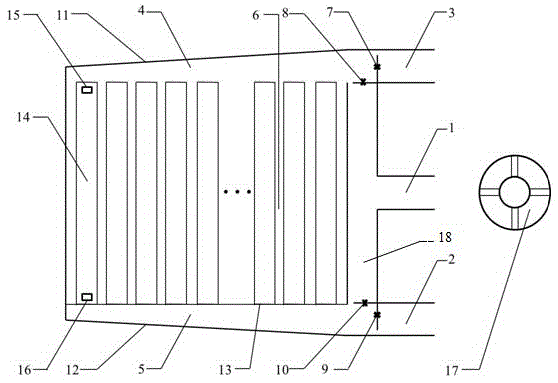

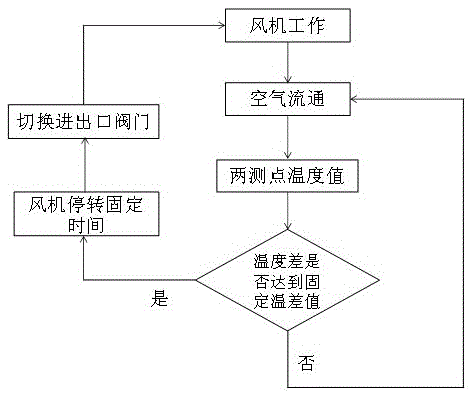

[0020] Such as figure 1 As shown, a power battery circulating air cooling device includes a battery box with an L-shaped support plate 13, a stepping fan 17, a temperature sensor for monitoring the temperature difference of each part of the power battery 14, and a control device. One side of the battery box is sequentially provided with a top air outlet 3 for discharging the air in the battery box, an air inlet 1 for inputting air to the battery box through a stepping fan 17, and an air inlet 1 for discharging air from the battery box. The bottom air outlet 2, the top air outlet 3, the bottom air outlet 2, and the air inlet channel in the battery box are all provided with electric control valves, and the control device is connected with the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com