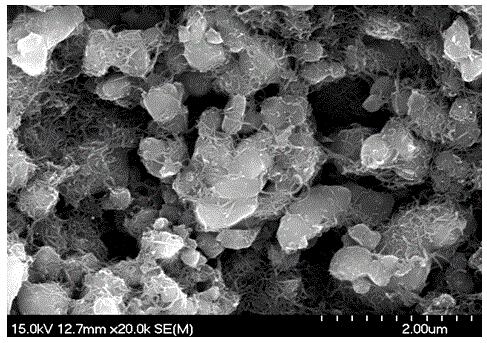

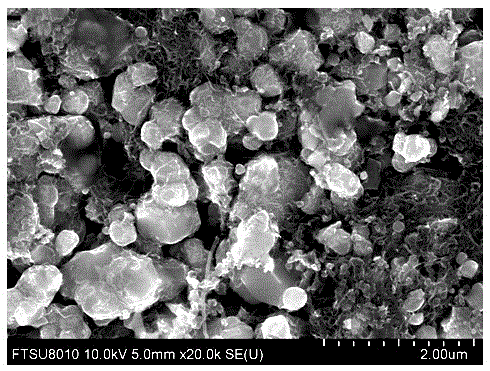

CNT-containing lithium ion battery waterborne positive electrode paste and preparation method therefor

A cathode slurry, lithium battery technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as affecting the health of workers in the production workshop, large specific surface area of CNTs, and high toxicity on the production site, so as to avoid environmental pollution. and poor safety, small battery polarization, and the effect of reducing material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Add 25kg of carbon nanotube dispersion, 3kg of conductive agent carbon black and 10% of 100kg of deionized water into a double planetary mixer and stir for 20 minutes. The dispersion speed of the double planetary mixer is 500±20rpm, revolution 20± 1 rpm;

[0031] (2) Add 3 / 5 of 70kg of lithium iron phosphate to the mixture in (1), stir for 20 minutes, then add the remaining lithium iron phosphate and 10% of deionized water and stir for 30 minutes;

[0032] (3) Add 2kg of water-based binder LA132 to the mixed material in (2). The double planetary mixer stirs at a dispersion speed of 500rpm and a revolution of 2rpm for 5min, then at a dispersion speed of 1000rpm and a revolution of 20rpm for 30min, and finally at a dispersion speed of Stir at 4500rpm and revolution at 35rpm for 4h;

[0033] (4) Add the remaining deionized water to the mixed material in (3), so that the solid content in the material is 50%, and stir for 40 minutes at a dispersion speed of 4500±20rpm a...

Embodiment 2

[0041] (1) Add 30kg of carbon nanotube dispersion liquid, 2kg of conductive agent (acetylene black, carbon black mass ratio is 1:1) and 20% of 120kg of deionized water into a double planetary mixer and stir for 40min. The double planetary mixer The dispersion speed is 500±20rpm, and the revolution is 20±1rpm;

[0042] (2) Add 3 / 5 of 64kg lithium iron phosphate to the mixture in (1), stir for 40 minutes, then add the remaining lithium iron phosphate and 5% of deionized water and stir for 10 minutes;

[0043] (3) Add 4kg of water-based binder LA135 to the mixed material in (2). The double planetary mixer stirs at a dispersion speed of 500rpm and a revolution of 2rpm for 20min, then at a dispersion speed of 1000rpm and a revolution of 20rpm for 30min, and finally at a dispersion speed of Stir at 4500rpm and revolution at 35rpm for 4h;

[0044] (4) Add the remaining deionized water to the mixed material in (3), so that the solid content of the material is 60%, and stir for 40 min...

Embodiment 3

[0047] (1) Add 28kg of carbon nanotube dispersion, 1kg of conductive agent Ketjen black and 15% of 110kg of deionized water into a double planetary mixer and stir for 30 minutes. The dispersion speed of the double planetary mixer is 500±20rpm, revolution 20 ±1rpm;

[0048] (2) Add 3 / 5 of the 70kg lithium iron phosphate to the mixture in (1), stir for 30 minutes, then add the remaining lithium iron phosphate and 8% in deionized water and stir for 20 minutes;

[0049] (3) Add 1kg of water-based binder LA133 to the mixed material in (2), stir with the double planetary mixer at a dispersion speed of 500rpm and a revolution of 2rpm for 10min, then stir at a dispersion speed of 1000rpm and a revolution of 20rpm for 30min, and finally Stir at 4500rpm, revolution at 35rpm for 4h;

[0050] (4) Add the remaining deionized water to the mixed material in (3), so that the solid content in the material is 55%, and stir for 30 minutes at a dispersion speed of 4500±20rpm and a revolution of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com