A kind of electrolytic solution for aluminum electrolytic capacitor with high conductance and long life in anhydrous system and preparation method thereof

A technology of aluminum electrolytic capacitor and anhydrous system, which is applied in the field of electrolyte, can solve problems such as increased vapor pressure of electrolyte, early failure of capacitor, failure of capacitor opening valve, etc., and achieves low production cost, large ripple current and high production efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

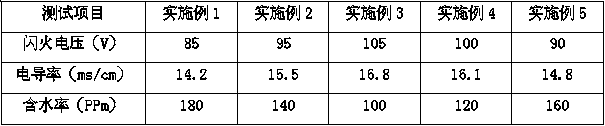

Examples

Embodiment 1

[0055] An electrolyte solution for an anhydrous system high-conductivity and long-life aluminum electrolytic capacitor, which consists of the following raw materials in parts by weight:

[0056] 30 parts of solute

[0057] Additive 0.5 parts

[0058] 50 parts of organic solvent;

[0059] The solute is a mixture of 1.3-dimethylimidazole and dimethyl phosphate in a molar ratio of 0.8:0.8.

[0060] The additive is phosphotungstic acid.

[0061] The organic solvent is γ-hydroxybutyrolactone.

[0062] A method for preparing an electrolyte solution for aluminum electrolytic capacitors with high conductivity and long life in an anhydrous system, mixing solutes, additives and organic solvents, stirring evenly, heating to 85°C, and vacuuming for 3.5 hours to prepare an anhydrous system with high conductivity and long life Electrolyte for aluminum electrolytic capacitors.

Embodiment 2

[0064] An electrolyte solution for an anhydrous system high-conductivity and long-life aluminum electrolytic capacitor, which consists of the following raw materials in parts by weight:

[0065] 35 parts of solute

[0066] Additive 0.8 parts

[0067] 55 parts of organic solvent;

[0068] The solute is a mixture of 1.3-dimethylimidazole and dimethyl phosphate in a molar ratio of 0.9:1.

[0069] The additive is phosphotungstic acid.

[0070] The organic solvent is γ-hydroxybutyrolactone.

[0071] A method for preparing an electrolyte solution for aluminum electrolytic capacitors with high conductivity and long life in an anhydrous system, mixing solutes, additives and organic solvents, stirring evenly, heating to 88°C, and vacuuming for 3.2 hours to prepare an anhydrous system with high conductivity and long life Electrolyte for aluminum electrolytic capacitors.

Embodiment 3

[0073] An electrolyte solution for an anhydrous system high-conductivity and long-life aluminum electrolytic capacitor, which consists of the following raw materials in parts by weight:

[0074] Solute 40 parts

[0075] Additive 1 part

[0076] 59 parts of organic solvent;

[0077] The solute is a mixture of 1.3-dimethylimidazole and dimethyl phosphate in a molar ratio of 1:1.

[0078] The additive is phosphotungstic acid.

[0079] The organic solvent is γ-hydroxybutyrolactone.

[0080] A method for preparing an electrolyte solution for an anhydrous system high-conductivity and long-life aluminum electrolytic capacitor, mixing solutes, additives and organic solvents, stirring evenly, heating to 90°C, and vacuuming for 3 hours to prepare anhydrous system high-conductivity and long-life aluminum Electrolyte for electrolytic capacitors.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com