A cvt capacitance online monitoring method based on cvt secondary voltage monitoring

A technology of secondary voltage and reference voltage, applied in measuring devices, measuring electrical variables, instruments, etc., can solve problems such as failure to find capacitor breakdown, high requirements for instrument capacity, and inability to detect excessive ratio error. Unable to monitor the breakdown of a few capacitors, good anti-interference performance, saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

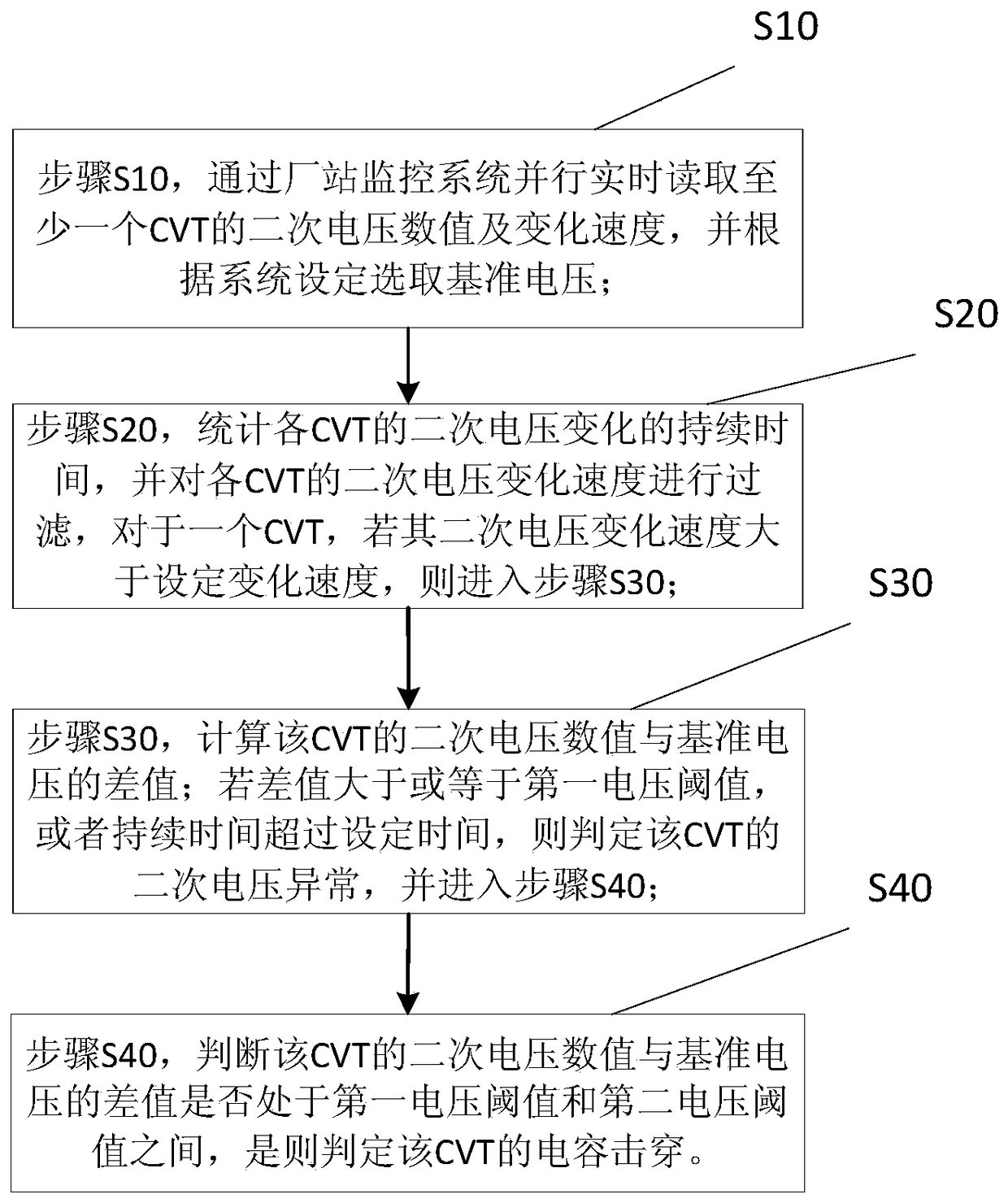

[0026] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings and embodiments. Apparently, the described embodiments are only some of the embodiments of the present invention, not all of them.

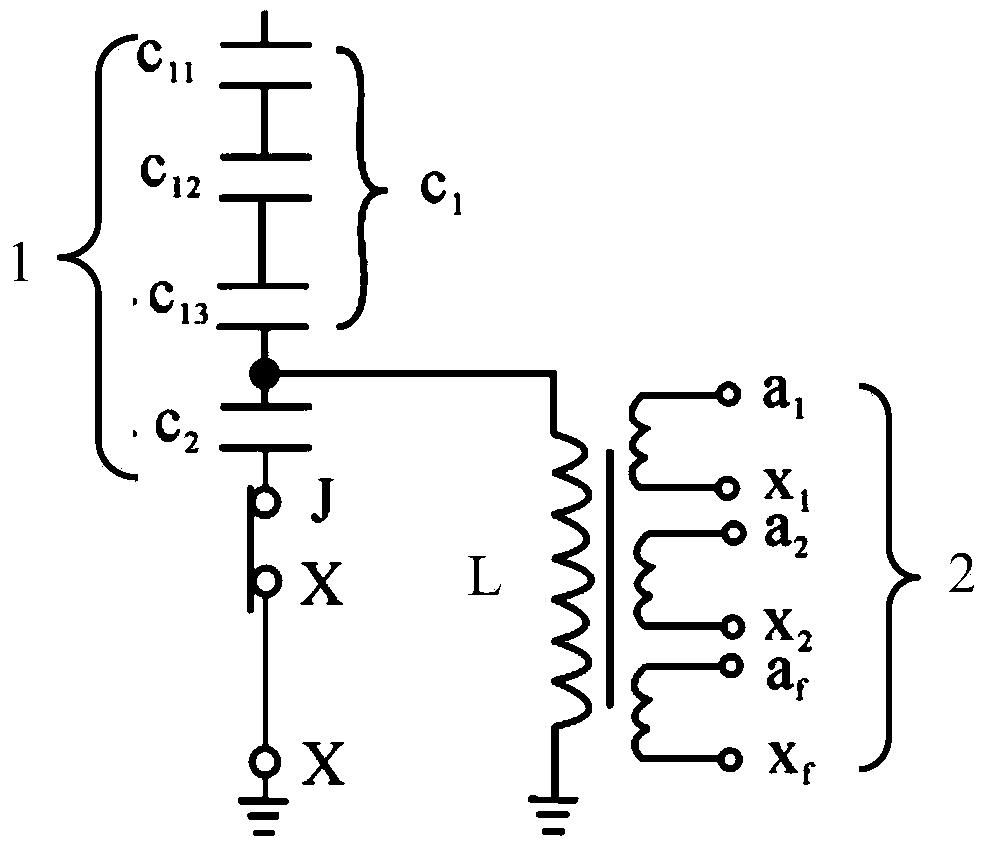

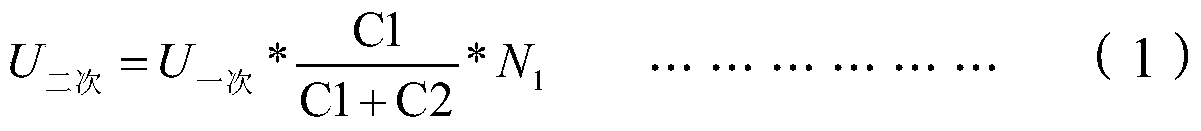

[0027] see figure 1 , is the structural principle diagram of the CVT. The CVT is mainly composed of the capacitive voltage divider 1 and the electromagnetic part 2 in structure, and the capacitive voltage divider C1 and C2 are two parts. For example, a CVT is composed of three porcelain bushings in appearance, C11 and C12 are in the upper and middle porcelain bushings respectively, and C13 and C2 are in the lower porcelain bushing and are connected together by the flange and the electromagnetic part. In this embodiment, the CVT takes the following parameters as an example: There are 154 elements in the capacitor of the ceramic sleeve, among which C13 has 130 elements, and C2 has 24 elements. No...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com