Positioning device and positioning method of partial discharge source of electrical device

A technology of electrical equipment and positioning devices, which is applied in the direction of measuring devices, measuring electricity, and measuring electrical variables, etc., can solve problems such as large noise influence, low signal-to-noise ratio, and demanding manufacturing process requirements, and achieve high signal-to-noise ratio advantages and high The effect of resolving power and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0036] The invention includes a differential pressure vector sensor, a high-frequency carrier communication module and an analyzing device. The differential pressure vector sensor is set in the insulating oil of electrical equipment to collect discharge information; the high-frequency carrier communication module is used to send the information transmitted by the differential pressure vector sensor to the analysis device; the analysis device is set in the control room for The information collected by the differential pressure vector sensor is analyzed to obtain the specific location of the partial discharge source.

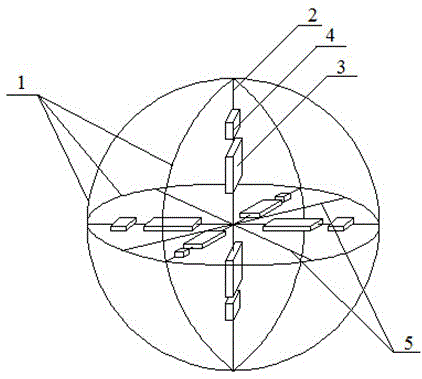

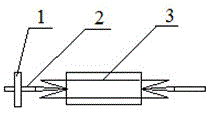

[0037] Differential pressure vector sensor, including a spherical structure, six double-stacked curved piezoelectric ceramic sensors 3, six data acquisition modules 4, and connecting rods for fixing the double-stacked cur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com