Continuous high pressure oxidation experimental device and method for natural gas hydrate gas release

An experimental device, hydrate technology, applied in the ecological environment, oil and gas fields, to achieve the effect of simple instrument structure and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

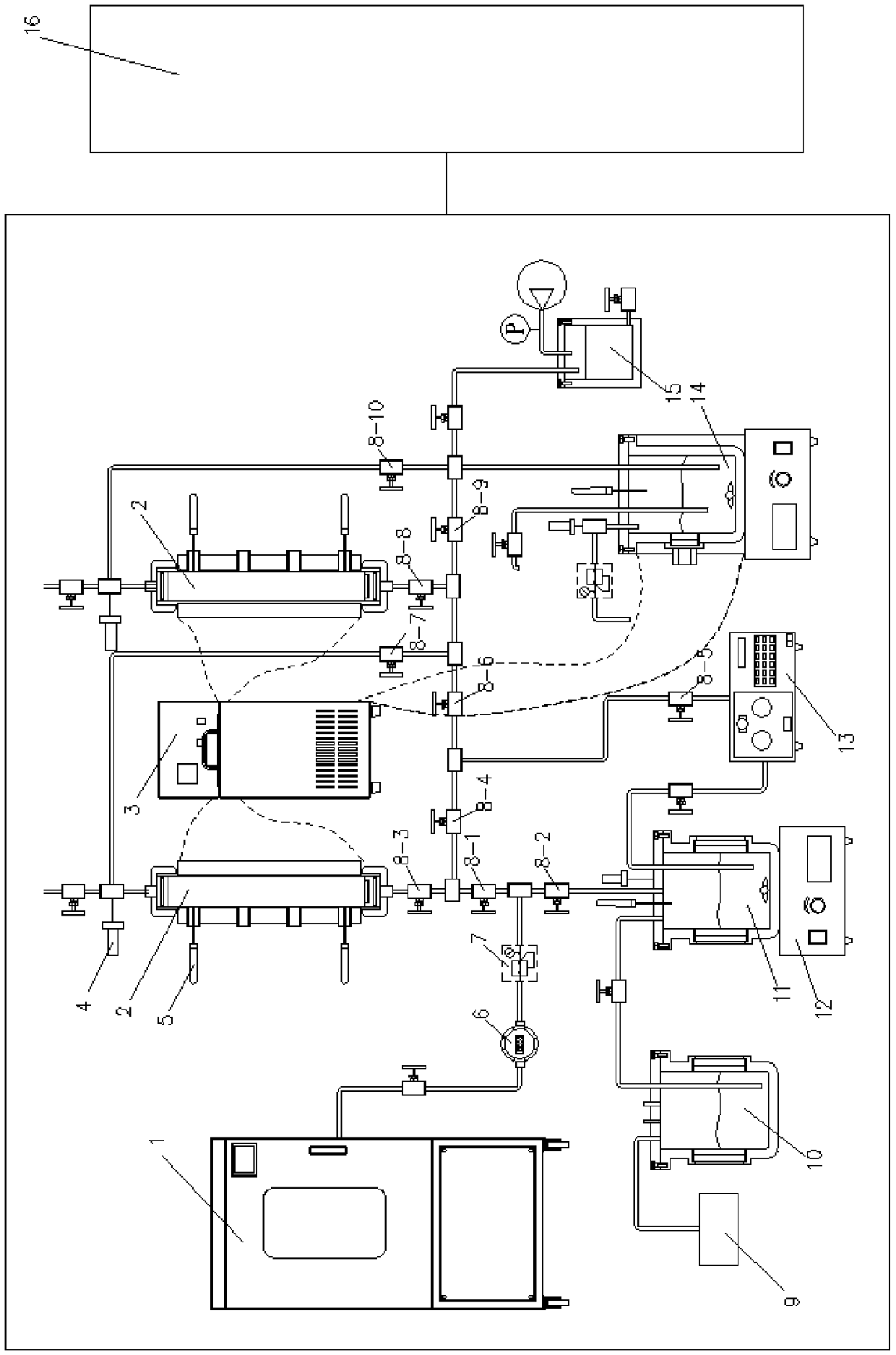

[0031] The present invention will be further explained below in conjunction with accompanying drawing:

[0032] A continuous high-pressure oxidation experimental device for releasing gas from natural gas hydrate, which mainly includes a generation-decomposition unit 1, a gas continuous high-pressure oxidation unit, and a data acquisition and processing unit 16, and the formation-decomposition unit 1 and the gas continuous high-pressure oxidation unit pass through The gas mass flowmeter 6 is connected to the precision pressure regulating valve 7; wherein,

[0033] (1) Generation-decomposition unit 1: comprising a high-pressure reaction kettle placed in a low-temperature constant temperature box, the outside of the kettle body is equipped with a water bath jacket, and the bottom of the kettle body is provided with a magnetic stirrer 12;

[0034] (2) Gas continuous high-pressure oxidation unit: comprising a solid system, a liquid system, a constant temperature water bath 3 and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com