Four-point cylindricity measurement method based on singularity rate analysis

A measurement method and cylindricity technology, applied in the field of four-point cylindricity measurement based on singularity rate analysis, can solve problems such as restricting the anti-interference ability of the measurement system and increasing error sources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

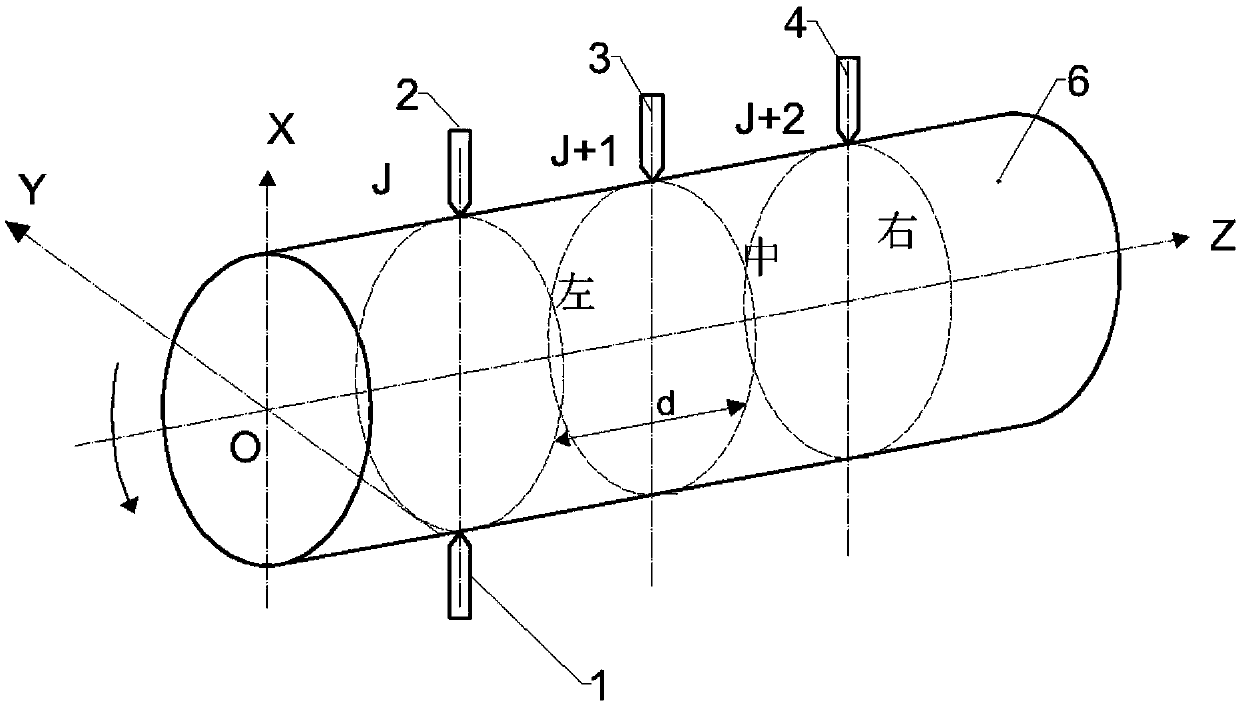

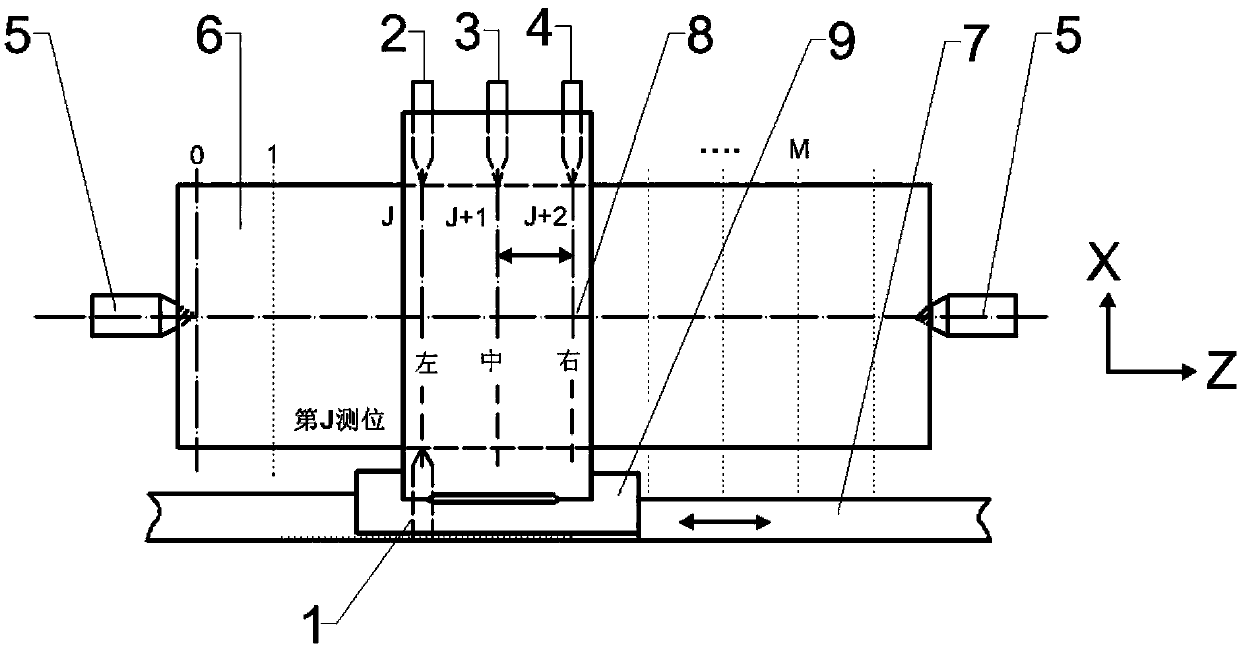

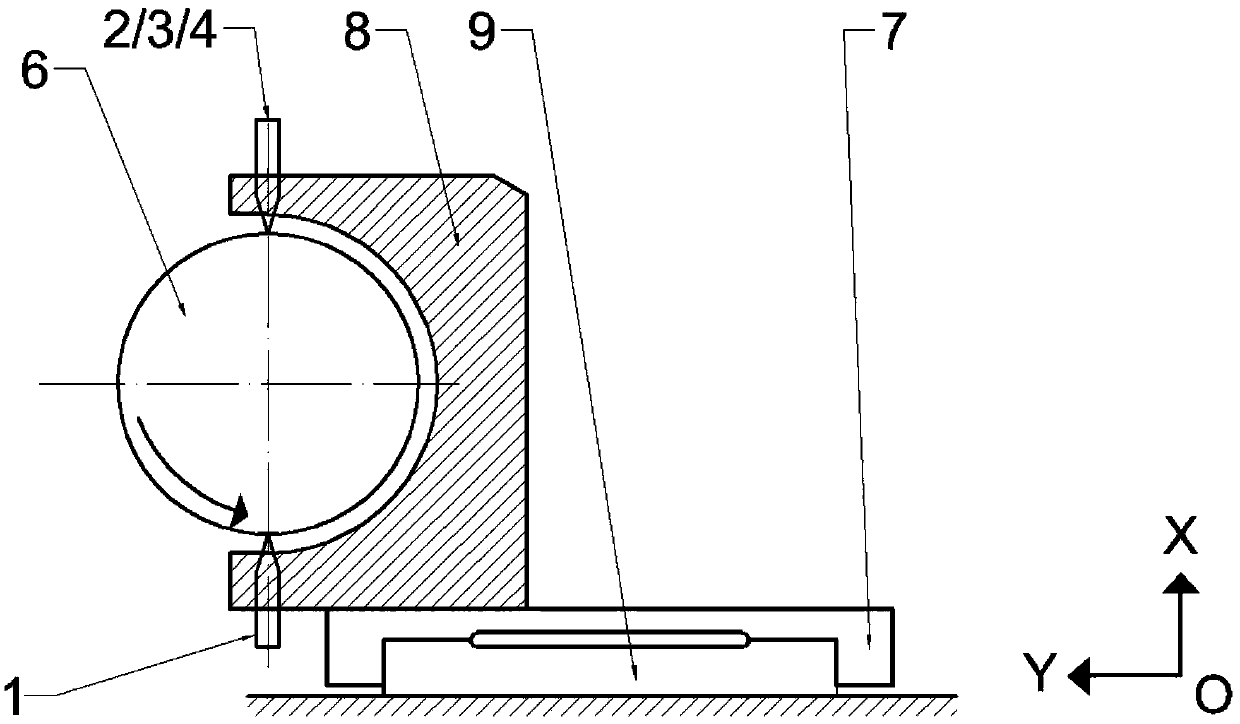

[0052] In this example, if figure 2 As shown, a four-point cylindricity measurement method based on singularity analysis, the measurement frame (8) can move in the Y-Z direction under the joint support of the Z guide rail (7) and the Y guide rail (9); the supporting shaft system (5 ) supports and drives the object under test (6) to rotate; the Z guide rail (7) is parallel to the axial direction of the object under test (6); at the beginning of the measurement, the measuring frame (8) is approached along the Y direction under the support of the Y guide rail (9) The measured object 6 moves into the position measurement along the Z direction under the support of the Z guide rail (7), and the moving step distance of the measuring frame (8) along the Z direction is d; The multi-turn measurement signals collected are obtained from the mixed signals of the measured cylindrical cross-section shape, the shaft runout and the linear error motion of the measuring frame. Carry out singul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com