Apparatus and method for generating and injecting diagnostic tracers in plif flow field

A tracer and flow field technology, applied in the direction of measuring devices, instruments, fluorescence/phosphorescence, etc., can solve the problems of inability to accurately determine the mixed steam, temperature, air pressure and concentration that affect the accuracy of the experiment, so as to achieve stable temperature and flow, and realize Precise control, scientific and reasonable operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

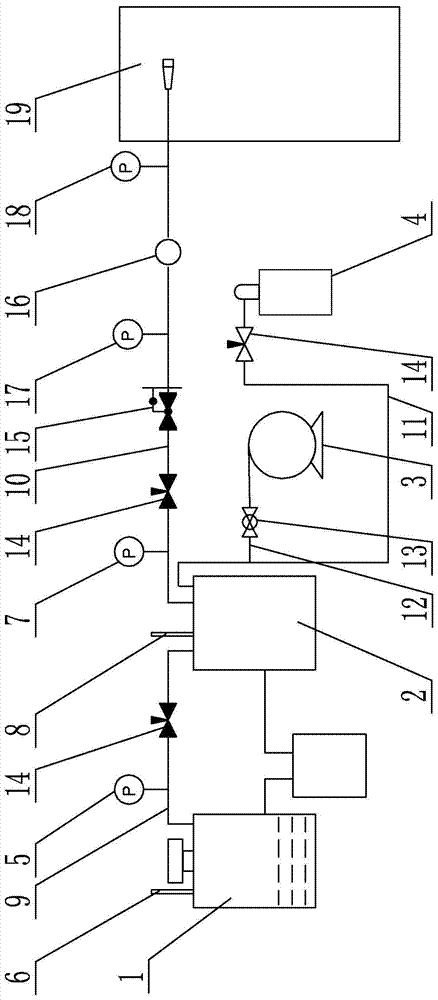

[0021] Specific implementation mode one: combine figure 1 Describe this embodiment, the device in this embodiment includes a generator tank 1, a gas mixing tank 2, a vacuum pump 3, a dilution gas bottle 4, a first pressure gauge 5, a first thermocouple 6, a second pressure gauge 7, a second Thermocouple 8, first gas pipeline 9, second gas pipeline 10, third gas pipeline 11, fourth gas pipeline 12, ball valve 13, three needle valves 14, multiple first heating coils and multiple second heating coil;

[0022] The generating tank 1 communicates with the gas mixing tank 2 through the first gas pipeline 9, the generating tank 1 is provided with a first thermocouple 6, and the gas mixing tank 2 is provided with a second thermocouple 8, so The first pressure gauge 5 is installed on the first gas pipeline 9, the gas mixing tank 2 communicates with the dilution gas bottle 4 through the third gas pipeline 11, and the third gas pipeline 11 communicates with a fourth One end of the gas p...

specific Embodiment approach 2

[0026] Specific implementation mode two: combination figure 1 To illustrate this embodiment, in this embodiment, the first gas transmission pipeline 9 , the second gas transmission pipeline 10 and the fourth gas transmission pipeline 12 are all wound with heating coils.

[0027] In this embodiment, the purpose of wrapping the entire gas pipeline with a heating coil is to ensure that the tracer vapor does not liquefy during transportation. Other unmentioned structures and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0028] Specific implementation mode three: combination figure 1 Describe this embodiment. In this embodiment, the device also includes a pressure reducing valve 15, a gas mass flow meter 16, a third pressure gauge 17, and a fourth pressure gauge 18. A pressure reducing valve 15 and a gas mass flow meter 16 are arranged in turn from one end of the tank 2 to the gas outlet end, and a third pressure gauge 17 and a fourth pressure gauge 18 are also installed on the second gas pipeline 10. The pressure gauge 17 is located between the pressure reducing valve 15 and the gas mass flow meter 16, and the fourth pressure gauge 18 is located between the gas mass flow meter 16 and the gas outlet port. In this embodiment, the purpose of connecting the pressure reducing valve 15 and the gas mass flow meter 16 on the gas mixing tank 2 is to control the outflow speed of the mixed gas so as to put it into the experimental field 19 . Other unmentioned structures and connections are the same as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com