Method for verifying urea crystallization of SCR post-treatment system by use of engine pedestal

An engine bench and SCR system technology, applied in the field of urea crystallization engine bench verification of SCR aftertreatment system, can solve the problems of single verification method, inability to reflect actual road conditions, loss of enterprises and users, etc., achieving good repeatability, Convenient post-processing structure improvement and optimization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with specific drawings.

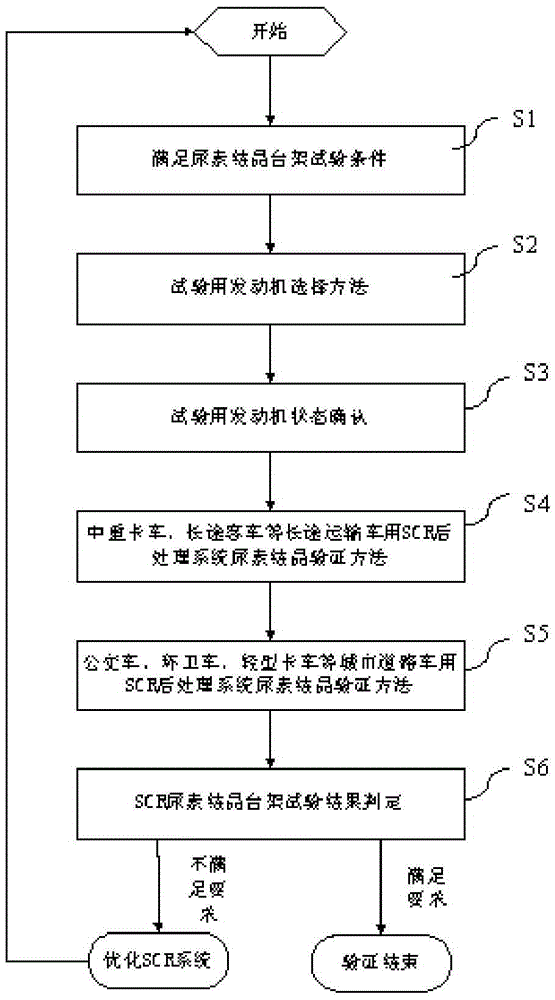

[0028] Such as figure 1 As shown, the SCR post-treatment system urea crystallization engine bench verification method of the present invention specifically includes the following steps:

[0029] Step S1: The technical conditions that need to be met at the beginning of the test, the specific conditions are as follows:

[0030] (1) Before the test, the diesel engine and SCR after-treatment system must complete the emission performance calibration, and the data will not be changed;

[0031] (2) The performance of the SCR injection system meets the requirements and the function is normal;

[0032] (3) The structure of the SCR box meets the requirements of the drawings to ensure that the design is consistent with the production sample;

[0033] (4) The urea solution used in the test meets the technical requirements of the urea solution for vehicles;

[0034] (5) The pipeline co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com