Linear reciprocating-type magnetic tile shape measurement device

A measuring device, a reciprocating technology, applied in the direction of measuring devices, optical devices, instruments, etc., to achieve the effects of improving measurement accuracy, improving product quality, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

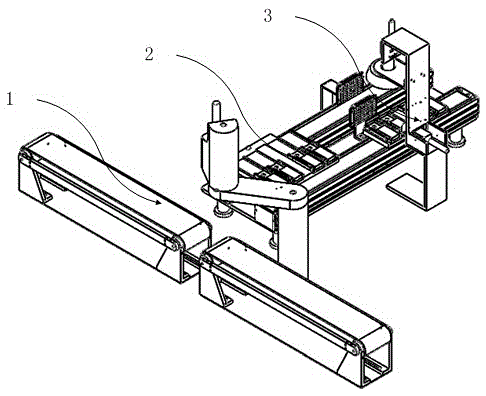

[0036] Embodiment 1: as figure 1 As shown, a linear reciprocating magnetic tile shape measuring device includes a magnetic tile transmission device 1, a magnetic tile positioning device 2, and a measuring device 3;

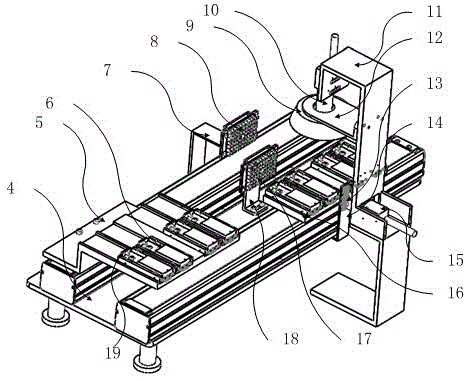

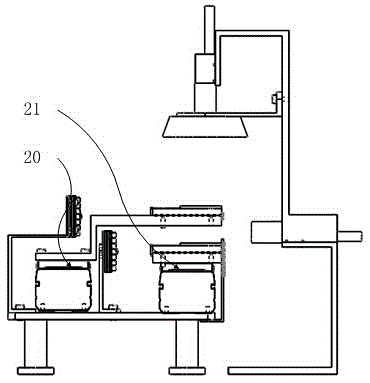

[0037] Such as figure 2 , image 3 As shown, a linear reciprocating magnetic tile shape measuring device, the magnetic tile positioning device 2 includes a rear positioning device mounting plate 5, a measurement positioning device 6, a front positioning device mounting plate 16, a rear module slider 20, a front mold Group slider 21; the rear positioning device mounting plate 5 is installed on the rear module slider 20, the rear module slider 20 is installed on the rear linear module 24, and the front positioning device mounting plate 16 is installed on On the front module slider 21, the front module slider 21 is installed on the front linear module 25, and the measurement positioning device 6 is installed on the rear positioning device mounting plate 5 and the ...

Embodiment 2

[0048] Embodiment 2: as figure 1 As shown, a linear reciprocating magnetic tile shape measuring device includes a magnetic tile transmission device 1, a magnetic tile positioning device 2, and a measuring device 3;

[0049] Such as figure 2 , image 3 As shown, a linear reciprocating magnetic tile shape measuring device, the magnetic tile positioning device 2 includes a rear positioning device mounting plate 5, a measurement positioning device 6, a front positioning device mounting plate 16, a rear module slider 20, a front mold Group slider 21; the rear positioning device mounting plate 5 is installed on the rear module slider 20, the rear module slider 20 is installed on the rear linear module 24, and the front positioning device mounting plate 16 is installed on On the front module slider 21, the front module slider 21 is installed on the front linear module 25, and the measurement positioning device 6 is installed on the rear positioning device mounting plate 5 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com