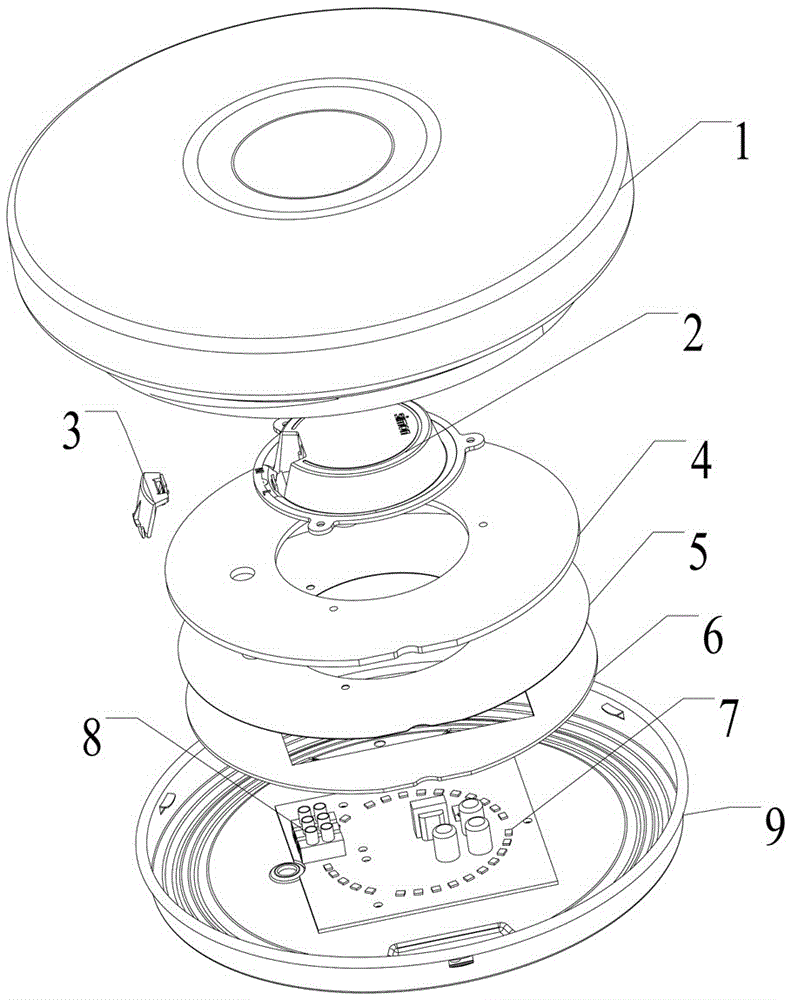

LED ceiling lamp with light guide plate

An LED ceiling lamp, light guide plate technology, applied in optics, light guides, light sources, etc., can solve the problems of high cost of lens molds, large differences in the light output effect on the surface of the mask, and high manufacturing costs, to simplify the production and assembly process, optimize the cost, Assembly of simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to describe the technical content of the present invention more clearly, further description will be given below in conjunction with specific embodiments.

[0039] In order to achieve the above object, the present invention adopts the following technical solutions:

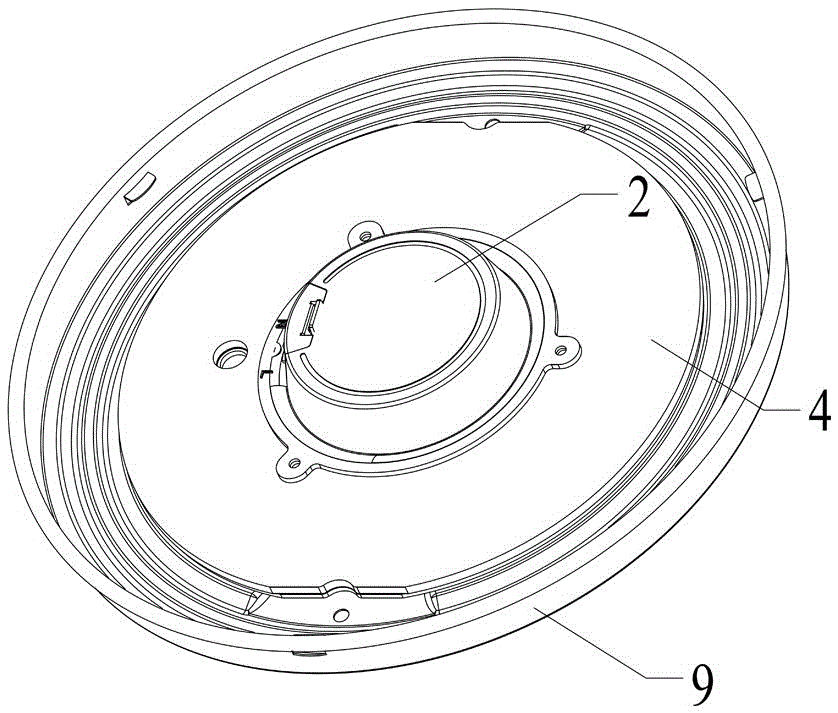

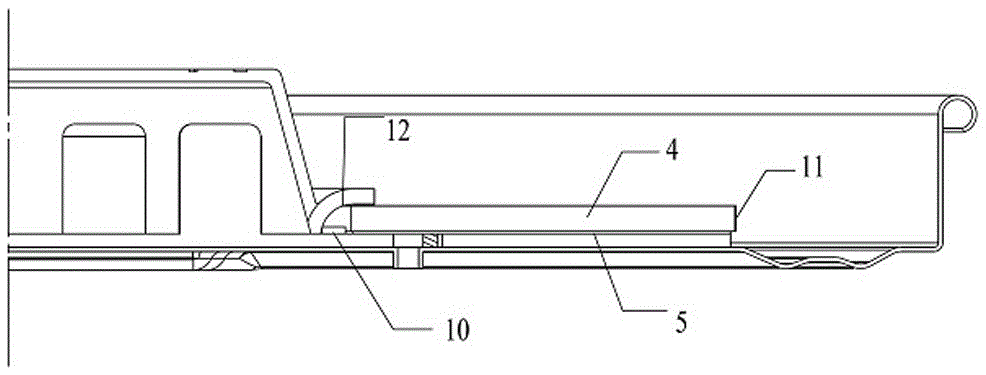

[0040] The light emitting mode of the point light source of the light source is designed as the light emitting mode of the surface light source, and the light emitting mode is converted by using the microstructure light guide plate, which simplifies the processing process, realizes cost optimization, simple assembly, and one model of light source can adapt to the light emitting effect of masks with different appearances. Has the following composition:

[0041] 1. The light source part of the lamp: the LED light source 10 and the power supply are concentrated on one PCB board, and the full patch process is adopted to avoid the arrangement of welding wires during the assembly process. The terminal 8,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com