Oil-free lubrication Kaplan turbine runner

An oil-free lubricated, hydraulic turbine technology, applied in the field of hydraulic turbine components, can solve the problems of reducing oil lubrication function, causing social problems, oil leakage and other problems, achieving smooth operation and reducing the risk of oil leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings, but it is not intended to limit the protection scope of the present invention.

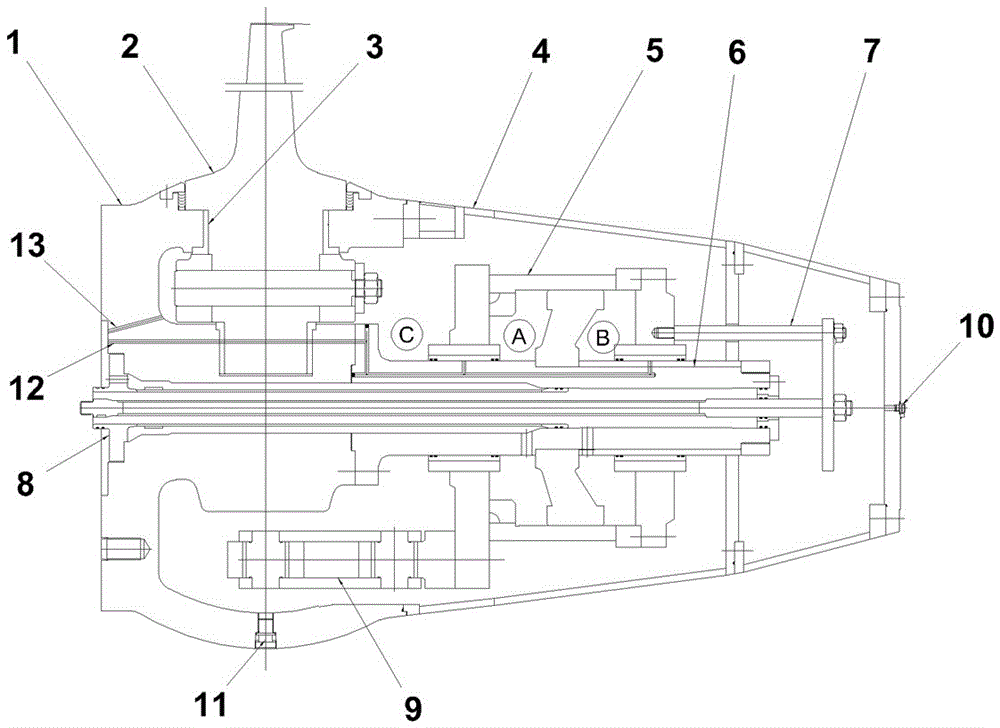

[0020] Such as figure 1 As shown, the oil-free lubricated paddle turbine runner. The blade 2 is operated by a blade servomotor 5 and a blade linkage 9 . The two cavities A and B in the blade servo cylinder are connected to the governor of the power station through the operating oil pipe 8, and the hydraulic oil is directly provided by the main part of the governor. C cavity in the hub body 1 injects a certain amount of clear water through the water injection hole 10 on the drain cone 4 before the unit starts for the first time, and it can be discharged through the drain hole 11 arranged on the hub body 1 during maintenance of the unit. The hub body 1 is also provided with a vent hole 13 for ventilating the runner during operation, and the vent hole 13 communicates with the atmosphere throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com