Wind power generation tower foundation with prefabricated foundation prestressed beams and slab

A technology of prestressed beams and foundations, which is applied in the direction of foundation structure engineering and construction, can solve the problems of increased cost, troublesome formwork support, long construction period, etc., and achieve the goals of reducing steel consumption, simplifying construction, and reducing the area of the foundation bottom Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

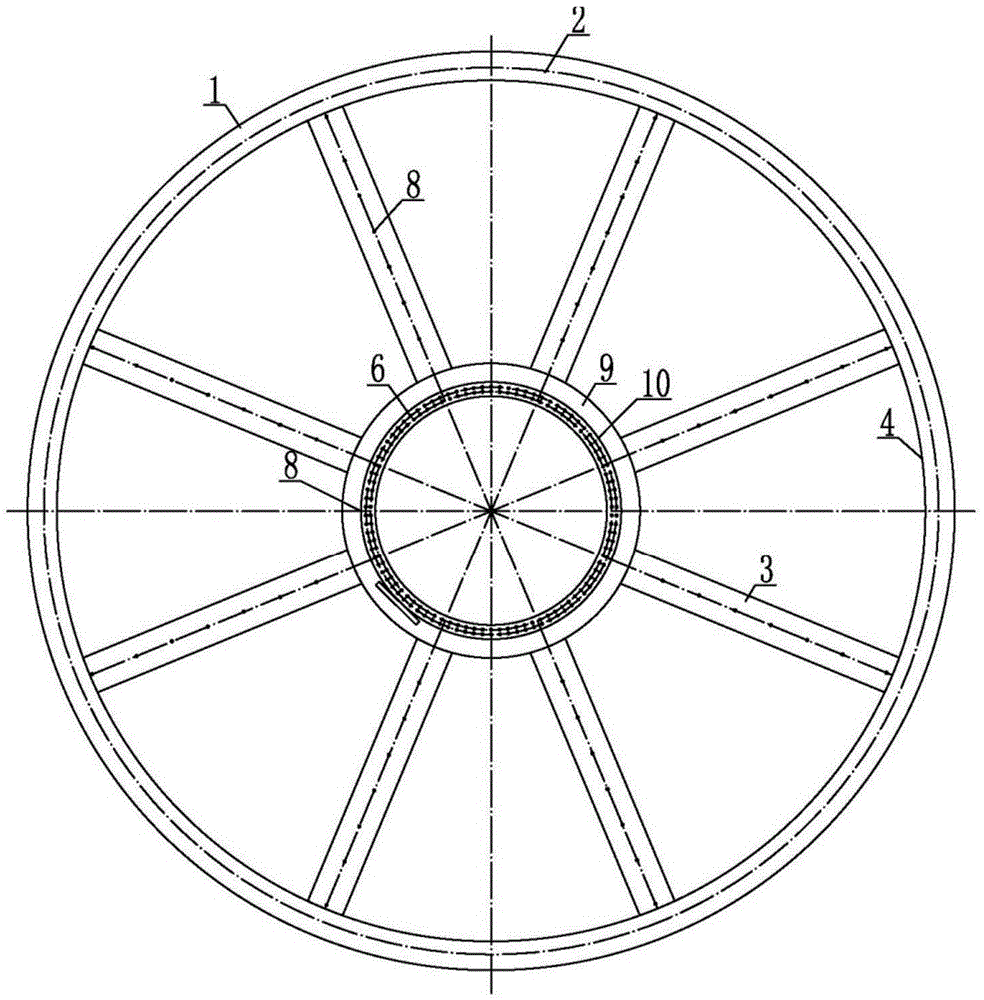

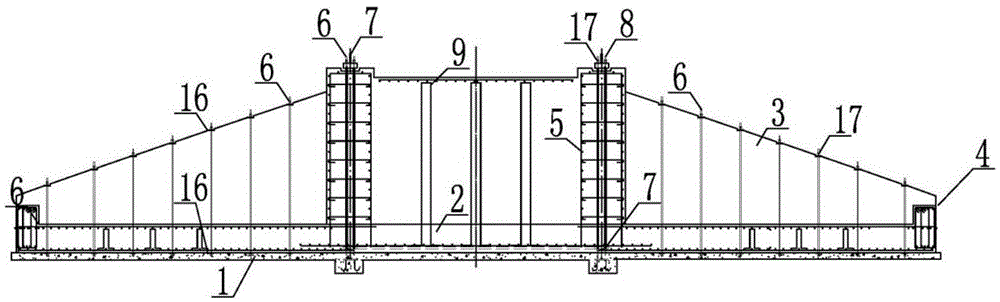

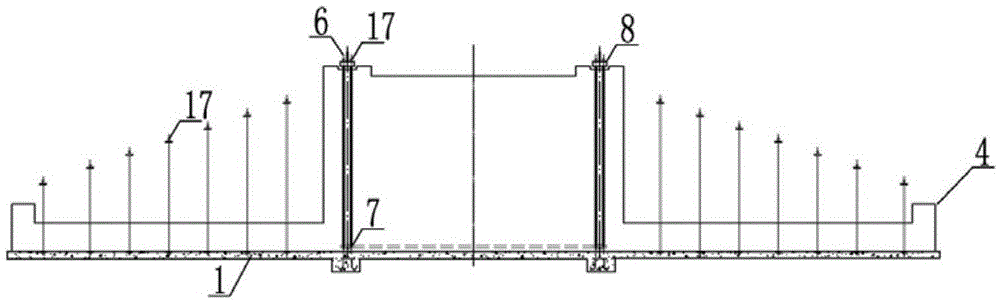

[0033] see figure 1 , 2 , 3, 4, and 5, the present invention includes: concrete cushion 1, concrete base plate 2, 8 hollow prefabricated cantilever beams 3, 8 hollow edge beams 4, concrete pier 5, prestressed anchor bolt 6, The concrete cushion 1 is in the shape of a ring. After the concrete cushion 1 is completed, the overall structure of the concrete base plate 2 and the concrete pier 5 is made on it. The middle part of the concrete base plate 2 is provided with a circular concrete pier 5 . At the same time, the finalized prefabricated cantilever beam 3 is manufactured in the concrete prefabrication production. A ring-shaped beam 4 is provided near the edge of the concrete base plate 2 . The prefabricated cantilever beams 3 are transported to the site and installed on the foundation of the wind turbine. One end of each prefabricated cantilever beam 3 is connected to the concrete column pier 5 to form a rice-shaped structure, and the other end is placed between two adjacen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com