A kind of compound refining method of magnesium alloy

A composite refining and magnesium alloy technology, applied in the field of alloy refining, can solve the problems of solvent slag inclusion, difficult operation, high refining labor intensity, and achieve the effects of reducing refining cost, improving refining quality and preventing combustion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

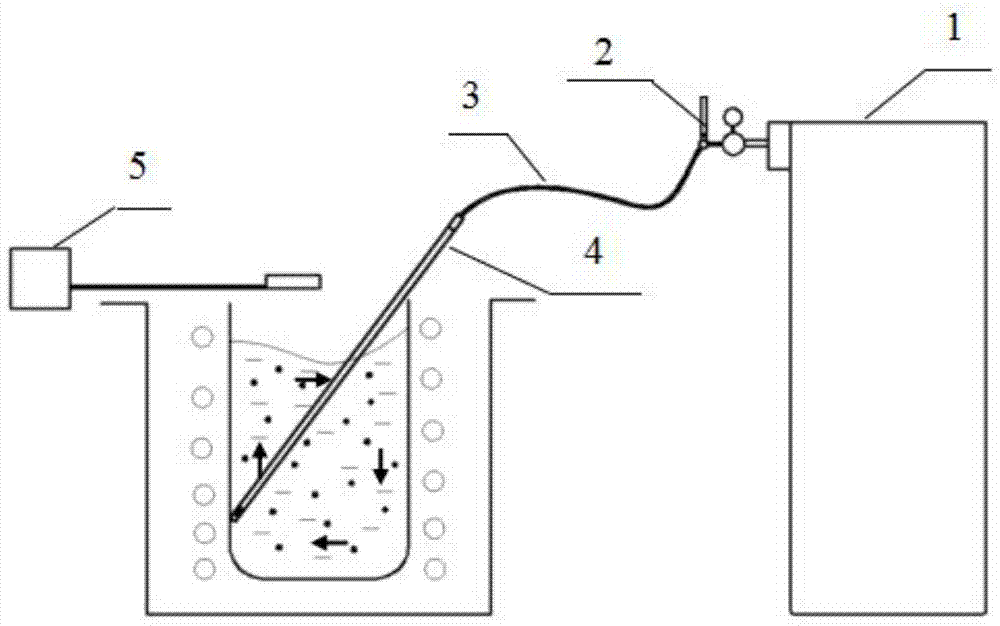

[0021] This embodiment provides a magnesium alloy ZM5 alloy consistent refining method; figure 1 The apparatus shown was carried out as follows:

[0022] 1) Put the thoroughly baked ZM5 alloy ingot into the furnace to melt, put it into a crucible (not marked in the figure), and after undergoing modification treatment at 720°C to 740°C, use a skimmer to remove the surface slag layer and spread a layer evenly No. 2 solvent is kept warm and left standing.

[0023] 2) Insert the air outlet end of the dried air guide tube (4) into the carnallite solution for washing, and then connect the washed air guide tube (4) to the air guide hose (3).

[0024] 3) Open the valve (1) of the argon gas supply system first, and then adjust the flow meter (2) until the argon gas flow rate is 1.2L / min~1.6L / min. Insert the air guide tube obliquely to a depth of 150-200mm from the bottom of the crucible.

[0025] 4) Turn on the solvent quantitative supply device (5) to keep the amount of solvent on ...

Embodiment 2

[0033] This embodiment provides a magnesium alloy ZM6 alloy consistent refining method; figure 1 The apparatus shown was carried out as follows:

[0034] 1) Melt the thoroughly baked ZM6 alloy ingot in a furnace, put it into a crucible, use a skimmer to remove the slag layer on the surface and sprinkle a layer of solvent evenly, and adjust the temperature to 740°C to 760°C to stand still.

[0035] 2) Insert the air outlet end of the dried air guide tube (4) into the carnallite solution for washing, and then connect the washed air guide tube (4) to the air guide hose (3).

[0036] 3) Open the valve (1) of the argon gas supply system first, and then adjust the flow meter (2) to a flow rate of 2.0L / min to 2.5L / min. Insert the air guide tube obliquely to a depth of 150-200mm from the bottom of the crucible.

[0037] 4) Turn on the solvent quantitative supply device (5) to keep the amount of solvent on the surface of the crucible constant, adjust the given rate of solvent to 150g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com